1. Introduction

In the electrolytic aluminum production industry, the anode steel claw plays a crucial role. It is a key component of the pre – baked anode electrolytic cell, responsible for gripping the anode carbon block and transmitting a large – scale direct – current. The quality of the anode steel claw, especially its density and conductivity, has a significant impact on the production efficiency and economic benefits of electrolytic aluminum.

The current situation of anode steel claw production in China is not optimistic. Many electrolytic aluminum enterprises consider anode steel claws as low – end castings, resulting in low – quality products. The use of poor – quality raw materials such as scrap steel, miscellaneous steel, and recycled steel claws leads to large fluctuations in alloy element content. High levels of impurity elements like \(C\geq0.5\%\), \(S\geq0.05\%\), and \(P\geq0.05\%\) increase the resistance of the steel claws. Moreover, the existing casting processes often have problems, causing internal defects such as shrinkage cavities, porosity, and inclusions, which further reduce the effective conductive area and increase the resistivity.

The lost foam casting process has unique advantages, such as high – precision casting, less casting defects, and good surface quality. Therefore, optimizing the lost foam casting process for anode steel claws is of great significance for improving the quality of anode steel claws, reducing production costs, and enhancing the competitiveness of the electrolytic aluminum industry.

2. Chemical Composition and Mechanical Properties Requirements of Anode Steel Claw

2.1 Influence of Chemical Composition on Resistivity

The alloy composition in anode steel claws has a direct impact on their resistivity. Table 1 shows the resistivity differences of anode steel claws made from different raw materials.

| Raw Materials | Resistivity (\(\mu\Omega\cdot m\)) |

|---|---|

| Anode steel claws made from high – quality scrap steel | 0.2 – 0.5 |

| Anode steel claws made from waste raw materials mixed with pig iron | Over 0.8 |

| Pure iron | Approximately 0.1 |

Pure iron has a low resistivity but low strength. When using scrap steel, the resistivity can be within a certain range. However, when mixed with pig iron, the resistivity increases significantly. Considering both resistivity and strength requirements, a low – carbon alloy steel composition is selected for anode steel claws.

2.2 Optimized Chemical Composition

The optimized chemical composition of the anode steel claw is shown in Table 2.

| Element | Composition Range (Mass Fraction, %) |

|---|---|

| C | 0.17 – 0.23 |

| Si | ≤ 0.6 |

| Mn | 1.00 – 1.16 |

| S | ≤ 0.02 |

| P | ≤ 0.02 |

| Ni | ≤ 0.8 |

This composition range can ensure that the anode steel claw has relatively low resistivity while meeting the strength requirements.

2.3 Mechanical Properties Requirements

In addition to chemical composition, the anode steel claw also has specific mechanical properties requirements. Table 3 shows the mechanical properties that the anode steel claw needs to meet.

| Product Name | Material | Heat Treatment | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Notch Impact Absorption Energy (J) |

|---|---|---|---|---|---|---|

| Anode Steel Claw | Low – Carbon Alloy Steel | Normalizing | 500 – 650 | ≥ 300 | ≥ 22 | ≥ 55 |

These mechanical properties ensure that the anode steel claw can work stably under the harsh conditions of electrolytic aluminum production.

3. Experimental Part

3.1 Selection of Test Piece and Mold Design

3.1.1 Test Piece Selection

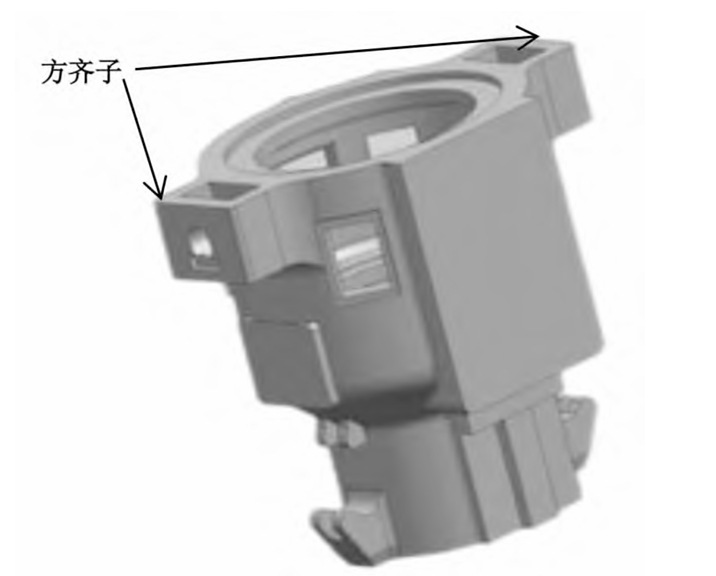

The three – claw anode steel claw is selected as the test piece. Figure 1 shows the appearance of the three – claw anode steel claw. Its important dimensions are as follows: length 980 mm, height 400 mm, cylinder diameter 180 mm, cylinder height 250 mm, beam width 100 mm, beam height 150 mm. The center – to – center distance between adjacent cylinders is \(400\ mm\pm1\ mm\), and the straightness deviation of the three cylinders is less than 1 mm. Each finished product needs to pass the gauge inspection.

[Insert a picture of the three – claw anode steel claw here]

3.1.2 Mold Design

The mold uses a machined white mold, which is split in the middle. Two pieces form an anode steel claw. The white mold is hollow as a whole to reduce the gas evolution during the casting process and carbon defects in the casting. Reinforcing ribs are designed inside to control the deformation of the cylindrical white mold. A tie – bar is designed between the middle claw – head cylinder and the two – side claw – head cylinders as the inner runner, which can also prevent the casting from shrinking and deforming.

3.2 Process Design and Trial – Production Results

3.2.1 First Process Design and Results

The anode steel claw generally prefers the top – pouring casting process. The advantages of top – pouring are fast pouring speed, easy filling, and effective prevention of cold – shut and misrun defects, as well as a high process yield.

In this design, the anode steel claw is cast with the claw – head facing down and the beam on top. A DN225 mm straight – tube exothermic riser is opened on the beam as the pouring and riser. The solidification simulation results using PorCast software are shown in Figure 2. Due to the thin beam of the anode steel claw and the far – away position of the riser from the two – end claw – heads, effective feeding cannot be carried out, resulting in shrinkage cavities inside the two – end claw – heads, which cannot meet the flaw – detection requirements.

3.2.2 Second Process Design and Results

According to the first simulation results, the design is improved. The anode steel claw is cast with the claw – head facing up and the beam on the bottom. A cylindrical foam riser with a diameter of 230 mm and a height of 300 mm is placed on each claw – head. The inner runner is opened on the claw – head, and the horizontal runner is placed on the upper part of the tie – bar. Two pieces are cast in one group. The vacuum negative pressure is – 0.06 – – 0.04 MPa, and the pouring temperature is 1580 – 1600 °C. The pouring system is shown in Figure 3.

The pouring test results are as follows: The ultrasonic flaw – detection results show that for No. 1 casting, shrinkage cavity defects are found when processing the two – side risers. There is no bottom wave in the area with a diameter of about 40 mm on both sides of the cylinder, and obvious defects exist in the 50 – 100 mm depth area of the middle cylinder. For No. 2 casting, a shrinkage cavity appears after processing one – side riser. There is no bottom wave in the area with a diameter of 70 mm on one side, no bottom wave in the area with a diameter of 30 – 35 mm on the other side, and defects exist in the 50 – 100 mm depth area of the middle cylinder, as shown in Figure 4.

The reason for the defects is that the foam white mold loses its shape while being poured under negative pressure. The molten metal is affected by the super – cooling caused by the suction during the filling process. Although feeding risers are installed, they cannot play their due feeding role. Only when the riser molten steel solidifies last can the feeding effect of the riser be fully exerted.

3.2.3 Third Process Design and Results

Based on the test results, the process is further improved. The anode steel claw is still cast with the claw – head facing up and the beam on the bottom. The original risers on each claw – head are changed to exothermic risers. The middle column uses a DN225 mm exothermic riser, and the two – side columns use DN200 mm exothermic risers. The inner runner is opened on the claw – head cylinder, and the horizontal runner is placed on the upper part of the tie – bar. Two pieces are cast in one group, as shown in Figure 5.

The pouring test results show that after cutting the riser, about 10% of the castings have gas – shrinkage cavities at the root of the cylinder riser on the side far from the pouring cup. The gas – shrinkage cavity defects are significantly more when pouring in rainy weather.

The reasons for the generation of gas holes are as follows: (1) The white mold or the yellow mold after painting the coating is not completely dried. Water vapor forms gas holes at high temperatures during the casting process. (2) Gas holes are generated due to poor deoxidation during casting. (3) The design of the casting system is unreasonable, and the gas entrained by the molten steel during casting cannot be discharged in time, forming gas holes. (4) The pouring speed is too slow. When the molten steel reaches the riser, it is in a semi – solid state, and the gas cannot float up and be discharged outside the casting.

3.2.4 Fourth Process Design and Results

According to the third – test results, the process is improved as follows: (1) Prolong the drying time of the white mold and yellow mold. (2) When it is rainy, add 0.15% zirconium – iron for enhanced deoxidation when the molten steel is poured from the ladle to 1/3 – 1/2. (3) Keep the other parts of the casting system unchanged, adjust the horizontal runner to the lower part of the tie – bar, increase the pouring cup, and increase the pouring speed to ensure that the horizontal runner is full during the casting process and prevent gas entrainment. (4) Increase the pouring temperature to 1600 – 1620 °C for casting. The casting system and the casting are shown in Figure 6.

The pouring test results show that among the subsequent 500 cast anode steel claws, the scrap rate caused by gas holes is less than 2%, which is a relatively stable process. After cutting the riser, the surface has no defects, the flaw – detection shows no shrinkage cavities, and the cut – open internal structure is dense without defects.

3.2.5 Fifth Process Design and Results

In order to improve the process yield, an attempt is made to abandon the complex horizontal runner and directly pour from the middle exothermic riser. The process changes from casting two pieces in one pour to casting one piece in one pour. The sand – burying process and test results are shown in Figure 7.

The test results and analysis show that after cutting the riser, there are no shrinkage cavities or gas holes at the root of the middle riser, but obvious gas holes are generated at the roots of the two – side risers. The reason is that the molten steel in the two – side risers mainly comes from the bottom of the middle cylinder. The hot molten steel does not flow through the middle tie – bar, so the temperature of the molten steel in the two – side risers is relatively low, and the gas in the molten steel cannot float up effectively, resulting in gas holes.

4. Conclusion

After several rounds of experimental verification, the fourth improved process design scheme is adopted for mass production of anode steel claws. That is, the two – side cylinders use DN200 mm exothermic risers, the middle cylinder uses a DN225 mm exothermic riser, and the horizontal runner is placed at the bottom of the inner runner in the casting system. This process can produce high – density and defect – free anode steel claw castings.

Compared with the currently used steel claw materials, the resistivity of the anode steel claws produced by this process can be reduced by about 30% in the working temperature range of the anode steel claws, resulting in significant power – saving effects. This has been recognized by users and has generated great economic and social benefits. At the same time, it will surely promote the technological progress of China’s electrolytic aluminum industry.

In future research, more attention can be paid to the influence of different alloying elements on the performance of anode steel claws, and further optimization of the casting process parameters can be carried out to continuously improve the quality of anode steel claws and meet the growing needs of the electrolytic aluminum industry.