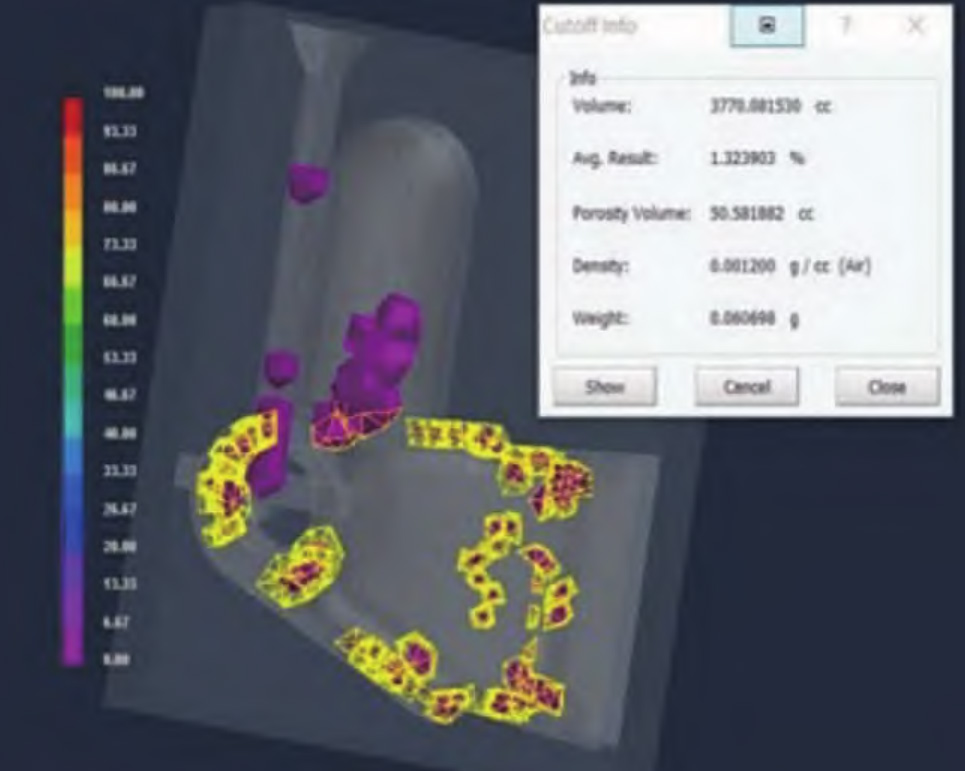

Due to the occurrence of insufficient pouring defects above the cylindrical part of the sand casting shell in Plan 1 and Plan 2, through analysis of Figure 1 and Figure 2, Plan 1 and Plan 2 also have more porosity defects, and there is also shrinkage porosity at the base in actual production. Therefore, a third plan (see Figure 3) was designed, and the position of the inner gate was adjusted. Four open risers were designed, with two of them having a diameter of 110mm, The height is 350mm. The other two exposed risers are stepped in shape, with a lower diameter of 200mm and a height of 32.5mm, and an upper diameter of 135mm and a height of 330mm.

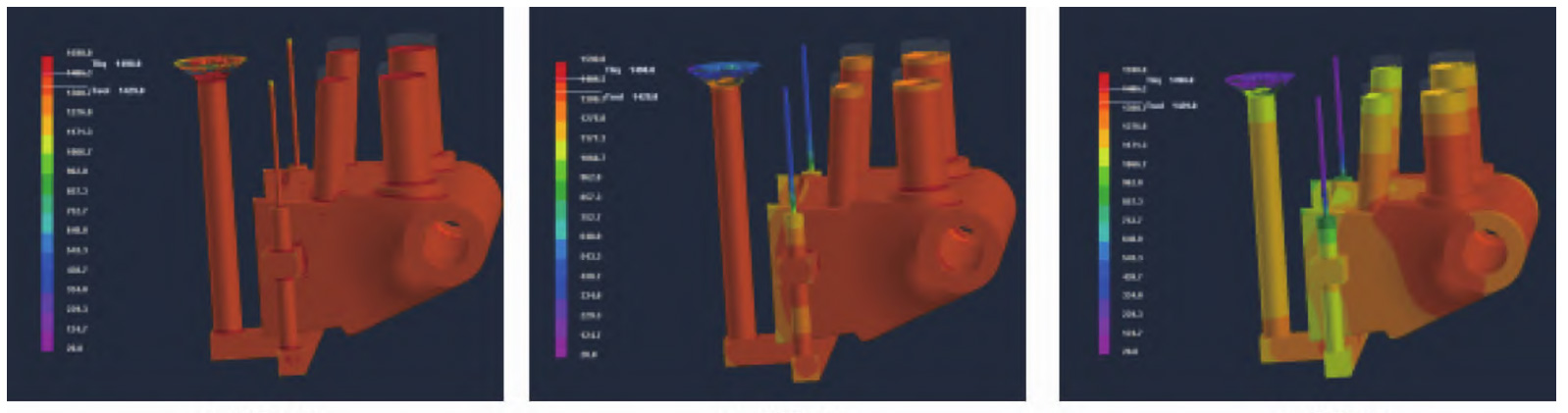

The filling process of the third process scheme is shown in Figure 4. When the metal liquid enters the mold cavity, it fills the lower part of the inner gate and the right side of the inner gate simultaneously, and then fills from bottom to top. The filling process is from bottom to top, which is conducive to the discharge of gas in the mold cavity and reduces the formation of pores in sand castings. From the perspective of temperature distribution during mold filling process, the temperature of sand casting base is basically low and the temperature of cylindrical part is high during the whole mold filling process. When the initial pouring temperature is 1560 ℃, the minimum temperature at the end of mold filling is about 1100 ℃. From the temperature field during the filling process, it can be seen that the temperature of the molten metal at the inner runner is slightly higher. In the early stage of pouring, the temperature of the molten metal decreases relatively quickly, but as pouring continues, the rate of temperature decrease of the molten metal decreases and is basically in a stable stage. In the early stage of pouring, the heat loss of molten metal is relatively severe, while as the pouring time increases, the heat loss is relatively small.

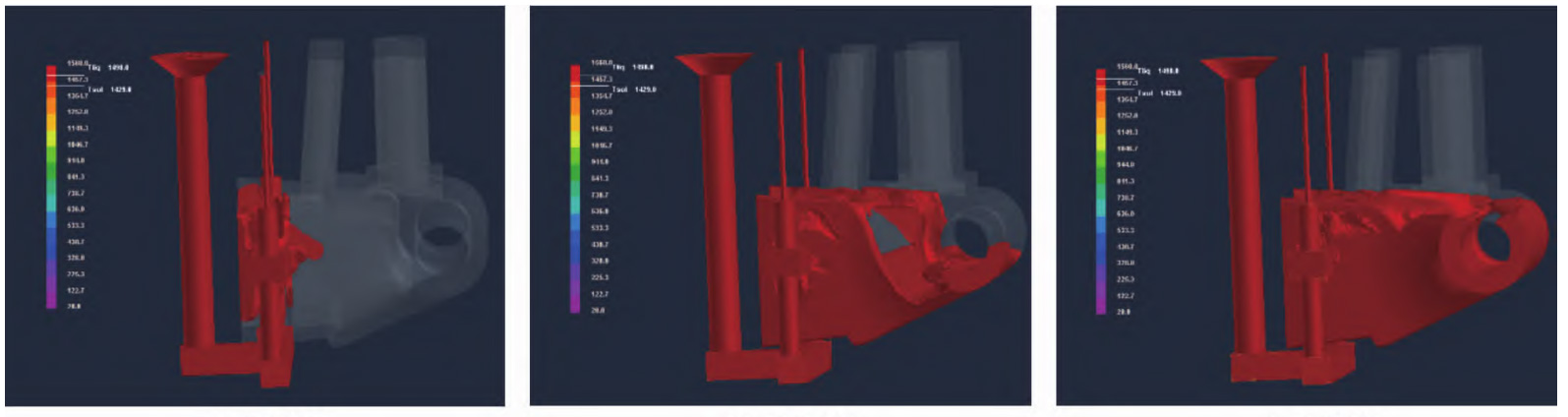

The solidification process of molten metal is shown in Figure 5. Overall, the complete solidification time of sand castings is relatively long, and the solidification speed is much slower than that of mold filling. The temperature distribution of sand casting during the whole solidification process basically increases gradually from the base to the cylindrical part. The temperature of the base part is lower, and it solidifies first, while the temperature of the cylindrical part is higher, that is, the thin wall of the sand casting solidifies first, and the part with larger wall thickness solidifies later. A riser is set at the part with later solidification to strengthen feeding. After solidification, the sand casting has no defects, which proves that this process is reasonable.