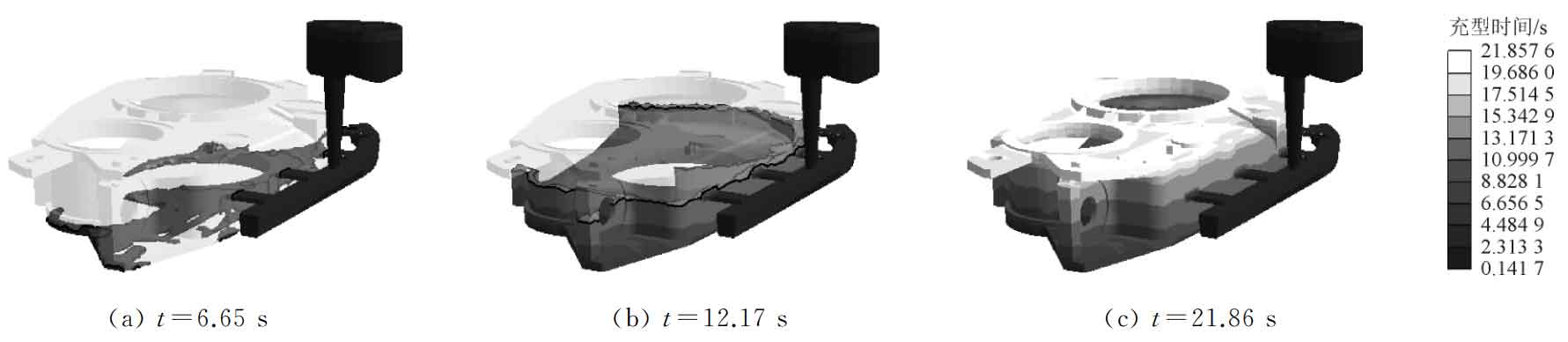

1. Simulation analysis of liquid metal filling process

The mold filling process simulation of sand casting is shown in Figure 1. It can be seen that the whole mold filling time is 21.86s. When t = 6.65s, the metal liquid enters the mold cavity smoothly through the sprue cup, sprue, transverse sprue and inner sprue, and the speed of the metal liquid passing through the inner sprue is low. In the process of flow, it enters the top of the mold cavity along the cavity wall without causing great impact on the sand mold and the bottom of the mold cavity; When t = 12.17s, the metal liquid fills the mold from the bottom of the cavity to the top of the cavity in turn, and there is no obvious air entrainment; When t = 21.86s, the molten metal completely filled the cavity without defects such as insufficient pouring and cold shut. Therefore, the gating system can realize the sequential filling of liquid metal.

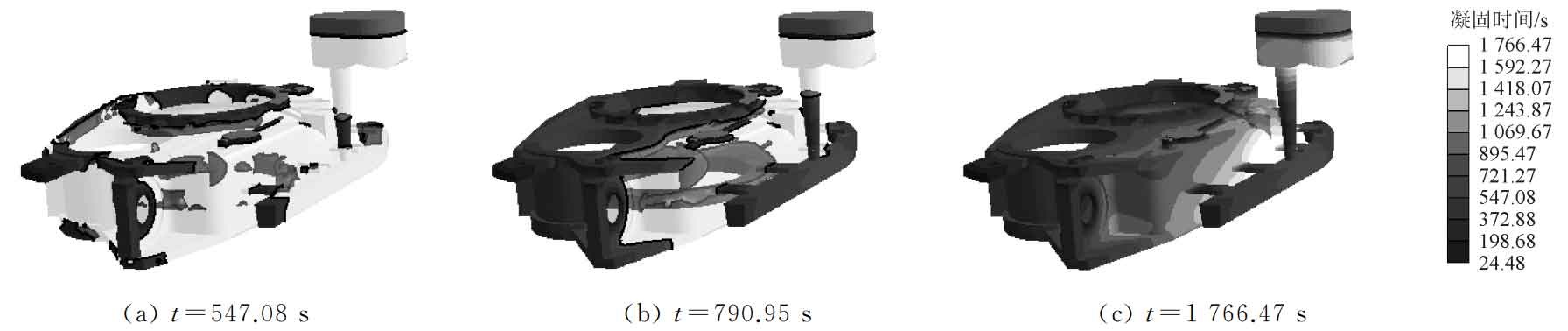

2. Simulation analysis of solidification process of sand casting

Figure 2 shows the simulation results of solidification process of sand casting. It can be seen that the total solidification time of sand castings is 1766.47s. When t = 547.08s, due to the uneven thickness of the mold cavity of the sand casting, the cooling speed is faster where the thickness is small, and solidifies first; When t = 790.95s, with the decrease of temperature, the solid layer increases and the liquid layer decreases, and the sand casting solidifies layer by layer; When t = 1766.47s, the thickness of the bottom of the box is large, so the cooling speed is slow and becomes the last cooling position. There may be shrinkage, porosity and other defects here, but generally speaking, the solidification process is sequential solidification.

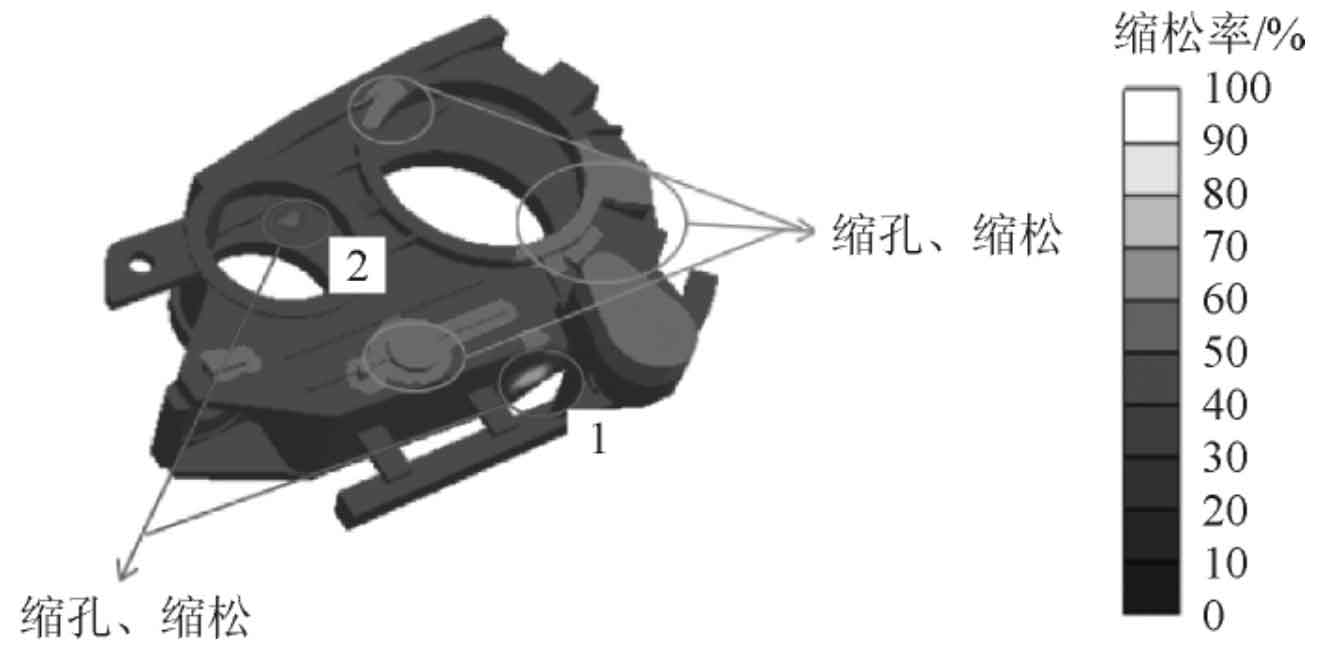

3. Simulation analysis of sand mold casting defects

The simulated distribution of defects in sand castings is shown in Figure 3. It can be seen that there are two obvious defects in the sand casting. Combined with the solidification process of the casting, both places 1 and 2 are the last solidification positions, so it can be concluded that these two defects are shrinkage porosity and shrinkage cavity. In addition, there are many shrinkage cavities on the upper surface of sand castings.

Through the simulation, it can be concluded that the mold filling process of the process scheme is very smooth, and the design of the gating system is basically reasonable, but the solidification process is not stable enough, resulting in many defects, which need to be optimized.