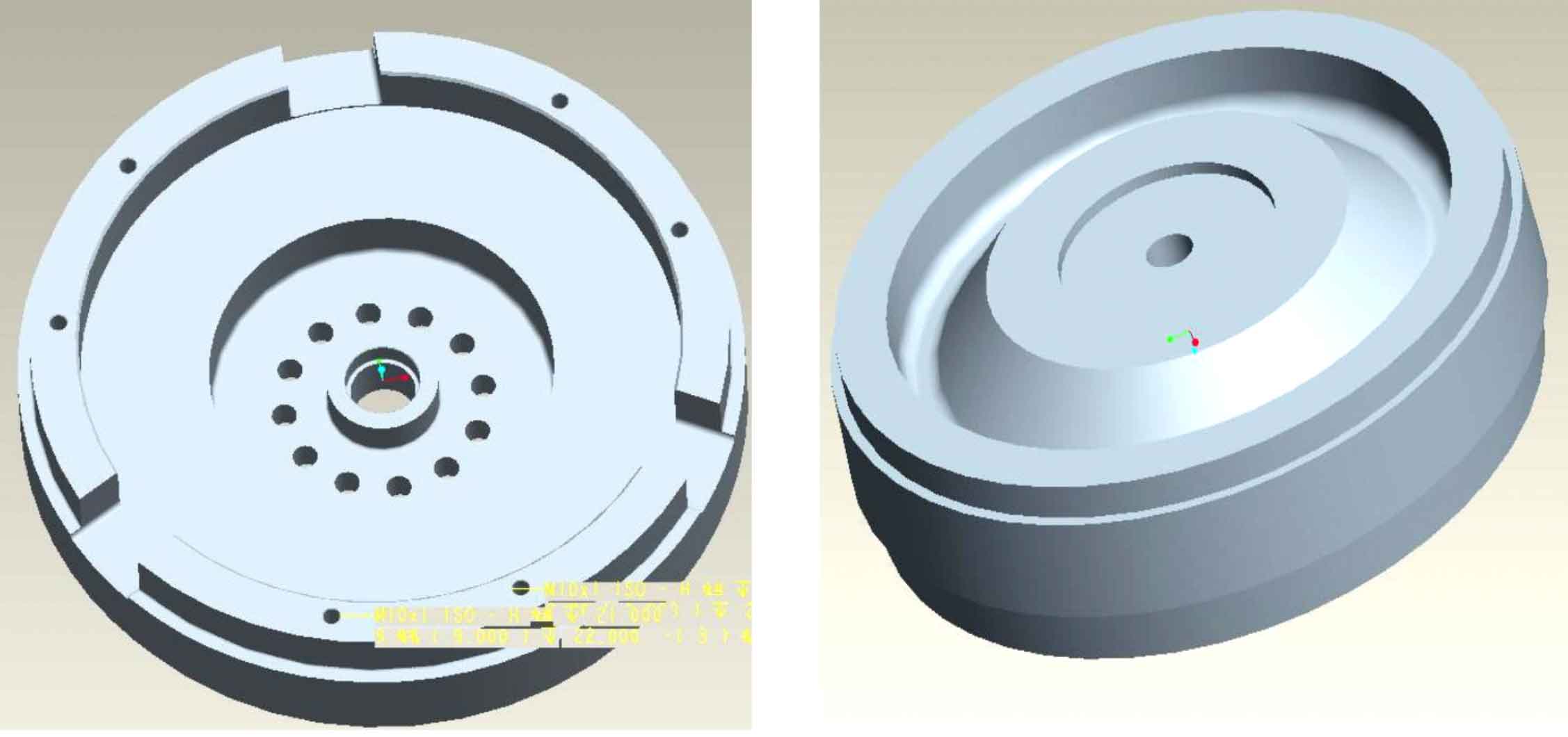

The flywheel is a product trial-produced by Shengrui Foundry for Tianjin Lovol Power Co., Ltd. The material grade of sand casting is QT450-10. It is required that the tensile strength of sand casting body should not be less than 450Mpa, the elongation should not be less than 10%, and the spheroidization rate should be more than 85%. The main problems in production are: internal defects of sand casting, serious shrinkage and porosity, which seriously affect the normal supply. The 3D drawing of parts and the gross damage of sand casting are as follows:

The material of the flywheel is QT450-10, and the weight of sand casting is 58 kg. Because it is relatively thick, it is difficult to form the middle hole with sand tire, so the middle lower core sand casting hole is adopted. The flywheel structure is relatively complex, and it is difficult to feed.

Flywheel process requirements: appearance requirements of sand casting: no crack is allowed, and the roughness of non-machined surface is not greater than Ra 12.5um; The processing table shall be free of pores, inclusions, slag holes and other sand casting defects.

Internal quality requirements of castings: 100% of sand castings shall be subject to X-ray flaw detection, and internal sand casting defects shall not exceed grade 4 according to ASTME155.95 atlas.