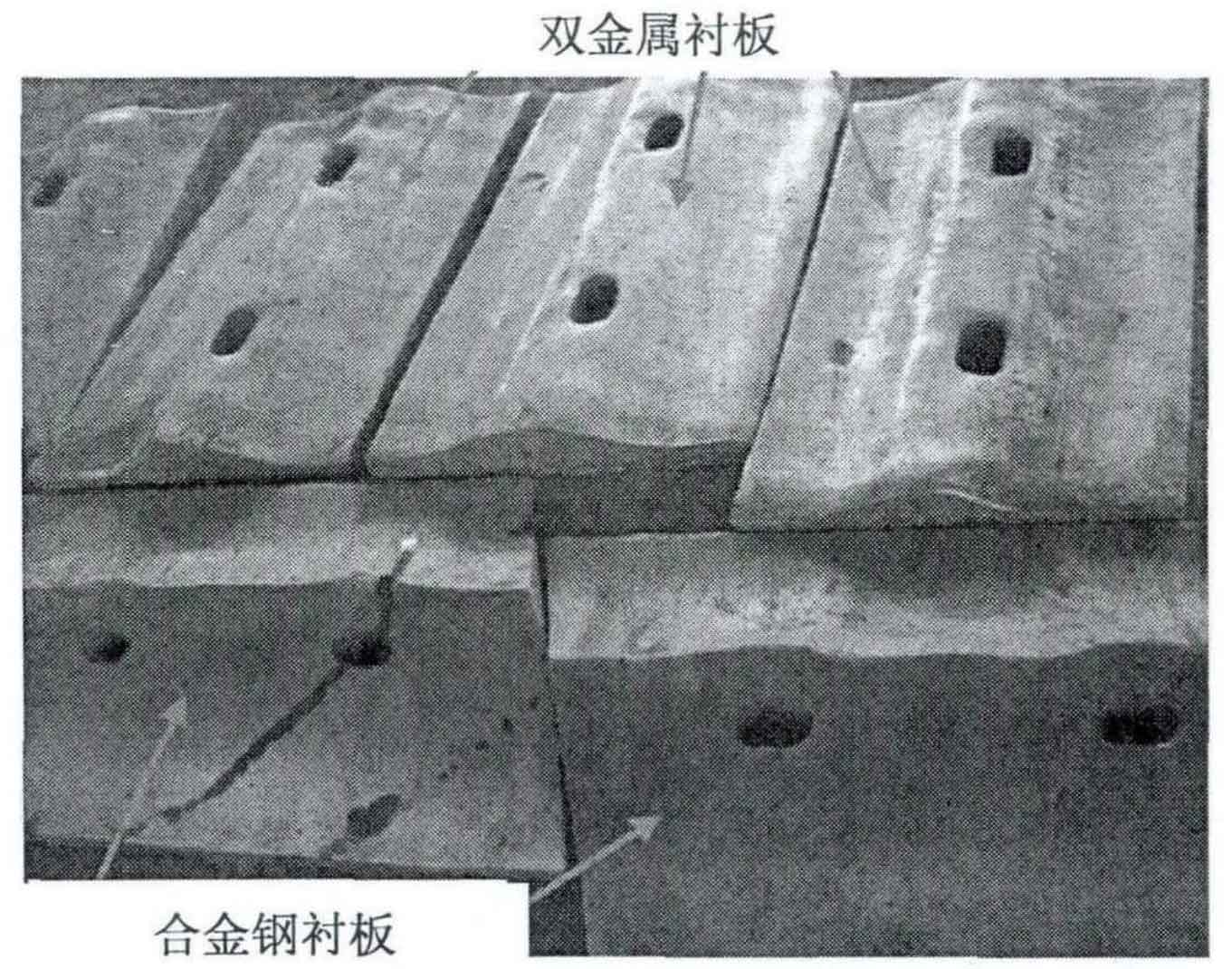

The ball mill has been running for six months under full load and full working conditions. As shown in the photo of preliminary opening inspection in Fig. 1, the service condition of high chromium cast iron carbon steel composite lining plate is obviously better than that of alloy steel lining plate: the latter is seriously worn, the surface is uneven, and there is a large area of oxidation, showing red color; The surface of the former is almost smooth and complete, showing silver and luster, but there are pits at a few local positions. This may be due to improper control of forming process conditions, resulting in casting defects or large iron chromium carbides. When the grinding ball impacts here, brittle fracture occurs.

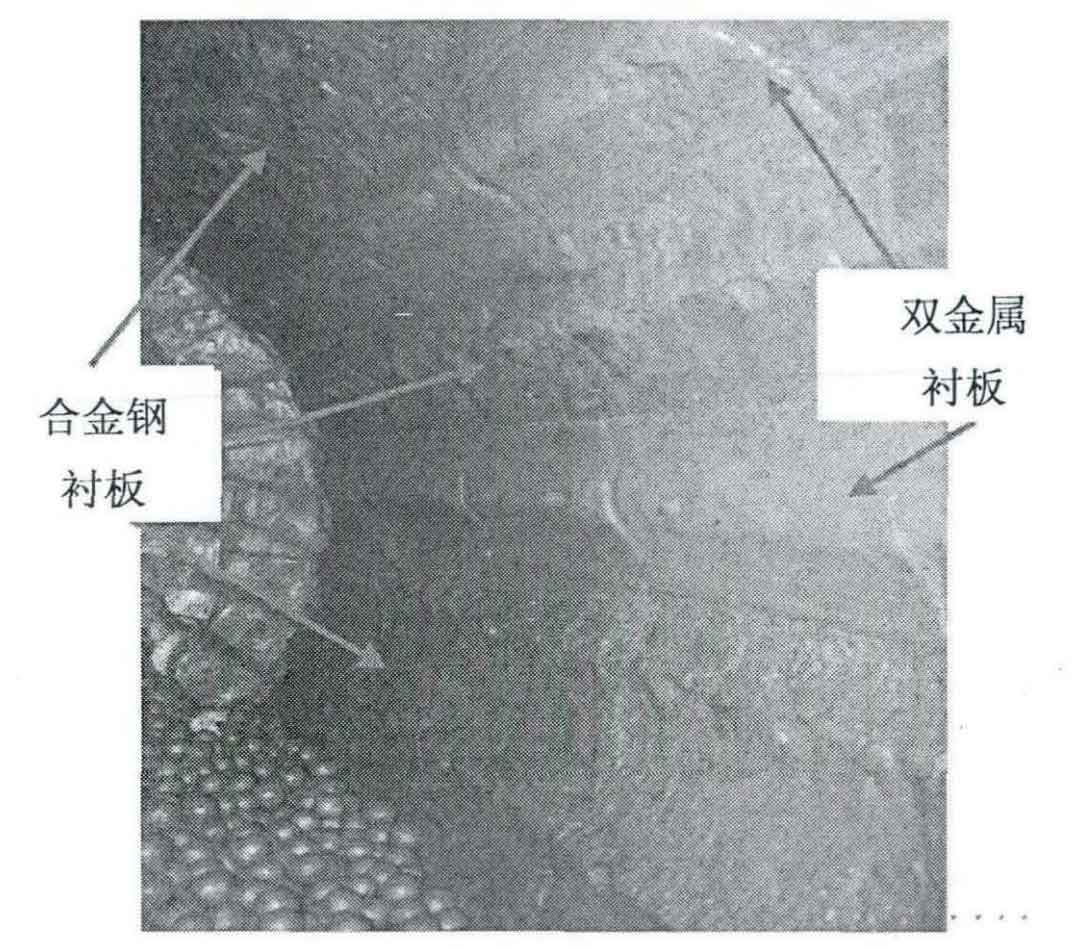

After the operator checked that the ball mill and its related parts were all normal, the cabin door was closed, and the full load operation continued for three months. The lining plate was disassembled from the ball mill for inspection. The comparison between the use of carbon steel high chromium cast iron composite lining plate and the original alloy steel is shown in Figure 2: the composite lining plate still retains the curved surface contour of smooth arc transition during installation, but the thickness is uniform and reduced appropriately, Silver and shiny; However, the original curved contour of the alloy steel lining plate has been completely changed, the minimum thickness has been reduced to about 10mm, and the whole lining plate has been completely oxidized and red rust color, meeting the conditions for scrapping and replacing the new lining plate.