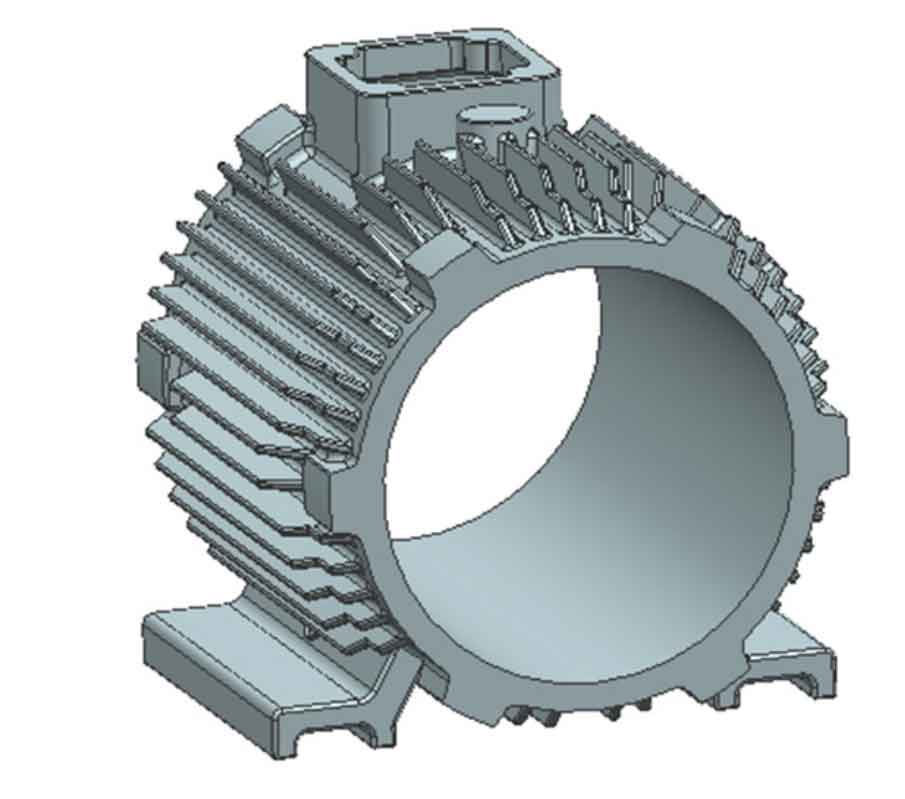

The nodular iron castings base plays the role of supporting and fixing the stator core in the motor. In the bearing end cover structure, the coordination between the base and the end cover plays the role of supporting the rotor and protecting the motor winding. There are many structural types of nodular iron castings base: integral base and separate base; There are cast iron base, cast steel base, steel plate welding base (including box base) and aluminum alloy die-casting base. However, from the perspective of production technology, there are two representative types: integral nodular iron castings base with feet and separate steel plate welding base. The former is the most commonly used base in small and medium-sized motors, and the latter is used for large hydro generators and DC motors with special requirements. The figure shows the three-dimensional model of a small motor base produced by ZHY casting, with material brand QT450-10 and overall dimension of 286 mm × 276 mm × 296 mm, maximum wall thickness 30 mm, minimum wall thickness 4 mm, casting mass 33 kg.

By comprehensively analyzing the casting defects of nodular iron castings and simulating with the help of CAE software, the form of the original process gating system is optimized, the melting and pouring parameters are optimized, and the optimized process scheme is verified and mass produced. In the production verification and continuous production, the quality of nodular iron castings is stable, It completely solves the problem of incomplete filling of the heat dissipation rib plate of this kind of thin-walled motor base. In addition, through the optimization of the original scheme, the nodular iron castings are filled stably in the whole pouring process, the temperature field is uniform, the flow rate of molten iron is reduced, and the scrap rate of nodular iron castings is greatly reduced. Combined with 3D printing technology, the scrap rate is reduced to less than 1.5%, which improves the appearance quality of nodular iron castings, reduces the cleaning workload and saves the production cost, The quality of nodular iron castings has been greatly improved.