The test piece shall be cut in the area where the casting defects are concentrated as far as possible in order to statistically analyze the characteristics of internal casting defects. Firstly, the NDT test shall be carried out on the typical node, and the NDT test methods are the same.

1. Test piece

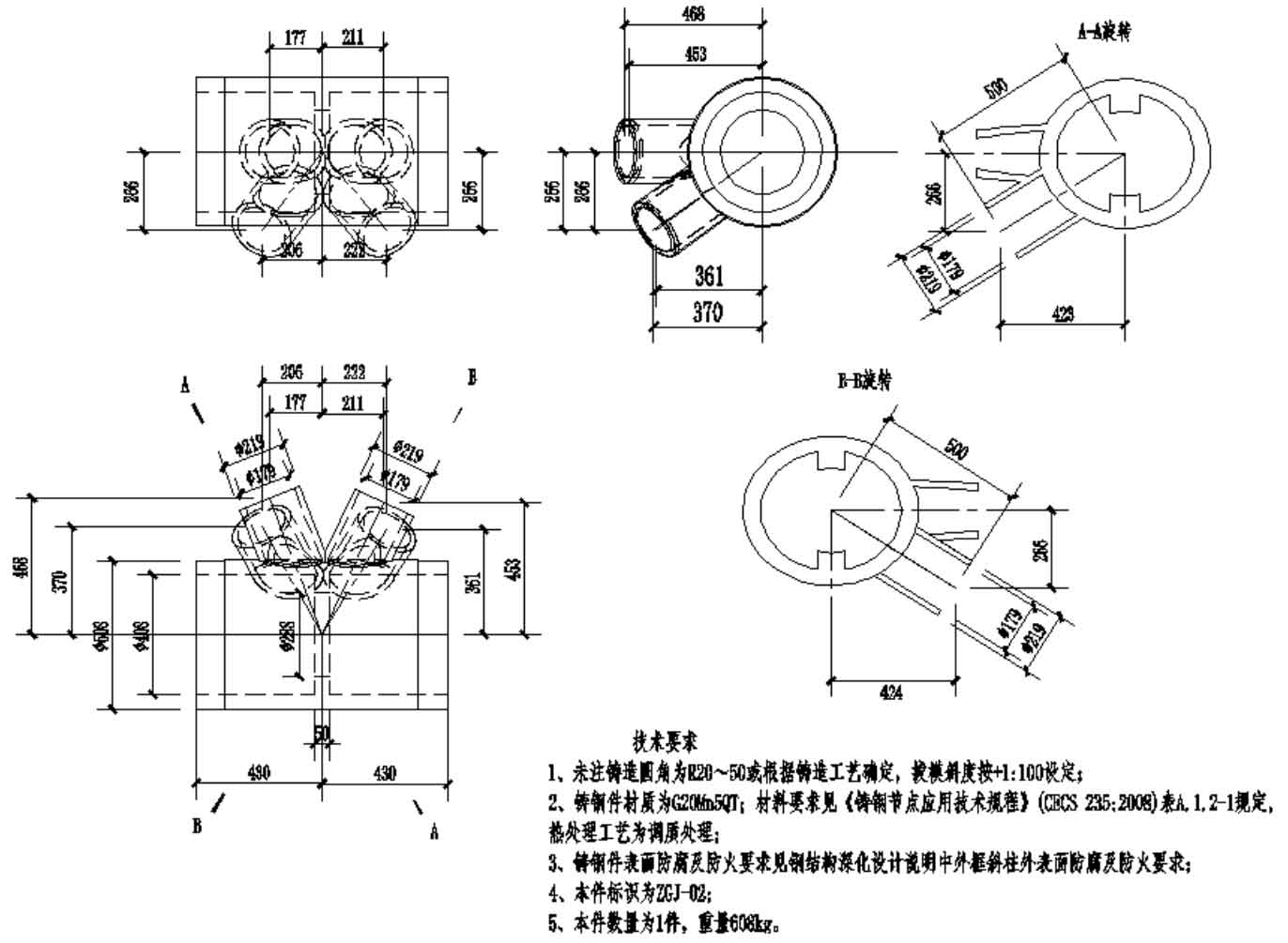

The test piece used in the slice test is a typical four branch cast steel joint in a project. The size of the test piece is 860 x 755mm and the weight is 0.608t. There is an annular stiffener in the middle of the main pipe of the cast steel joint with a thickness of 50mm. The node shape and size are shown in Figure 1 and Figure 2.

The test piece and 24 test samples of cast steel joints are produced by the same manufacturer, and the production process is completely in accordance with the actual production process. This node has the same material brand and material properties as the previous 24 nodes.

2. Test results

NDT and casting defect characteristic analysis:

(b) Flaw detection for lower profile of cast steel joint

The cast steel joint contains almost all casting defects, including cracks, delamination, inclusions, shrinkage porosity, pores and so on.

A total of 25 casting defects were found by NDT. It mainly includes:

(1) Three casting defects on the main pipe, i.e. dense shrinkage defects near the riser, delamination defects and point like dense defects;

(2) There are 4 casting defects in the lower mold of the main pipe, i.e. shrinkage and looseness of the rib plate and three point defects;

(3) There are 18 casting defects in the branch pipe, including 8 core support non fusion, 8 point defects and 2 cracks.

To sum up, the main casting defects of cast steel joints are: shrinkage defects near the riser of the upper mold of cast steel joints, serious continuous shrinkage defects at the bottom of the rib plate of the lower mold of cast steel joints, delamination defects of the upper mold of cast steel joints, incomplete fusion defects of mold braces and crack defects. See table for NDT test results of typical four branch cast steel joints.

| Defect type | Defect number | Defect location |

| Shrinkage defect | 1 | Near stiffeners |

| Crack defect | 2 | R zone |

| Delamination defect | 1 | Upper profile of cast steel joint |

| Shrinkage defect | 1 | Near riser |

| The core support is not fused | 8 | 4 branch pipes |

| Point defect | 12 | — |

According to the above NDT results, the casting defects are concentrated in the stiffener, riser and branch pipe, which lays a foundation for the next slicing.