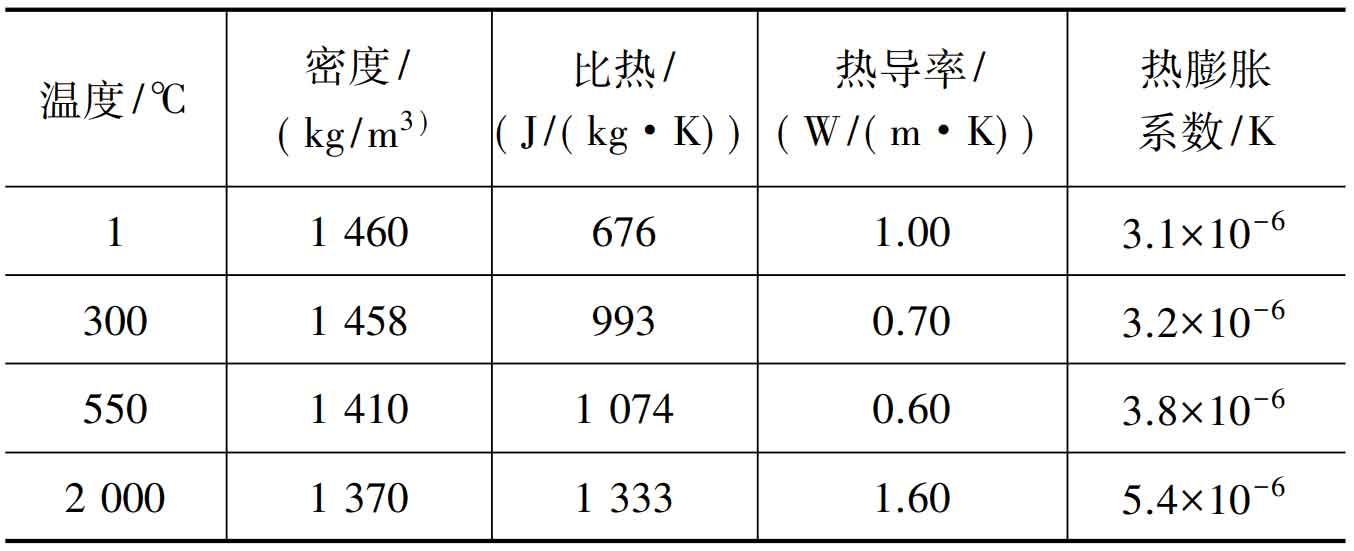

Draw the 3D pouring model of impeller casting process in Pro / E software, output STL file, and import it into numerical simulation software AnyCasting for numerical simulation. The casting, core and sand mold shall be made of the corresponding materials in dBASE material warehouse. The pouring time is 14 s, the pouring temperature is 720 ℃, and the furan resin sand and initial temperature are set to 25 ℃; The number of variable grids is expected to be 10 million. Although the more the number of grids is, the more accurate the numerical simulation results are, the more the number of grids is, the more complex the solution process is and the longer the solution time is, so the number of grids should be reasonable; The thermophysical parameters of furan resin sand and silicon aluminum alloy ZL111 are given in Table 1 and table 2 respectively. After the relevant parameters are set, the SOR iterative method is used to numerically simulate and solve the cast impeller.

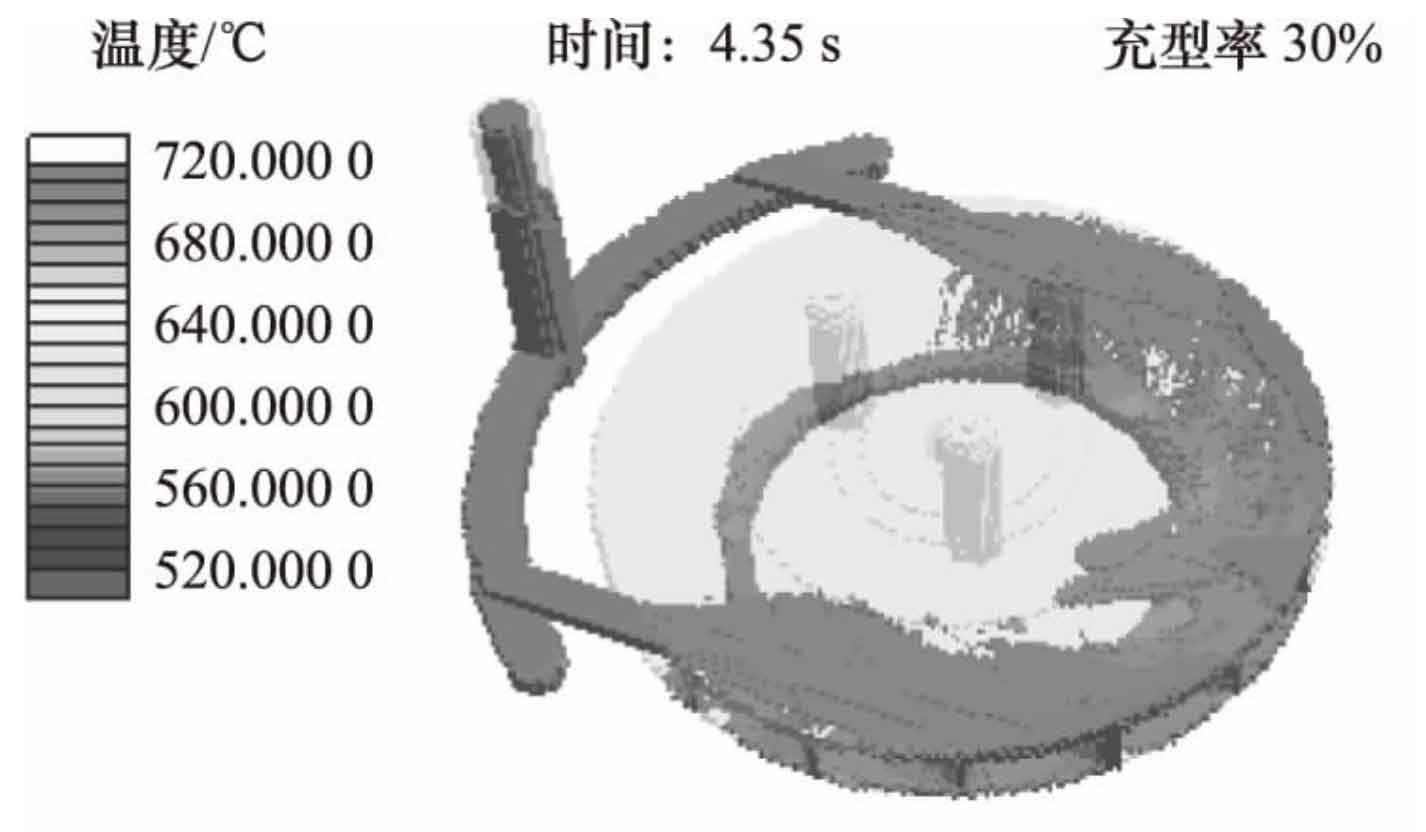

Fig. 1 is the distribution diagram of the temperature field during the mold filling process of the casting impeller, in which Fig. 1a is the mold filling process diagram when the mold filling time is 4.35 s. The temperature at the bottom of the casting impeller exceeds the liquidus temperature and reaches more than 700 ℃, and then it gradually remains in the liquid state.

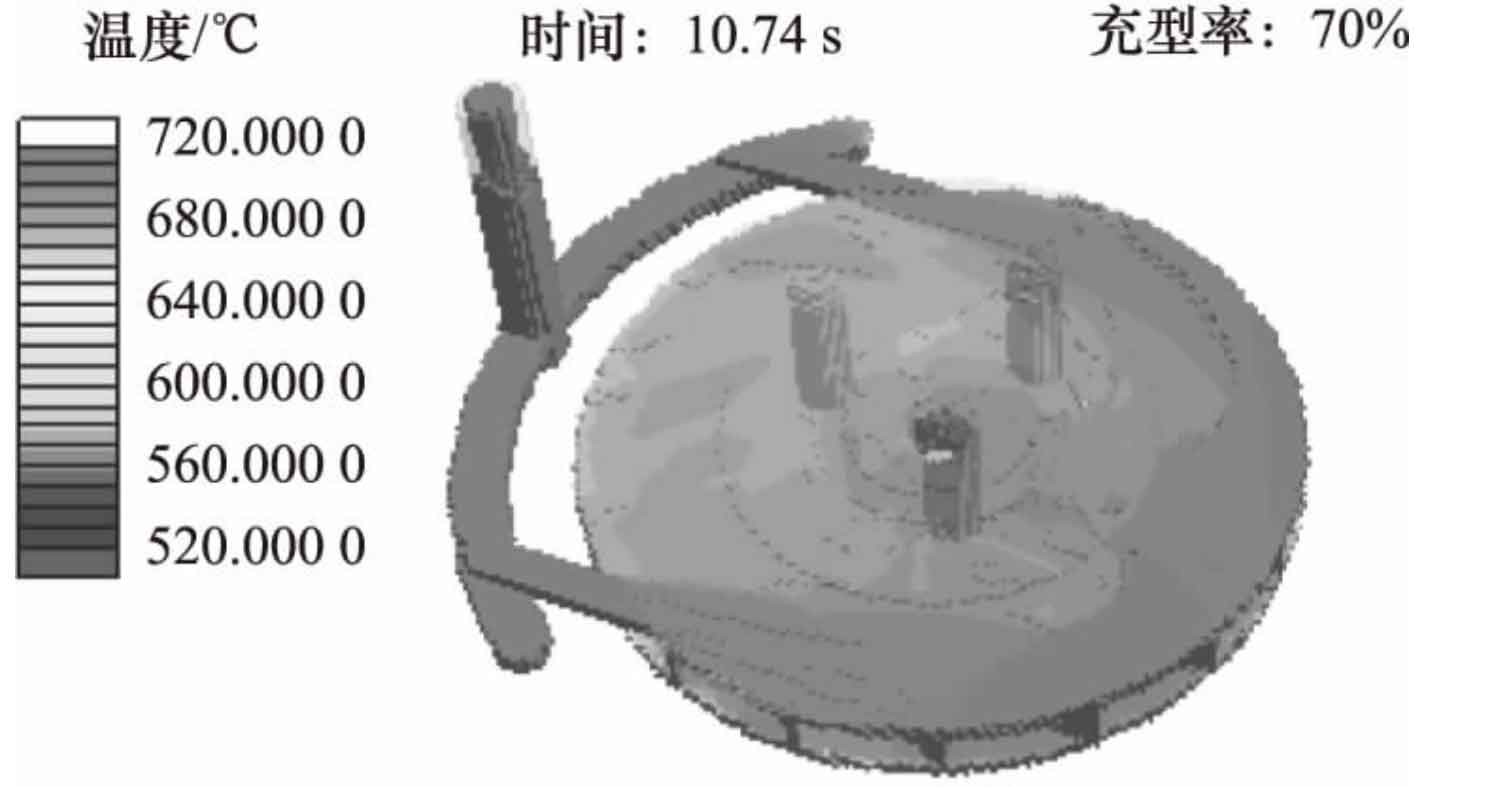

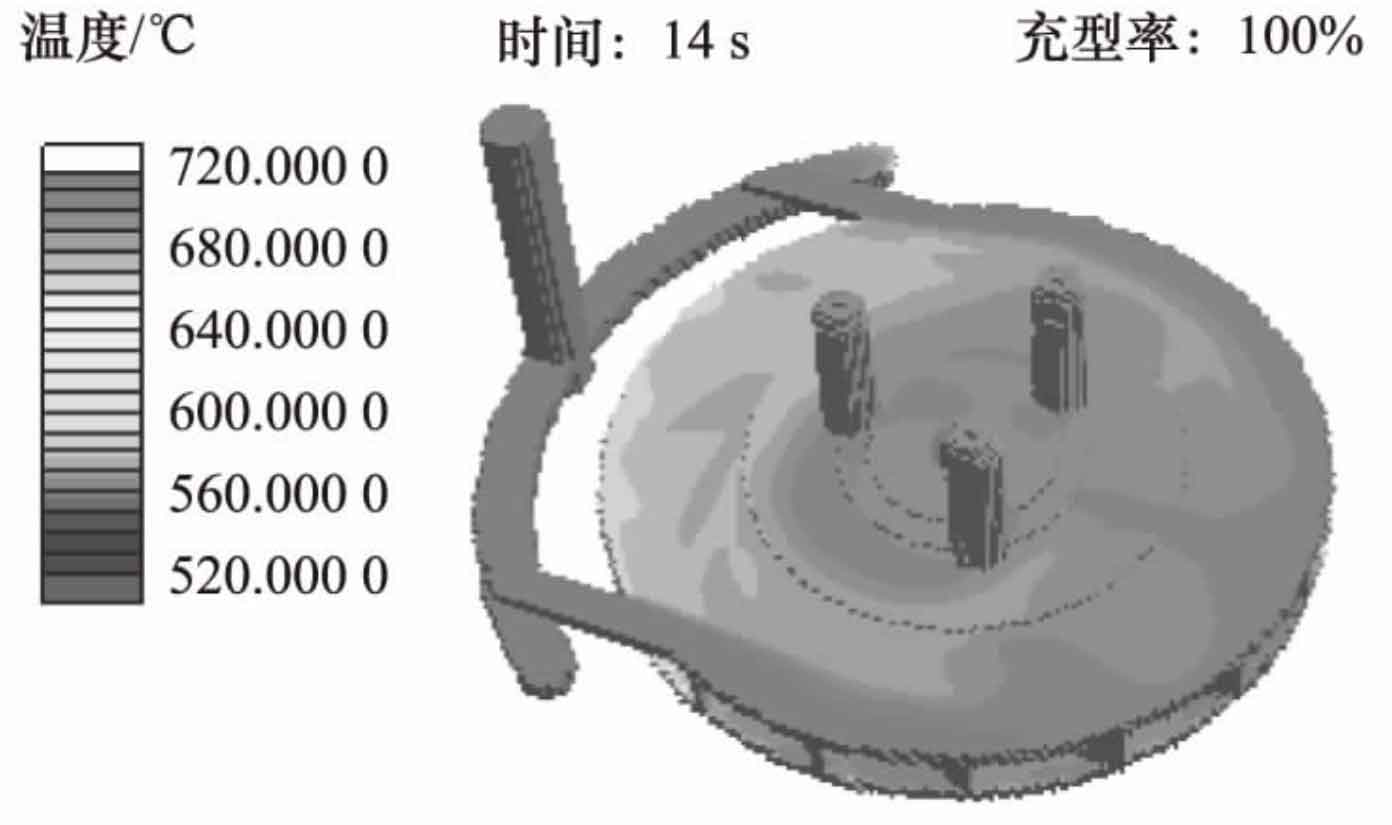

As the mold filling continues, the metal level in the impeller cavity of the casting rises gradually. As shown in Fig. 1b, when the mold filling time is 10.74 s, the bottom temperature of the casting has been reduced to 650 ℃, and the temperature at the far end of the bottom is still above 700 ℃. When the mold filling rate reaches 14 s, as shown in Fig. 1C, the mold cavity of the casting impeller has been fully filled, and the liquid level rises to the top riser area; The casting impeller adopts top pouring, which has good bottom-up effect in the mold filling process, and the mold is filled at the far end first. The flow rate of liquid metal is fast and stable. Although there is a certain fluctuation in the liquid metal level, there is no splash and obvious insufficient pouring in the whole process, which meets the technical requirements of impeller casting process.

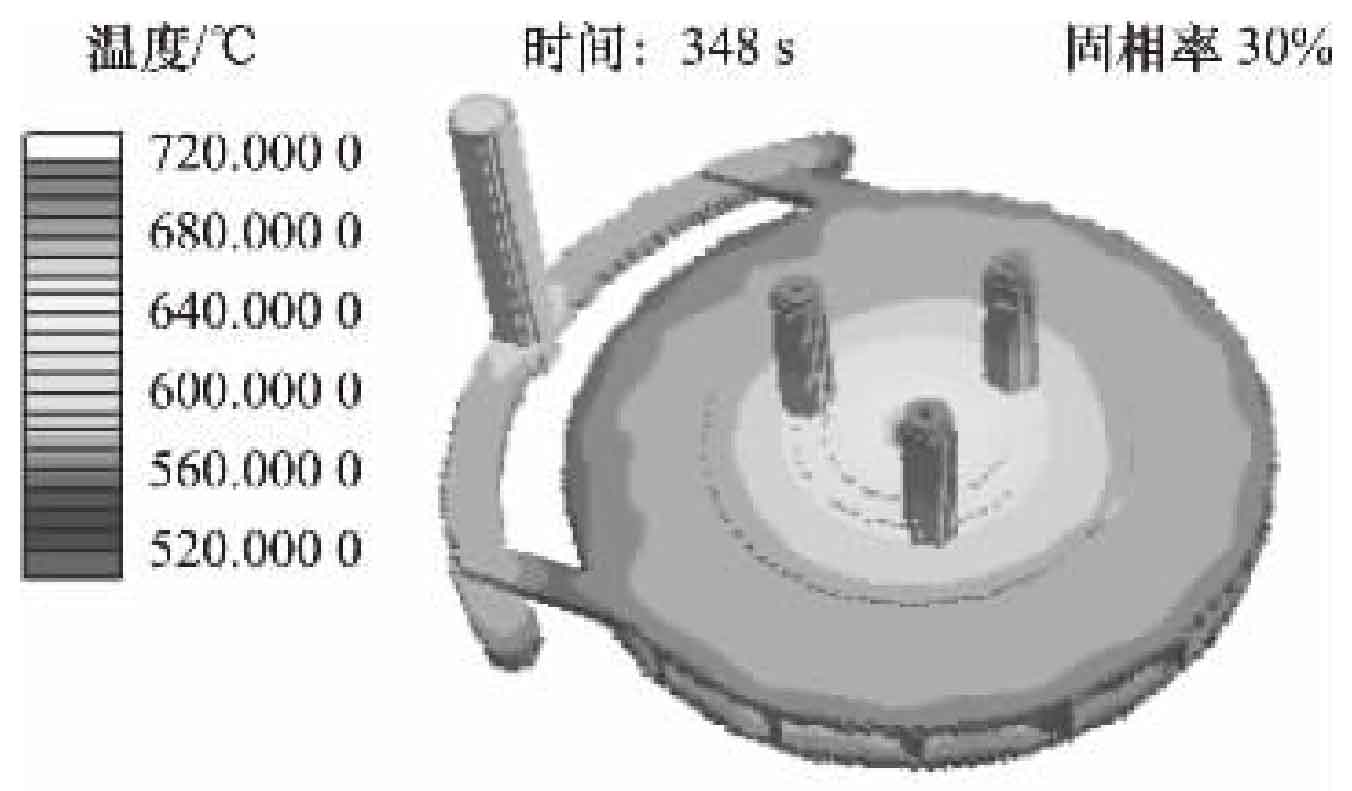

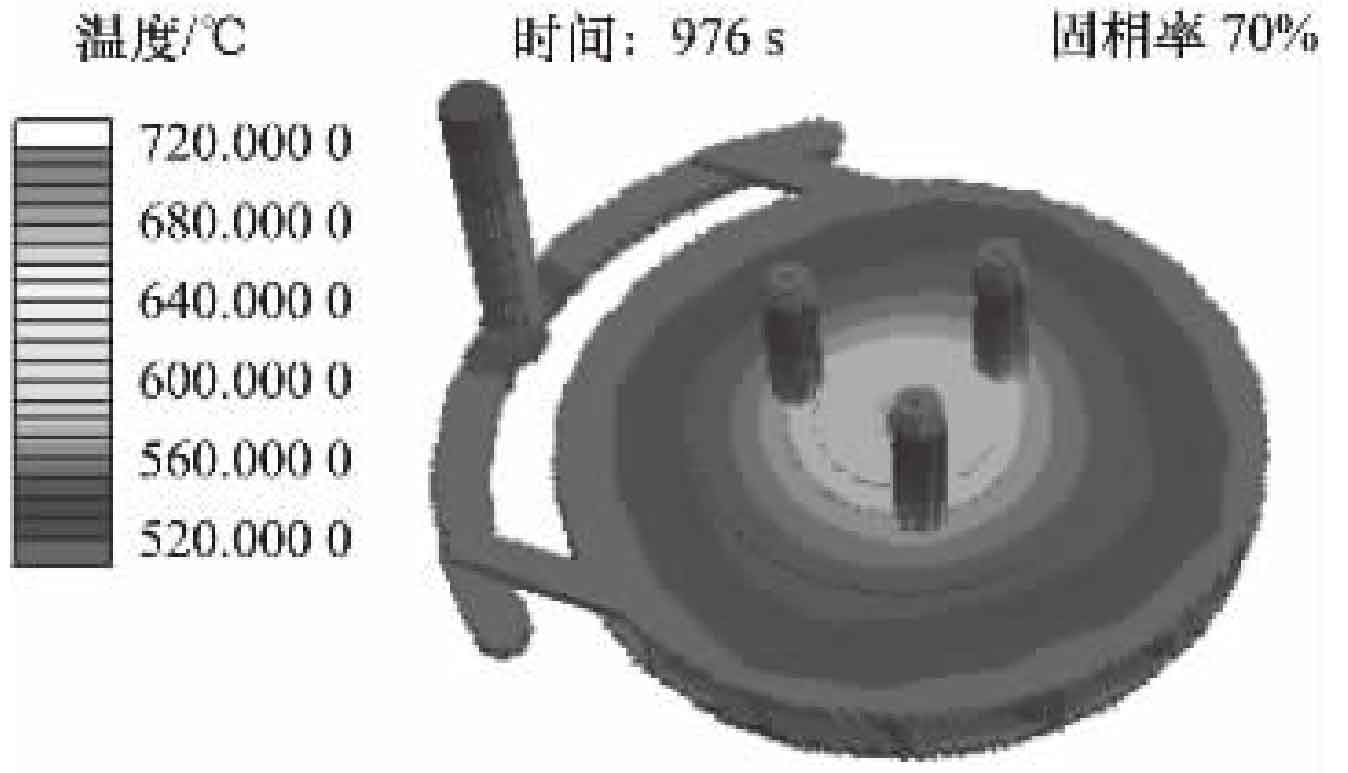

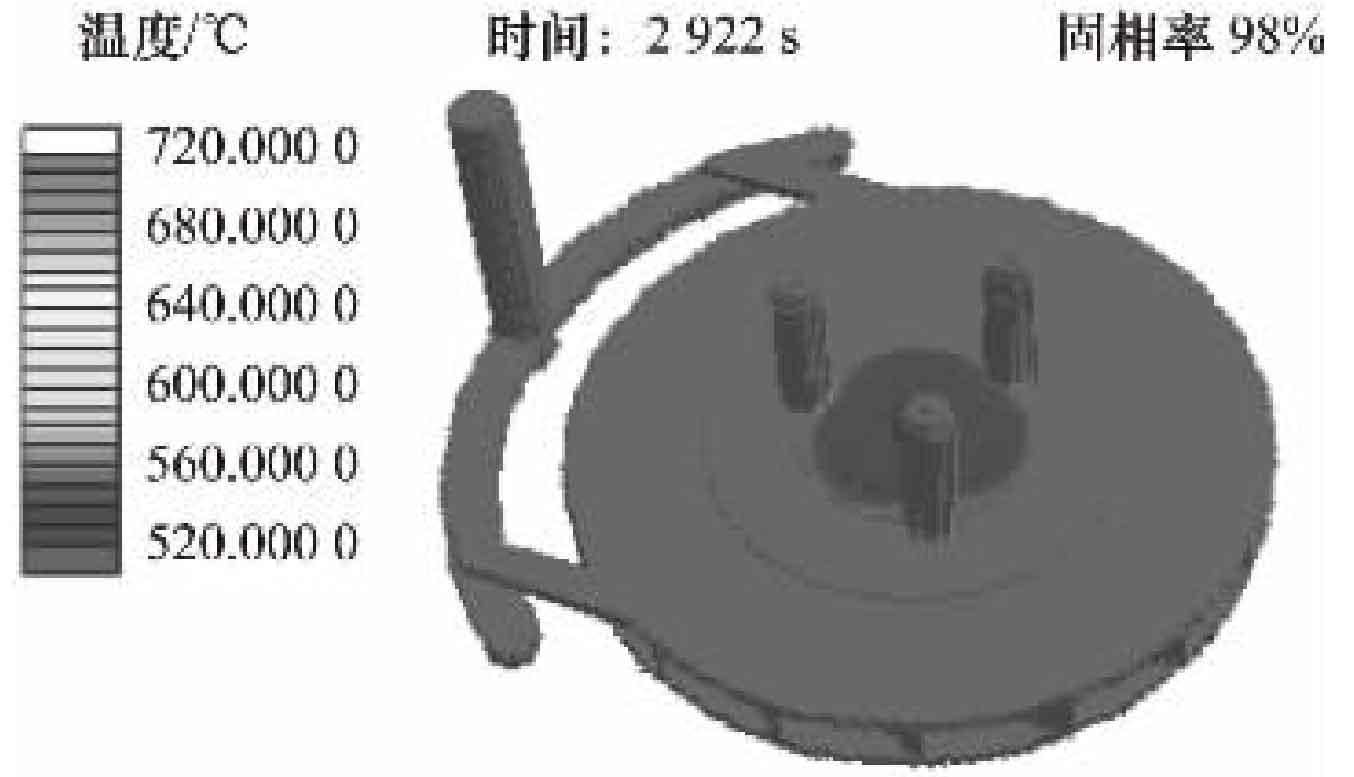

At the initial stage of solidification, the distal edge of the casting impeller begins to solidify first. Fig. 2A shows that when the solid rate is 30%, the thin-walled blades with small middle size at the upper and lower edges of the casting impeller gradually begin to solidify; Fig. 2B shows that when the solid content is 30%, the top riser also gradually begins to solidify with the passage of time, while the temperature in the central area of the cast impeller remains at about 620 ℃; Figure 2C shows that when the solid rate is 98%, the riser has completed solidification, and the temperature gradient in the central area of the whole casting impeller reaches 80 ℃. Therefore, the riser loses the feeding function. As the solidification process is coming to an end, the central circular hole area is the final solidification area, and there is a high probability of casting defects such as shrinkage porosity and shrinkage cavity. Therefore, the solidification sequence of the casting impeller is that the edge part is solidified first, the riser is next, and the middle thick part is the last solidification area. The complete solidification time is 3 538 s.