1. Introduction

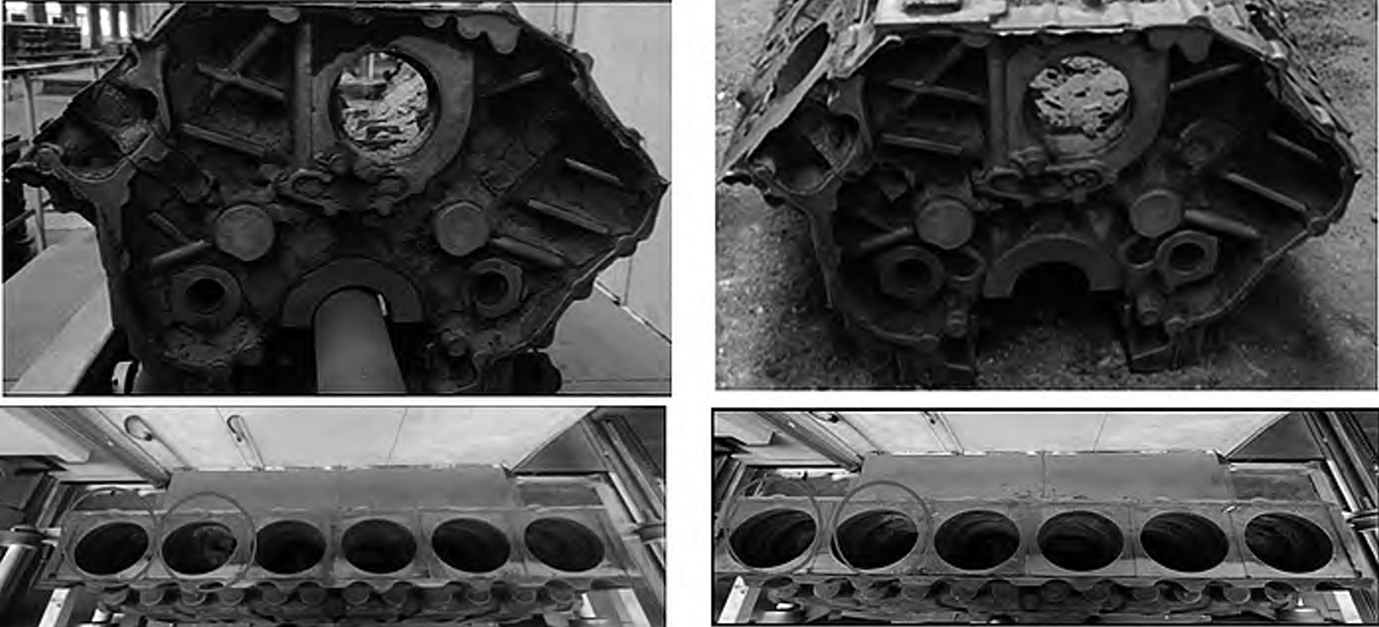

In the manufacturing industry, the casting process plays a crucial role in producing high – quality components. This paper focuses on a specific double – cylinder cylinder head, which is an important part of an engine. The cylinder head is produced by Chongqing New Red Flag Cylinder Head Manufacturing Co., LTD. It is designed for a 250 – displacement double – cylinder engine, with an A356 aluminum alloy material. The single – piece 毛坯 weight is 5 Kg, and its external dimensions are 244mm×228mm×114mm, with a minimum wall thickness of 3.5mm and a maximum thickness of 29mm (as shown in Figure 1).

| Parameter | Value |

|---|---|

| Engine Displacement | 250cc |

| Material | A356 Aluminum Alloy |

| Single – piece Weight | 5 Kg |

| External Dimensions | 244mm×228mm×114mm |

| Minimum Wall Thickness | 3.5mm |

| Maximum Thickness | 29mm |

The technical requirements for this cylinder head are extremely strict. There should be no cracks, pores, shrinkage porosity, looseness, slag inclusions, protrusions, cold shuts, or misruns that could affect its performance. The specific airtightness test requirements are detailed in Table 1.

| Test Item | Air Pressure | Pressurization Time | Balancing Time | Inspection Time | Allowable Leakage |

|---|---|---|---|---|---|

| Oil Duct Airtightness | 0.6MPa | 10s | 8s | 10s | ≤4ml/min |

| Water Jacket Airtightness | 0.4MPa | 4s | 5s | 2s | ≤5ml/min |

| Air Duct Airtightness | 0.2MPa | 5s | 4.5s | 2.5s | ≤7.5ml/min |

This product was developed for a Chongqing – based main – engine factory in 2016. Initially, the product qualification rate was far from satisfactory. Despite continuous optimization and improvement from 2016 to 2018, the comprehensive qualification rate was only 71.92%. Due to the low qualification rate, the customer placed no orders from 2019 to 2020, and the company even scrapped the product molds during the asset clearance and verification process. However, in the second half of 2021, the customer had a new demand for this product. In response, the company urgently restarted the design and manufacturing of the product molds. The casting team analyzed the previous issues and optimized the casting process, which led to a significant increase in the product’s comprehensive qualification rate to 91.78%.

2. Optimization Design and Application of the Product’s Casting Process

This cylinder head is a complex – shaped and structured component, composed of an integral water – way core, two intake and exhaust port cores, an oil chamber core, and a camshaft chamber core. The casting team carried out the following optimizations on the casting process:

2.1 Optimization and Comparison of the Pouring Process

The pouring process of this product was optimized mainly in the design of the riser shape. Additionally, the intake and exhaust sides were directly formed by metal molds. These optimizations shortened the solidification time of the casting, reduced the amount of sand cores used, improved production efficiency, and most importantly, enhanced the product’s comprehensive qualification rate.

2.2 Optimization of the Water – Way Sand Core Exhaust (Two Locations)

The water – way sand core and the oil – chamber sand core of this product were optimized to have a convex – concave fit. Moreover, the gas – discharge channel generated during the pouring of the water – way core in the oil – chamber core was connected to the exhaust channel in the riser, ensuring the smooth discharge of gases generated during the pouring process of the water – way sand core. In addition, the water – way core itself was evacuated by a negative – pressure pumping method.

| Optimization Measure | Optimization Before | Optimization After |

|---|---|---|

| Fit between Water – Way and Oil – Chamber Sand Cores | [Describe the previous fit, e.g., simple contact] | Convex – concave fit |

| Gas – Discharge Channel Connection | Disconnected or not well – connected | Connected between the oil – chamber core and the riser |

| Evacuation Method of Water – Way Core | No or ineffective evacuation | Negative – pressure pumping method |

2.3 Optimization and Comparison of the Metal Core for the Pre – Cast Hole of the Tensioner Hole

After optimization, the metal core for the pre – cast hole of the tensioner hole was made of beryllium bronze material, and the back of the metal core was cooled by air cooling. This completely solved the shrinkage porosity defect of the tensioner hole.

| Optimization Aspect | Optimization Before | Optimization After |

|---|---|---|

| Material of Metal Core | [Describe the original material] | Beryllium bronze |

| Cooling Method of Metal Core | [Describe the previous cooling method] | Air – cooled |

| Shrinkage Porosity Defect of Tensioner Hole | Present | Eliminated |

3. Conclusion

Through the optimization and improvement of the above – mentioned processes and the remanufacturing of the molds, the comprehensive qualification rate of this product has increased significantly from 71.92% to 91.78%. This case shows that the optimization of the casting process should be carried out throughout the entire casting process. When the qualification rate of certain products is too low, exploring breakthroughs from the perspective of casting process optimization can be an effective solution.

In the future, with the continuous development of manufacturing technology, more advanced casting process optimization methods may emerge. For example, the application of simulation technology can more accurately predict the solidification process and defect generation during casting, providing more scientific basis for process optimization. Additionally, the development of new materials and new manufacturing equipment will also bring new opportunities for improving the quality and qualification rate of castings.

| Future Development Direction | Potential Impact |

|---|---|

| Application of Simulation Technology | More accurate prediction of solidification and defect generation, guiding more scientific process optimization |

| Development of New Materials | Improve the performance of castings, reduce defects, and increase qualification rate |

| Development of New Manufacturing Equipment | Improve production efficiency and casting quality |

Manufacturers should keep an eye on these technological trends and continuously optimize their casting processes to meet the increasingly high – quality requirements of products in the market. This not only helps to improve the competitiveness of enterprises but also promotes the overall development of the casting industry.