Introduction

Aircraft jet engines, marine gas turbines, industrial gas turbinesturbines are commonly used to drive machinery in many fields, such as power generation, and high-temperature gases are often used to drive turbines.As an important component of turbines, the blades of the turbine need to withstand high temperatures,The harsh environment of hot corrosion (typical gas turbine operating temperature exceedshigh temperature alloy has good oxidation resistance, thermal stability, fatigue resistance, and good creep rupture resistance.Therefore, it isThis environment has been widely used.K213 is a kind of iron-nickel-chromium-based cast high-temperature alloy, in whichAl and Ti, forming the γ’ phase, and achieving precipitation strengthening, which is characterized by the presence of WSolid solution strengthening is performed to strengthen the grain boundary with a trace amount of B. This alloy is castExcellent process, good comprehensive performance below 750℃.In recent years, high temperature alloy components tend to be precision and thin-walled, due toThis will put higher demands on precision casting technology.Traditional experimental workArtistic creation has high trial and error costs and long cycles, while computer-aided designThe design can greatly reduce the cost of trial and error and shorten the process design cycle.There are precedents for using computers to simulate the solidification process of blade casting.The Iron and Steel Research Institute has adopted computer simulation for precision casting of high temperature alloys, which is the mostThe optimal process plan was finally determined, which significantly reduced casting defects and loweredThe production cost is reduced.Shenyang Aerospace University adopts finite element analysisSimulated the filling and solidification of K438 alloy liquid in investment casting processThe process has determined the optimal casting system and process.Harbin Institute of TechnologyThe university simulated the forming process of TiAl-based alloy blade suction casting, and analyzedThe causes of defects in the blade during mold filling and solidification were analyzed, and the phaseThere are also many scholars abroad who have applied high-throughput methods and mathematicalValue simulation is combined and applied to optimize the process parameters of precision castingto quickly and accurately optimize key process parameters and improve the quality of castings.Comprehensive performance.The author aims to solve the problems of complex shape of high temperature alloy blades and the precision casting processDefects and other problems are prone to occur in the process of casting, so the MAGMA casting simulation software is used to simulate the casting process.The application of the proposed K213 high temperature alloy in the typical blade process of precision investment castingThe filling and solidification process of the mold, mainly the fluid velocity of the melt during the filling processDistribution of temperature field, distribution of solid fraction during solidification process, distribution of voidssimulation study on distribution, etc., through the analysis of the location of porosity prone to occur in castingsto determine and verify the reliability of the designed pouring system, and to provide technical support for field trials andProvide reliable theoretical basis for production.

1 Test method

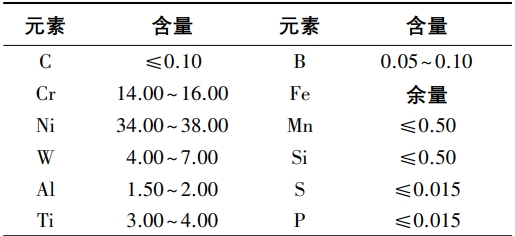

K213 casting superalloy master alloy was selected for testing, and its chemical composition wasThe chemical composition is shown in Table 1.The melting point of K213 alloy is 1324-1361℃.℃, density ρ = 8.14 g /cm3The expansion coefficient is between 20 and 800℃18.61×10-6℃ -1。

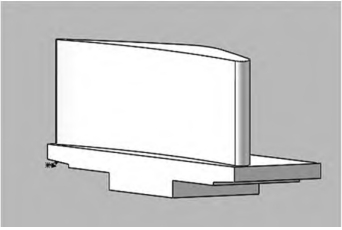

The K213 alloy blade was simulated using the MAGMA casting simulation software.The casting process of the mold is simulated, and the casting process is analyzed through the filling and solidification processes.The formation and distribution of temperature field and defects during the manufacturing process can provide valuable information for practical production.Provide guidance on the correct process method.Use gravity casting, gravity casting,The speed is 9.8 m/s.The basic parameters have a weight factor of 0.8 and a relaxation factor of1.6, initial time step size 0.0001 s, casting and air, casting and castingThe heat transfer coefficient between the types is 0.023, and the casting temperature is 1550℃.The casting is a complex blade shape, using SolidWorks 3D solid modeling software.The body modeling software is used to model the entire pouring system, using top-pouring squareThe alloy blades are poured in one time, with a single blade weighing 3 kg.The mouth and runner provide shrinkage compensation for the solidification process of the blade.MAGMA is usedThe casting simulation software is used for grid division, and the grid parameter is selected as 1 mm.

2 Results and analysis

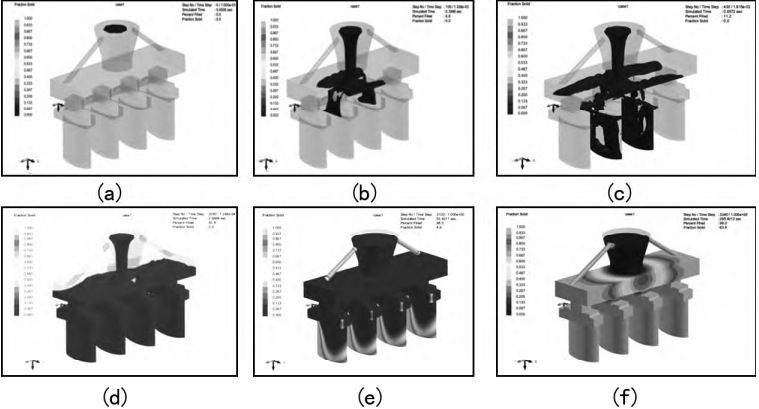

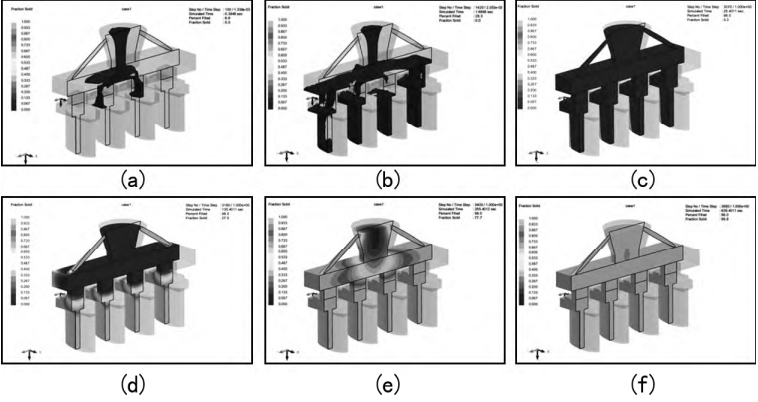

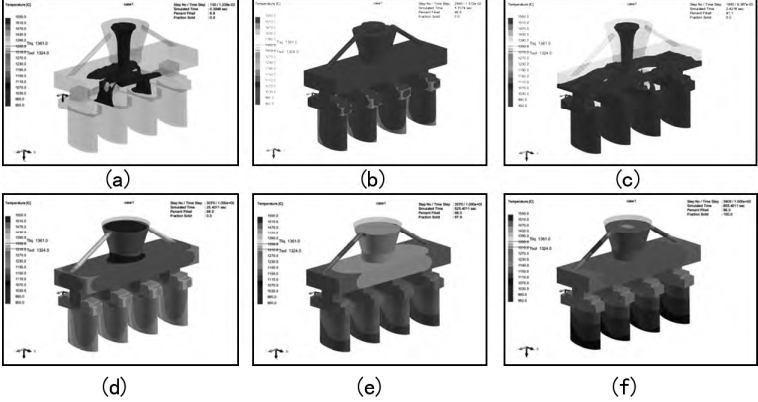

2.1 Solid fraction during filling processFigures 2 and 3 show the solid fraction during the filling process, where the verticalThe internal solid fraction distribution of the blade and the pouring system can be observed in the cross-sectional view.As shown in the figure, the alloy liquid is always in liquid state during the casting process at the blade part.state, can achieve complete stamping of the blade part, 15 s stamping is completed, 25 sWhen the cooling water starts to freeze at the edge of the blade, the runner is opened.The initial solidification and final solidification occur at the connection between the gate and runnerThe center of the gate can be used to place the final solidification area at the junction of the gate and runner.

2.2 Simulation results and analysis of temperature field

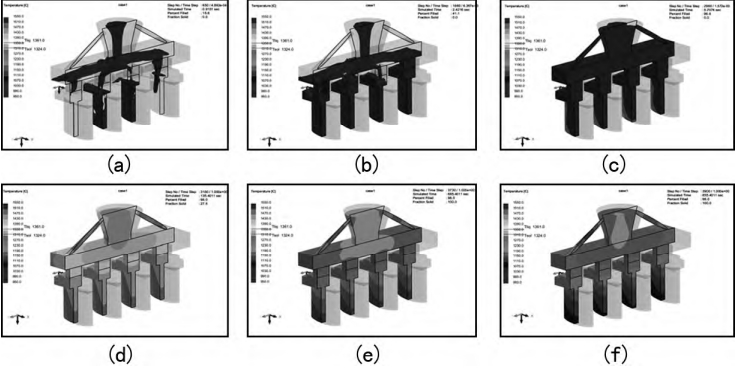

Figures 4 and 5 show the temperature field distribution during the pouring process, where theThe longitudinal sectional view can observe the temperature field distribution inside the blade and the pouring system.From the figure, it can be seen that the alloy liquid is always in a high temperature state during the casting process at the blade location, with a temperature of approximately 1500℃ throughout the process. After 3 seconds, the bladeAfter the part is stamped, the temperature at the edge of the blade begins to decrease, with a minimum temperature of approximately1400℃, still higher than the melting point of the alloy, making it less prone to defects.15s stampingAfter completion, the temperature of the edge area of the blade dropped to about 1230℃.The analysis results of the combined images 2 and 3 indicate that the condensation begins on the edge of the leaf at 25 seconds.After 15 minutes, at the center of the connection between the gate and runnerThe temperature is still around 1300℃ and remains in a high temperature state, with the restThe temperature of the part has dropped below the melting point.This indicates that the designed gate and crossThe runner can provide shrinkage compensation for the blade part.

2.3 Simulation results and analysis of fluid velocity field

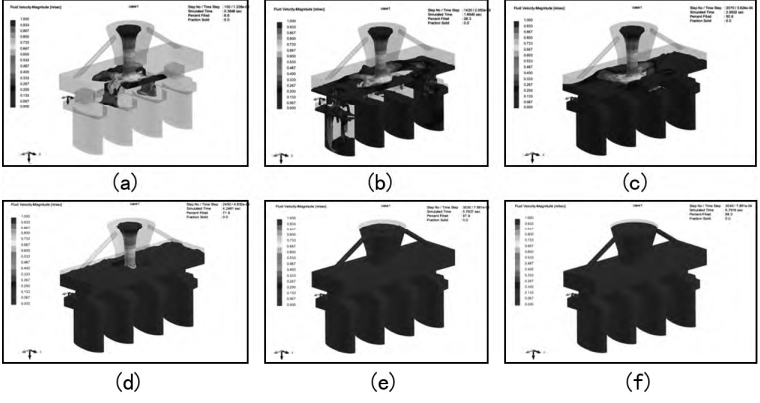

The figure shows the simulation results of the velocity field during the filling process.As shown in Figure 6,At 3 seconds, the blade part is completed, but there is still disturbance at the edge of the blade, as shown inThere is a small amount of rolling behavior in the two outermost blades. As theWith the continuous casting, this disturbance will not cause casting defects.The alloy flow at the blade position is completely static at 5 seconds, and the casting is poured at 15 secondsAfter that, it can be observed that there is a significant decrease in the gate liquid level, indicating that the gateThe runner and the horizontal runner play a good role in shrinkage compensation.

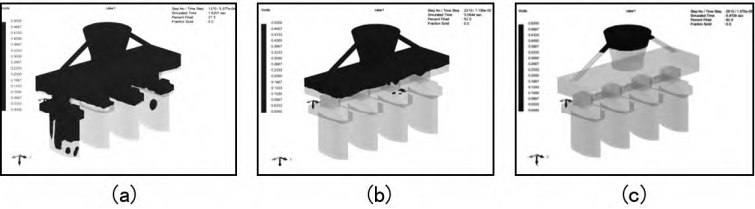

2.4 Simulation results and analysis of voidsThe figure shows the simulation results of voids during the pouring process.It can be seen that during the pouring process,During the injection process, the centers of the outermost two blades may be disturbed due to the pouring process.A void is formed, but as the pouring progresses, under the action of the pressure of the molten metal,The voids continue to rise and eventually concentrate at the gate and runner.

3 Conclusion

This article focuses on the research of K213 high temperature alloy in precision investment casting filling process.Fluid velocity field during solidification process of M-type, solid fraction distribution during solidification processThe distribution of cloth, temperature field, and void distribution were simulated using MAGMA casting simulation software.True simulation research, through analysis of simulation results, obtains porosity of castingsThe possible locations verify the reliability of the pouring system.Conclusionas follows.(1) The alloy liquid is always in liquid state during the casting process of the blade part,The complete punching of the blade part can be achieved.After the blade solidification is completed, the crossThe runner begins to solidify, and the final solidification occurs at the junction of the gate and the runner.The center of the connection part.(2) The temperature field simulation results show that after filling the mold, the blade edgeThe edge first begins to cool down, with a gradient increase in temperature from the top of the leaf to the gatePlus: The center of the connection between the gate and runner is always at high temperatureThe temperature of the remaining parts drops below the melting point.(3) The simulation results of the overflow field and voids indicate that during the initial filling stage, theThere is a small disturbance in the blade area, and the alloy flow in the blade area is completely static at 4 secondsStop;after the casting is poured, it can be observed that the liquid level of the riser has significantly decreasedSigns: The final solidified voids are concentrated at the gate and runner.The flow of K213 superalloy during solidification is clarified in the article.The evolution process of the field and temperature field accurately predicts the occurrence of casting defectsposition and severity.Therefore, it is possible to provide K213 superalloy bladesThe design of precision casting process provides solid theoretical support,The design of precision casting technology has important reference significance.