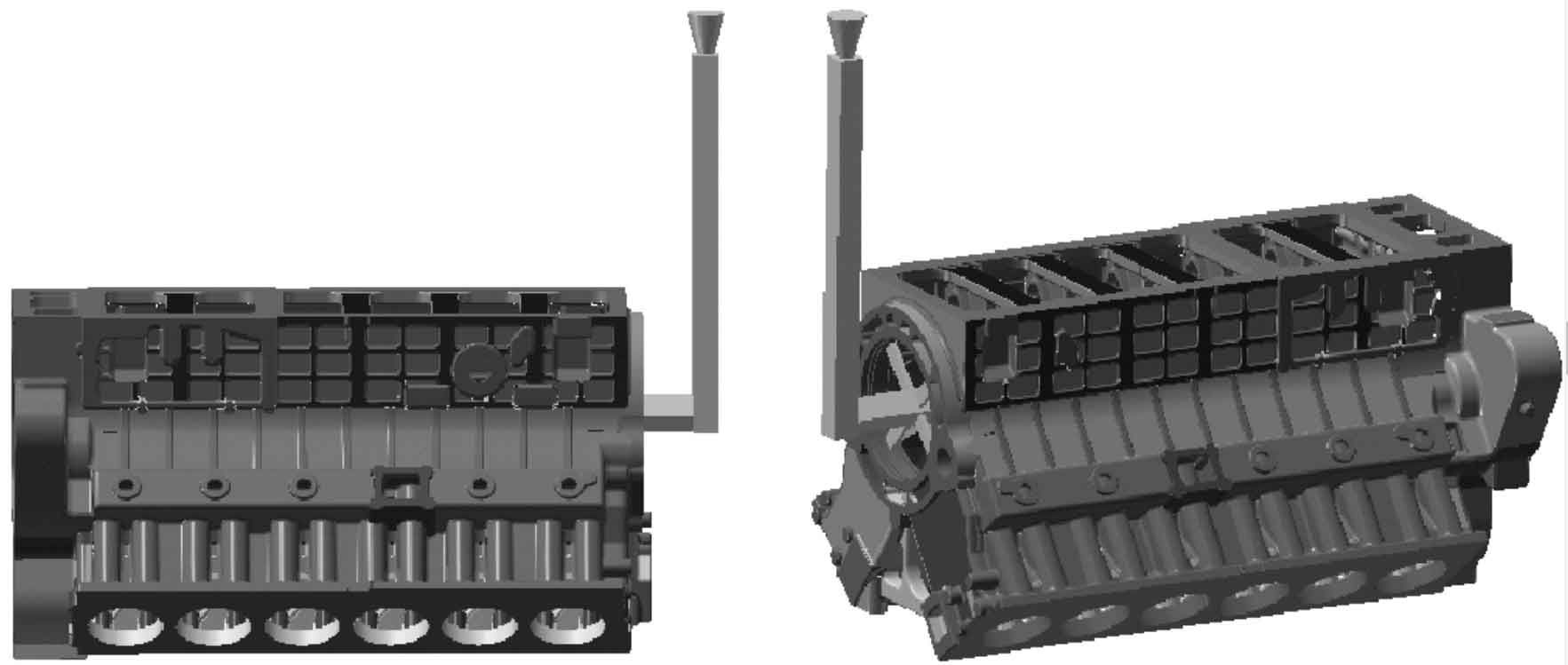

Change the pouring position of the cylinder block and place the top surface of the lost foam casting of the cylinder block at the bottom, as shown in Figure 1. The middle injection pouring is adopted, and the pouring system remains unchanged.

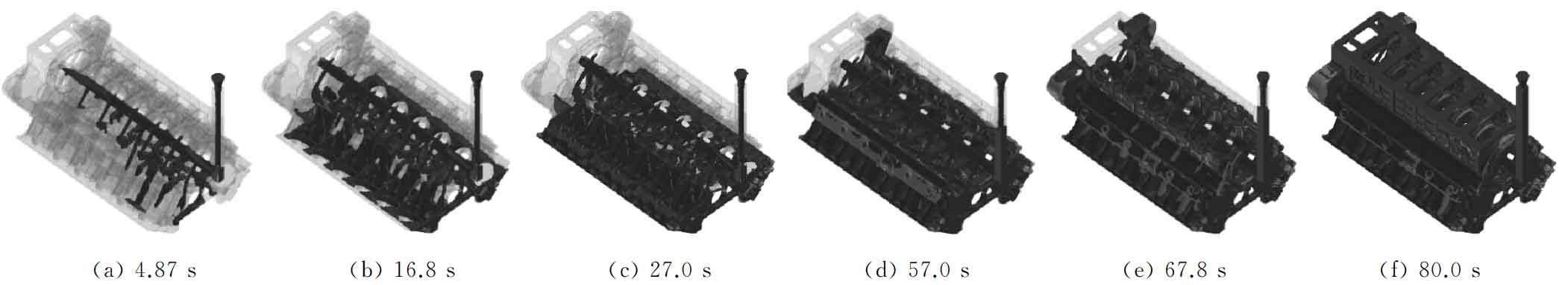

1. Mold filling process

The filling process of changing the pouring position of the cylinder block is shown in Figure 2. When t = 4.87s, the molten metal begins to flow from the inner sprue into the bottom of the lost foam casting of the cylinder block, and the mold filling is stable, as shown in Fig. 2A; When t = 16.8s, the mold filling at the bottom of the lost foam casting of the cylinder block is completed, as shown in Fig. 2B; When t = 27.0s, the liquid metal in the mold cavity rises and begins to fill both sides of the lost foam casting of the cylinder block, as shown in Fig. 2C; When t = 57.0s, the mold filling on both sides of the lost foam casting of the cylinder block is completed, the liquid metal rises slowly, and the mold filling of the end cover of the lost foam casting of the cylinder block is started, as shown in Fig. 2D; When t = 67.8s, the filling of the lost foam casting of the cylinder block is about to be completed, and the bottom of the lost foam casting of the cylinder block begins to solidify, as shown in Fig. 2E; When t = 80.0s, the filling of lost foam casting of cylinder block is completed, as shown in Fig. 2F. In the whole filling process, the liquid metal flows smoothly, starts filling from the bottom, rises slowly, and there is no splash.

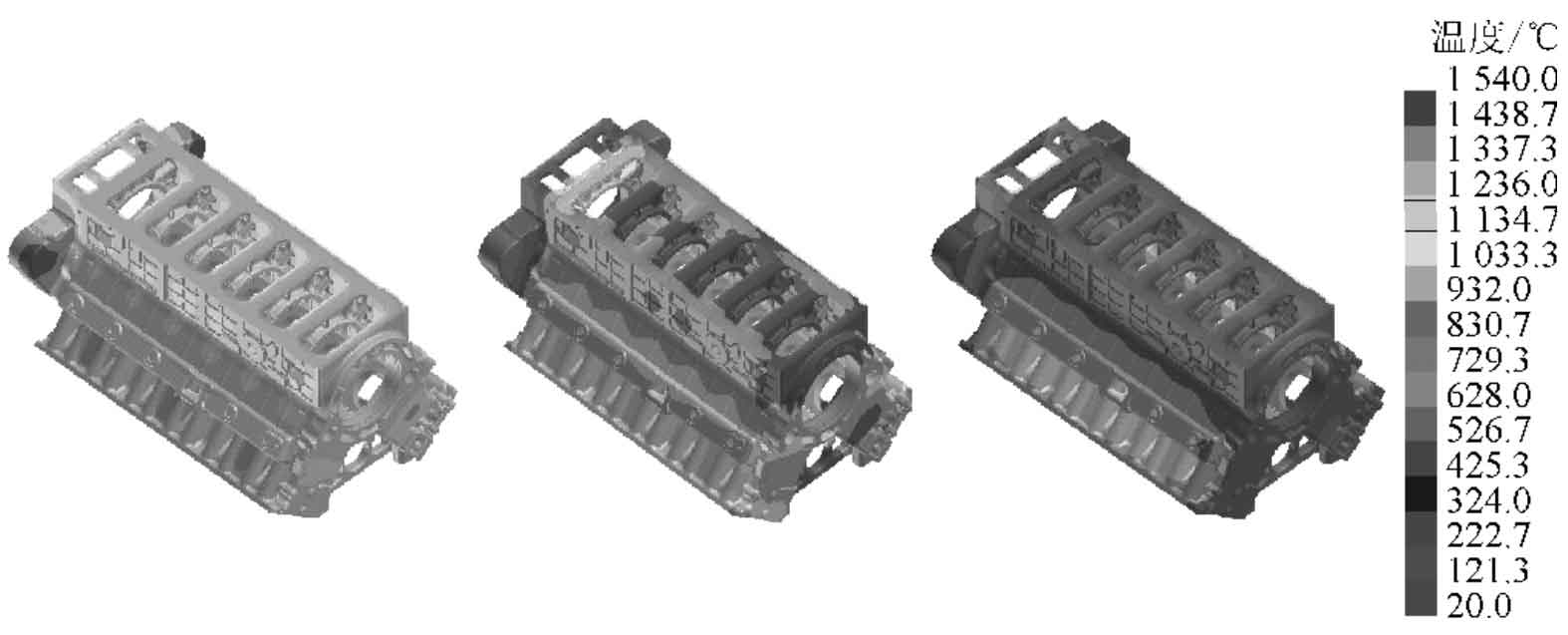

2. Analysis of solidification process

Fig. 3 is a schematic diagram of the solidification process of changing the pouring position of the cylinder block. It can be seen that the lost foam casting of the cylinder block solidifies first at the end cover with thin wall. The lost foam casting of the cylinder block solidifies faster at the top and slower at both sides. When the lost foam casting of the cylinder block solidifies completely, the temperature on both sides of the V-shape at the place with large wall thickness is higher, which is easy to produce hot joints, shrinkage porosity, shrinkage and other defects.