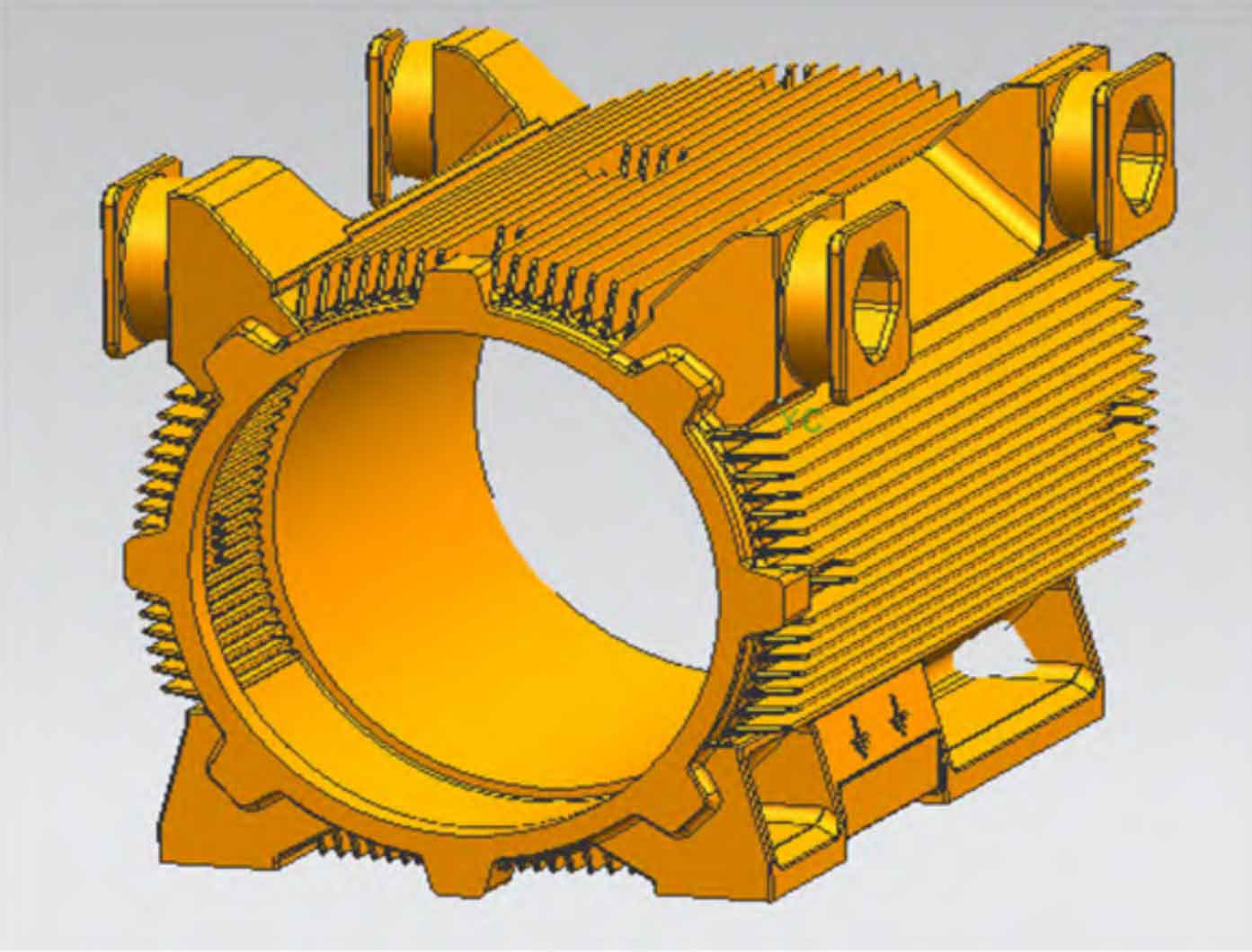

The chemical composition of the motor shell is: w (C) 3.15%~3.25%, w (Si) 1.6%~1.8%, w (Mn) 0.7%~0.9%, w (P) ≤ 0.05%, w (S) ≤ 0.1%. The lost foam casting shall be subject to stress relief treatment with a hardness of 180~230 HB. The furnace temperature shall be controlled at 1580~1590 ℃, the first pouring temperature shall be 1490~1500 ℃, the vacuum degree of lost foam casting shall be controlled at -0.065~-0.07 MPa, the casting time of lost foam casting shall be about 50 s, the pressure shall be stopped 10 min after pouring, and the unpacking time shall be controlled at 4 h. The metallographic structure of lost foam casting is graphite length grade 2, pearlite volume fraction>95%, tensile strength 240 MPa, hardness 190 HB.