At present, most of the gray cast iron produced has low strength and high residual stress. The mechanical properties and metallographic structure of the high-strength positioning plate require solid sampling, and there are high requirements for strength and hardness. Therefore, the research and development of the melting process of the positioning plate made of high-strength gray cast iron has great economic and practical value.

1) By adjusting the burden ratio and appropriate inoculation mode, the mechanical properties and matrix structure of the material meet the expected requirements: RM ≥ 300 MPa, body hardness ≥ 189hb, type a graphite rate > 85%;

2) The cast iron has no defects and the material of the cast iron has passed the production process verification.

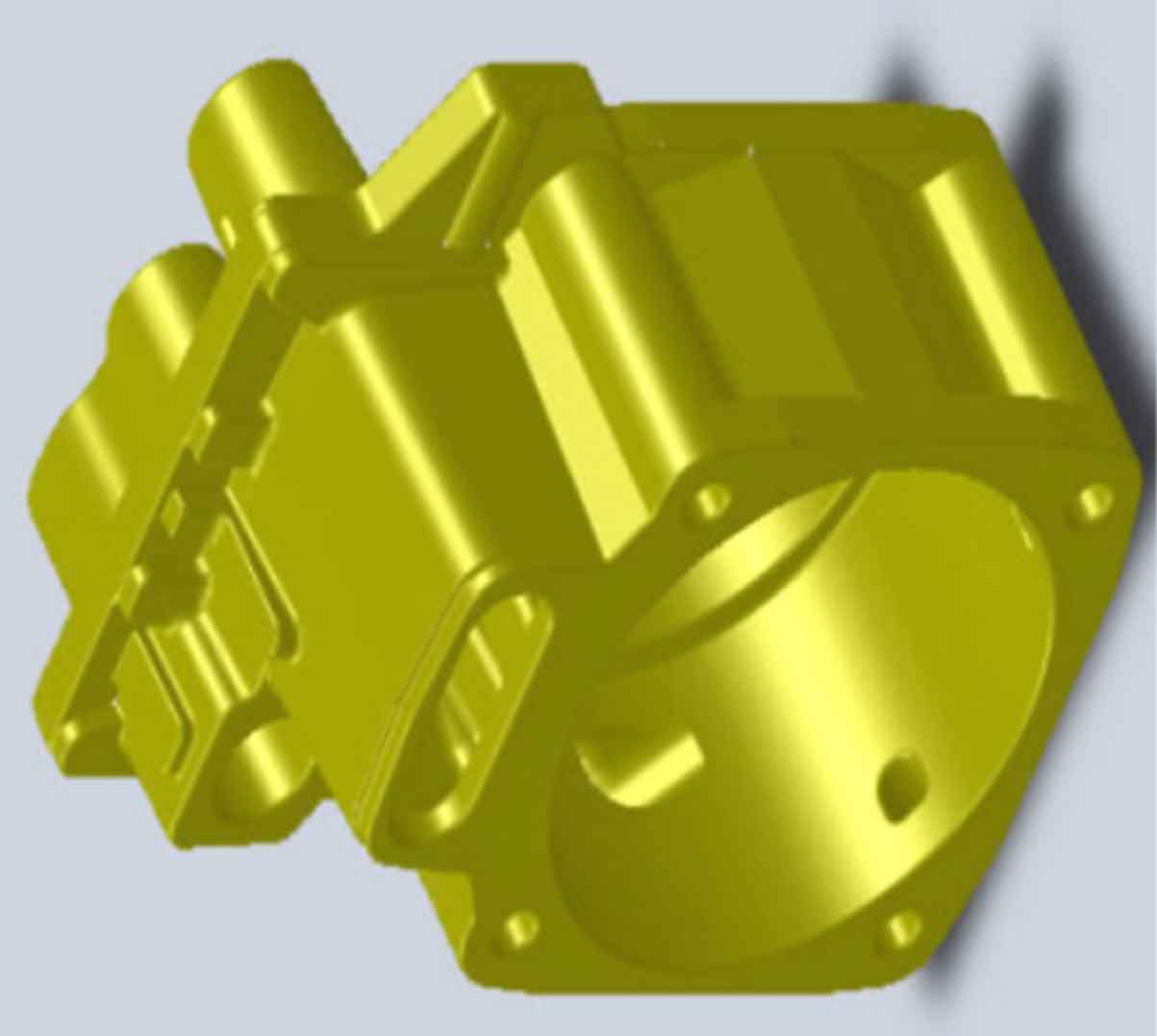

Through reasonable composition control and process control, the mechanical properties (solid drilling sample) of high-strength positioning plate meet the expected requirements: RM ≥ 300 MPa, body hardness ≥ 165hb, type a graphite > 85% Through the verification of solid products, the metallographic properties of the materials meet the requirements, and the castings MT and RT are free of defects, as shown in the figure is the three-dimensional model of the casting.