The coupler knuckle is connected with the coupler body through the coupler knuckle pin. During the operation of the vehicle body, the coupler knuckle pin hole is seriously worn, and the sand casting quality around the pin hole is required to be high; The inner wrist surface of the coupler tongue and the pressure push table are the main bearing parts, and the cracks and wear in the actual operation are also mainly caused by this. In order to simplify the process and improve the quality of sand castings, the following process improvement scheme is proposed:

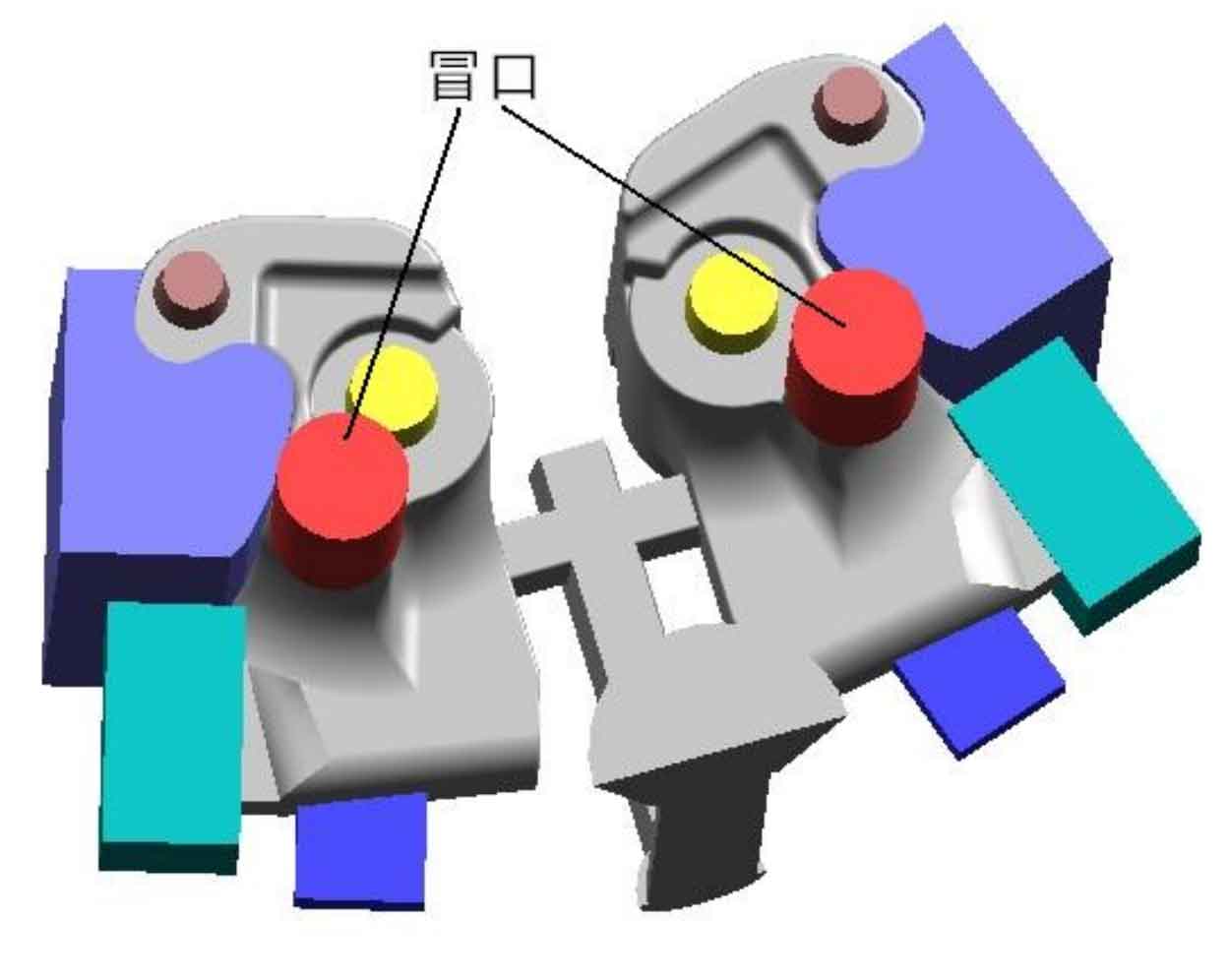

(1) The sand casting process is changed to four pieces in a box, symmetrical structure, two pieces in a group, flat pouring;

(2) Change the introduction position of the inner gate of sand casting and place it between the pin hole on the back of the hook tongue and the hook tongue to avoid the impact of liquid steel on the sand core and sand mold at the pin hole and the defects of sand flushing and slag inclusion;

(3) The form of placing a large riser between the transverse sprue and the inner sprue is not adopted, and the insulating top concealed riser is placed separately at the feeding position of each sand casting. Because the wall thickness of the inner wrist surface of the hook tongue and the arc part of the guard pin flange close to the outer side of the hook wrist is large and is the main stress part, it is not suitable to place the cold iron (easy to crack), so the riser position is above the upper compression push table, and the module method is used to design and calculate the riser size. The improved sand casting process diagram of hook tongue is shown in the figure.