The semi-closed and semi-open gating system is adopted, and the sectional area ratio of the runner at each position is: Σ S straight: Σ S horizontal: Σ In S=1 ∶ 1.15 ∶ 1.3, the flow limit is set at the overlap position of the arc section of the transverse runner to reduce the flow rate of molten iron entering the mold cavity; Use two pieces of 90 mm × 90 mm × 1.5 mm fiber filter screen, 2 liquid inlets are designed, and a riser is set at the liquid inlet. The riser is checked according to the volume method, and the size of the feeding riser is increased to ϕ 80 mm, and adjust the position of the runner to the vicinity of hot spots 2 and 3 to ensure that the position can be effectively supplemented; Add a riser above the boss hot spot 1. The specification of the riser position is ϕ 60 mm × 90 mm hot riser to improve the feeding efficiency of the riser.

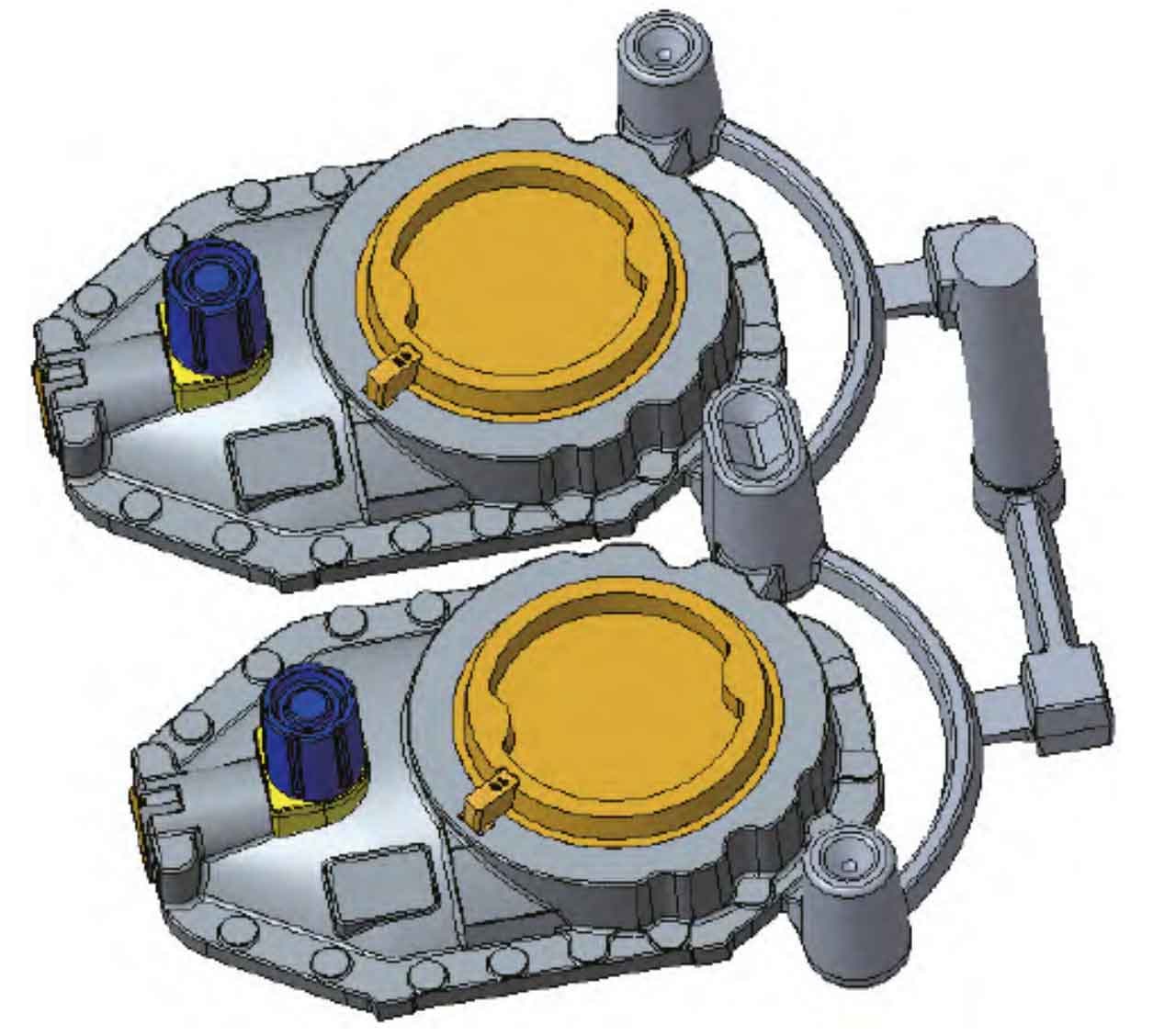

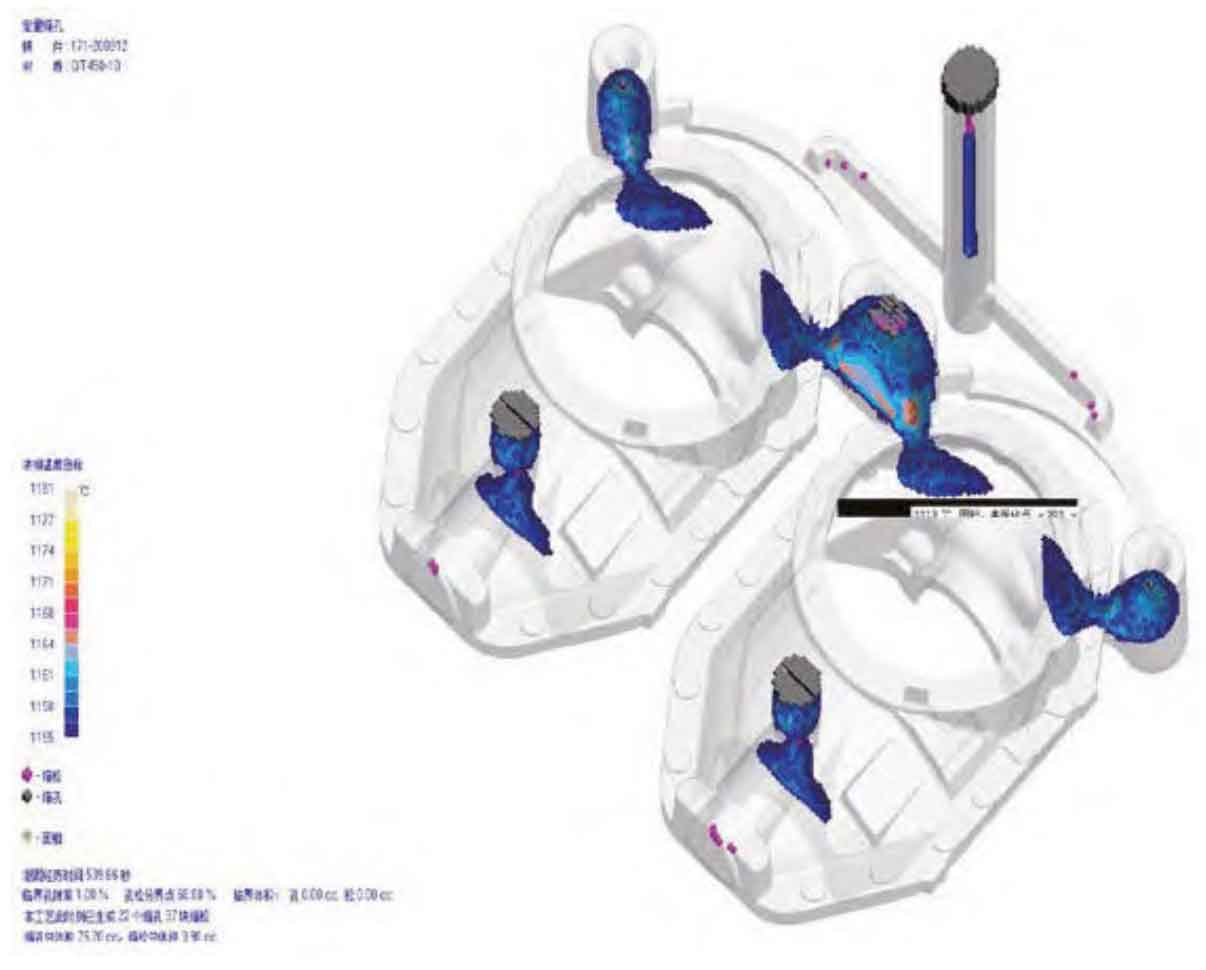

The casting process of reducer housing after optimization design is shown in Figure 1, and the simulation results after optimization are shown in Figure 2.

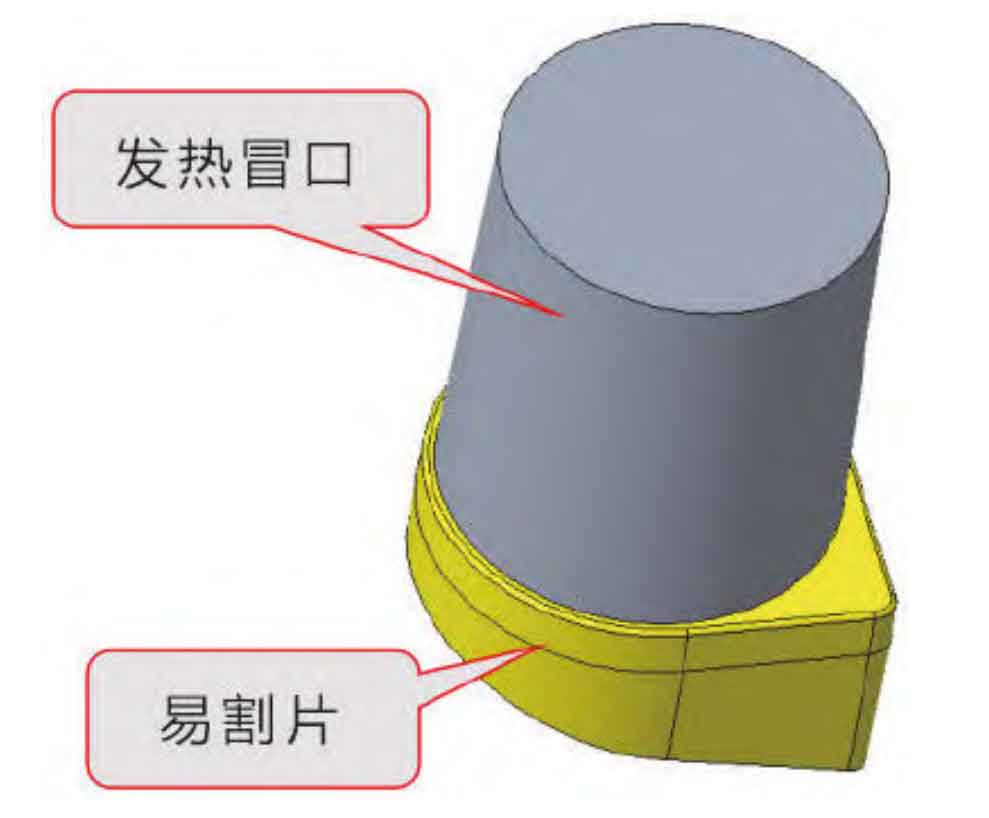

In order to solve the problem that the heating riser and the easy-to-cut sand core fall off from the upper mold when they are lowered, the heating riser and the easy-to-cut sand core shall be bonded in advance, as shown in Figure 3; In addition, a groove is added at the side of the heating riser mold to form an interference point after core-making, as shown in Figure 4. When lowering the core, press the heating riser assembly into the upper mold with a tool to ensure that the heating riser assembly does not fall off after lowering the core.

From September to November 2020, the author completed the verification of the new process. After several rounds of verification, the casting anatomy of the reducer housing did not find any shrinkage cavity and porosity casting defects at the positions 1, 2 and 3 of the hot spot. The anatomical results are shown in Figure 5. From October to December, the batch production, processing and verification of 6031 pieces showed that no shrinkage cavity and shrinkage porosity casting defects were found in the products. See the table for the statistics of defect types of waste products.

| Mouth | Processing quantity/piece | Scrap quantity/piece | Reject rate (%) | Sand hole waste/piece | Size deviation scrap/piece | Industrial waste/piece | Other scrap/piece |

| September | 65 | 7 | 10.77 | 1 | 4 | 2 | — |

| October | 1 250 | 15 | 1.20 | 8 | 3 | 3 | 1 |

| November | 2 180 | 18 | 0.83 | 10 | 2 | 4 | 2 |

| December | 2 536 | 19 | 0.75 | 12 | 3 | 2 | 2 |

| Total | 6 031 | 59 | 0.98 | 31 | 12 | 11 | 5 |