The source of cutting force is the resistance of the tool to overcome elastic deformation, plastic deformation and friction. The influence of cutting speed on cutting force is in two aspects: on the one hand, with the increase of cutting speed, chip deformation and friction increase, cutting force increases, and the impact of cutting force is obvious, and the value of dynamic cutting force increases in intermittent cutting. On the other hand, the increase of cutting speed leads to the increase of cutting temperature, the softening of materials and the decrease of cutting force. The cutting force in the process of PCBN milling vermicular graphite cast iron affects the cutting temperature and tool wear, and further affects the surface integrity.

During the experiment, the Kistler dynamometer is used to measure the milling force in real time. As shown in figure 1, the spindle rotates clockwise.

(1) The influence of cutting speed on cutting force.

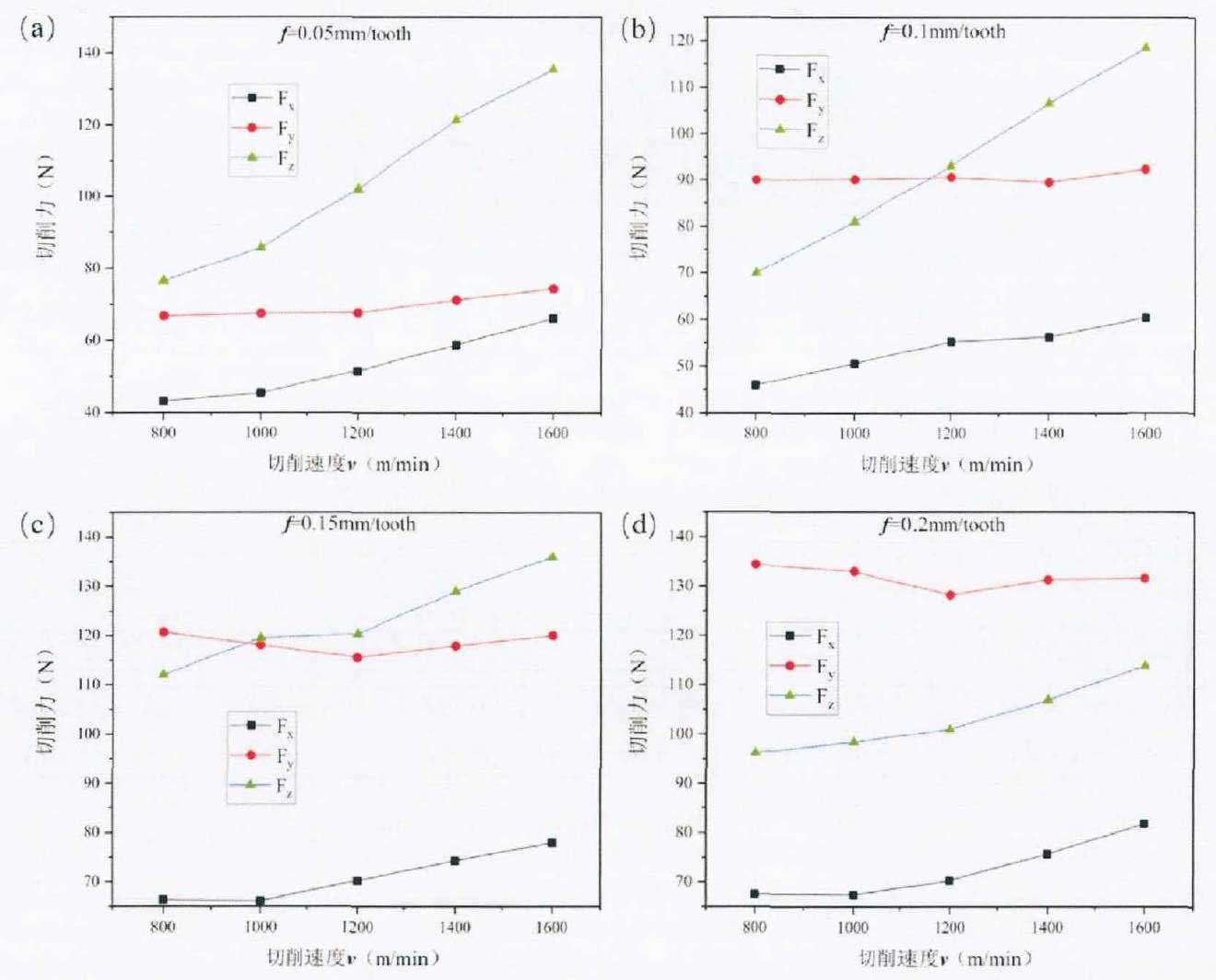

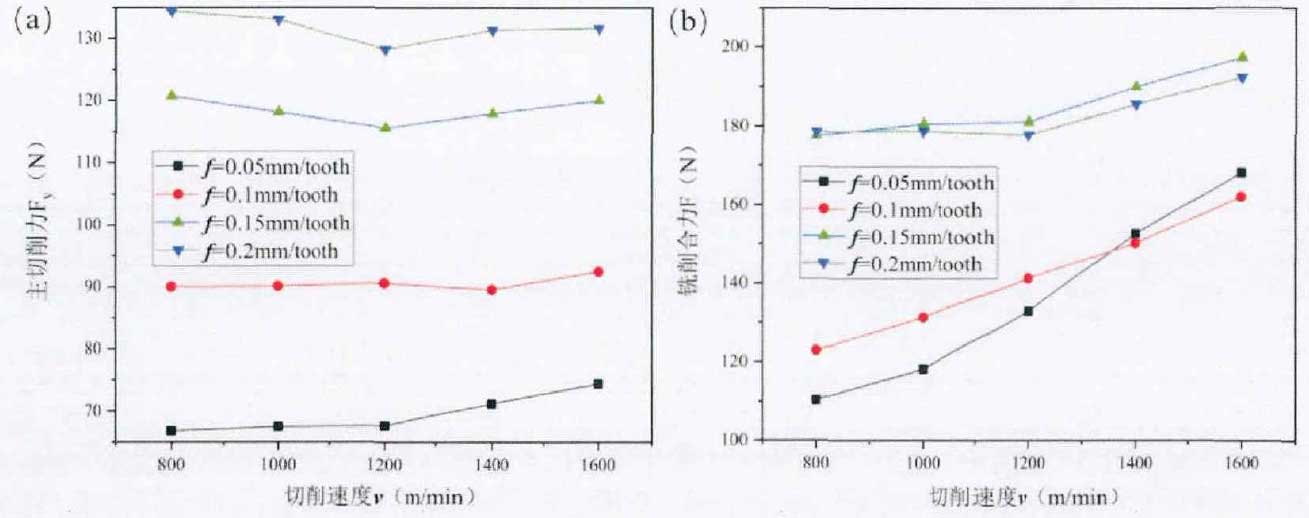

Fig. 2 is the cutting force measured by keeping the feed rate of 0.05mm/tooth, 0.1mm/tooth, 0.15mm/tooth and 0.2mm/tooth and separately lj at the ij speeds of 800m/min, 1000m/min, 1200m/min, 1400m/min and 1600m/min. The main cutting force is fy. As can be seen from figure 2, with the increase of cutting speed, the change trend of cutting force under each feed is basically the same, and the overall trend is increasing, and with the increase of feed, the increasing trend of cutting force slows down. This phenomenon can be explained that with the increase of feed rate and cutting speed, the thermal softening effect of the material becomes more and more obvious, and the cutting resistance decreases, resulting in a slow increase of cutting force. It can be seen from figure 3 (a) that the change of the main cutting force with the cutting speed is not obvious, and under the condition of large feed (f=0.15mm/tooth and f=0.2mm/tooth), the main cutting force decreases slightly and then continues to increase, this is because with the increase of the cutting speed, the thermal softening effect is greater than the strain strengthening effect, the cutting force decreases, and with the further increase of the cutting speed. The tool is easy to wear and increase the cutting force.

(2) The influence of feed rate on cutting force.

It can be seen from figure 3 (a) that the feed per tooth has a significant effect on the main cutting force, and the main cutting force increases proportionally with the increase of feed. The reason for this phenomenon is that with the increase of feed, the thickness of the material to be processed and the length of the shear zone become larger. However, it can be seen from figure 3 (b) that the milling resultant force shows a different rule. Under the condition of small feed rate (f=0.05mm/tooth and f=0.1mm/tooth), the milling resultant force at different cutting speed is not much different, and under the condition of large feed rate (f=0.15mm/tooth and f=0.2mm/tooth), the milling resultant force at each cutting speed has little difference. However, the cutting force increases obviously between small feed rate and large feed rate. As can be seen from figure 2, the small feed rate does not change much, but the axial cutting depth resistance decreases obviously, resulting in little difference in the washing force under the small feed rate. In addition, it can be seen from figure 3 (b) that the cutting force of f=0.15mm/tooth is larger than that of f=0.2mm/tooth as a whole, which can be explained by the obvious resistance to strain strengthening effect of thermal softening effect in f=0.2mm/tooth. And the minimum cutting force under the condition of large feed appears at the cutting speed of v=1200m/min and f=0.2mm/tooth.