The simulation parameters of vertical pouring scheme are consistent with those of horizontal pouring scheme, and other material configuration parameters remain unchanged. After setting the parameters in ProCAST software, the simulation operation is carried out.

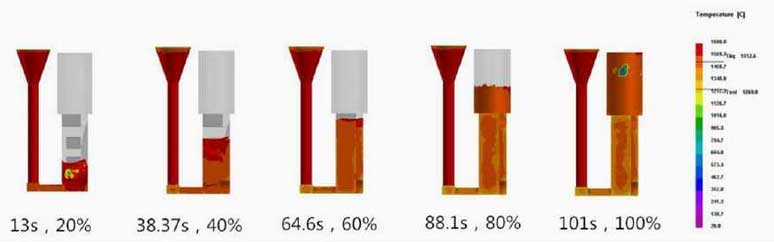

Figure 1 shows the filling situation of liquid metal at different times, and the red area is liquid metal.

It can be seen from Fig. 1 that after the molten steel enters the mold from the inner gate, the bottom is filled first, then the mold is filled vertically smoothly and rapidly, and finally injected into the riser. From the filling time interval, the time interval for each 20% filling is 13s, 25.37s, 26.23s, 23.5s and 12.9s respectively, showing a “fast slow fast” trend. Because the sprue is very long, the molten metal forms a high pressure head after filling the sprue, which makes the filling speed of molten metal in the runner and ingate very fast. When the molten metal enters the mold, the contact area between the metal liquid and the foam pattern expands rapidly, which is open to pour, and the filling speed is slowed down until the mold is filled. When the molten steel is soft into the riser, the theoretical pressure decreases and the filling speed increases slightly. The average pouring speed is 5kg / s. Although the pouring speed is slower than that of horizontal pouring, the filling process is relatively stable and there is no obvious turbulence phenomenon.

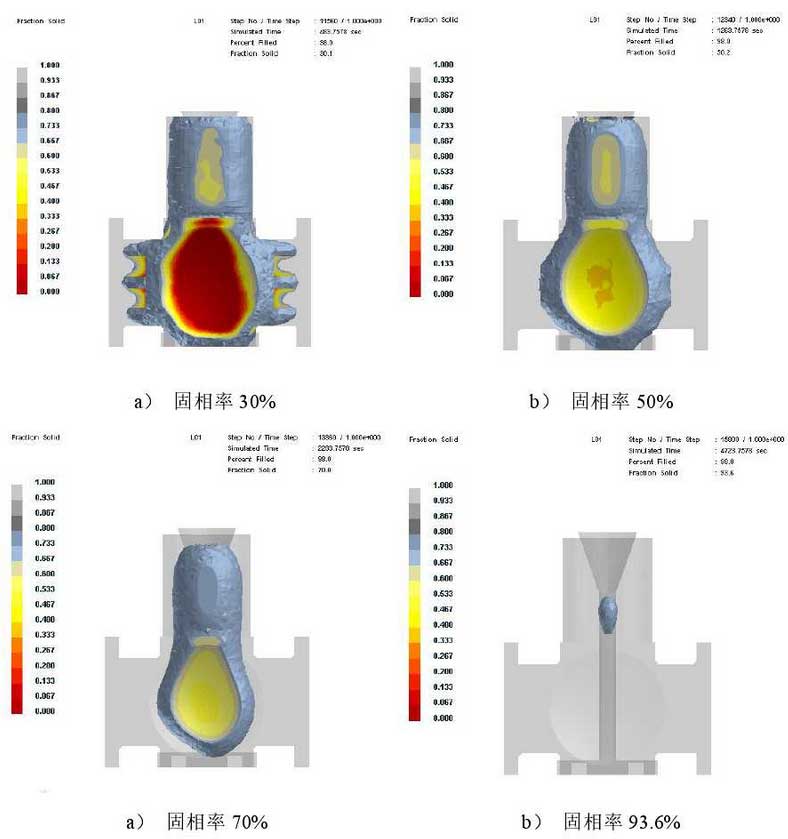

Figure 2 shows the distribution of fixed rate at different times.

It can be seen from Figure 2 that the liquid metal begins to solidify from the thin wall around the casting first, and finally at the center of the casting and the center of the riser, which basically conforms to the principle of sequential solidification. When the solidification ratio reaches 93.6%, all the liquid increasing areas are concentrated in the riser. During the whole solidification process, there is no isolated liquid increasing area in the casting, which indicates that the feeding condition of the casting is good.

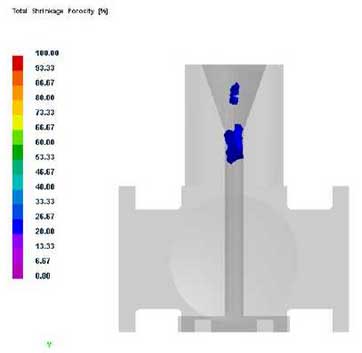

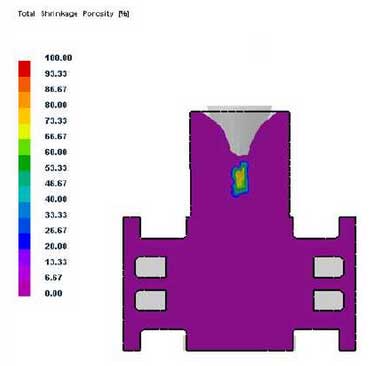

It can be seen from Fig. 3 and Fig. 4 that the distribution of shrinkage is consistent with that in Fig. 2 and Fig. 4.

The safety height of riser in Fig. 4 is measured by ProCAST software. The safety height of riser is about 9cm, which is much higher than the minimum safety height of 3cm. It shows that there is room for continuous optimization of riser height, and the process yield of castings can be further improved.

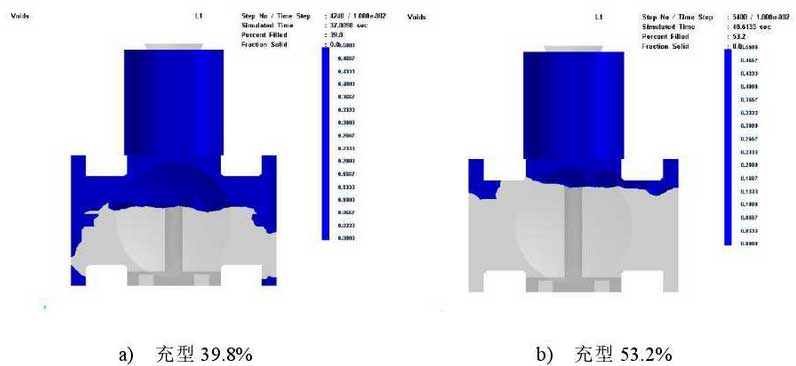

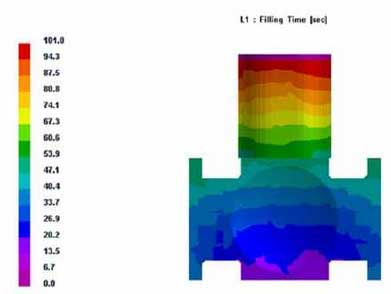

Fig. 5 shows the filling time cloud pattern. After pouring the metal liquid into the mold, it moves forward in a fan shape. The vertical rise speed of the center part of the casting is faster, but the sides of the casting are far away from the inner gate, the filling time is increased later, and the foam pyrolysis area appears in the late filling part. As shown in Fig. 6, the blue area indicates the foam appearance which has not yet been pyrolyzed. Although the isolated area of foam pyrolysis is small, the defects such as slag inclusion and porosity can easily occur. The riser at the top of the casting is the latest filling position, which is conducive to the realization of slag collection, exhaust and feeding functions of the riser, which is helpful to improve the casting quality.