1. Orthogonal experimental design

In sand mold casting, pouring temperature and pouring speed are two important parameters in the sand mold casting process. In order to obtain a more reasonable pouring temperature and pouring speed, orthogonal tests were conducted based on the third process plan. The designed virtual orthogonal test factor level table is shown in Table 1.

| Horizontal | Pouring temperature/℃ | Pouring speed/(m · s ^ – 1) |

| 1 | 1530 | 1.3 |

| 2 | 1560 | 1.6 |

| 3 | 1590 | 1.9 |

2. Range Analysis

The range analysis results of this test are shown in Table 2.

| Group Number | Pouring temperature/℃ | Pouring speed/(m · s ^ – 1) | Pore volume/cm ^ 3 |

| 1 | 1530 | 1.3 | 2.368 |

| 2 | 1530 | 1.6 | 2.201 |

| 3 | 1530 | 1.9 | 2.503 |

| 4 | 1560 | 1.3 | 1.553 |

| 5 | 1560 | 1.6 | 1.416 |

| 6 | 1560 | 1.9 | 1.818 |

| 7 | 1590 | 1.3 | 1.984 |

| 8 | 1590 | 1.6 | 2.066 |

| 9 | 1590 | 1.9 | 2.206 |

From Table 2, it can be seen that the range of various factors on defect pore volume is 2.290 for pouring temperature, which is greater than 0.844 for pouring speed, indicating that pouring temperature has a significant impact on pore volume; With the increase of pouring temperature, the pore volume first decreases and then increases, while with the increase of pouring speed, the pore volume first decreases and then increases.

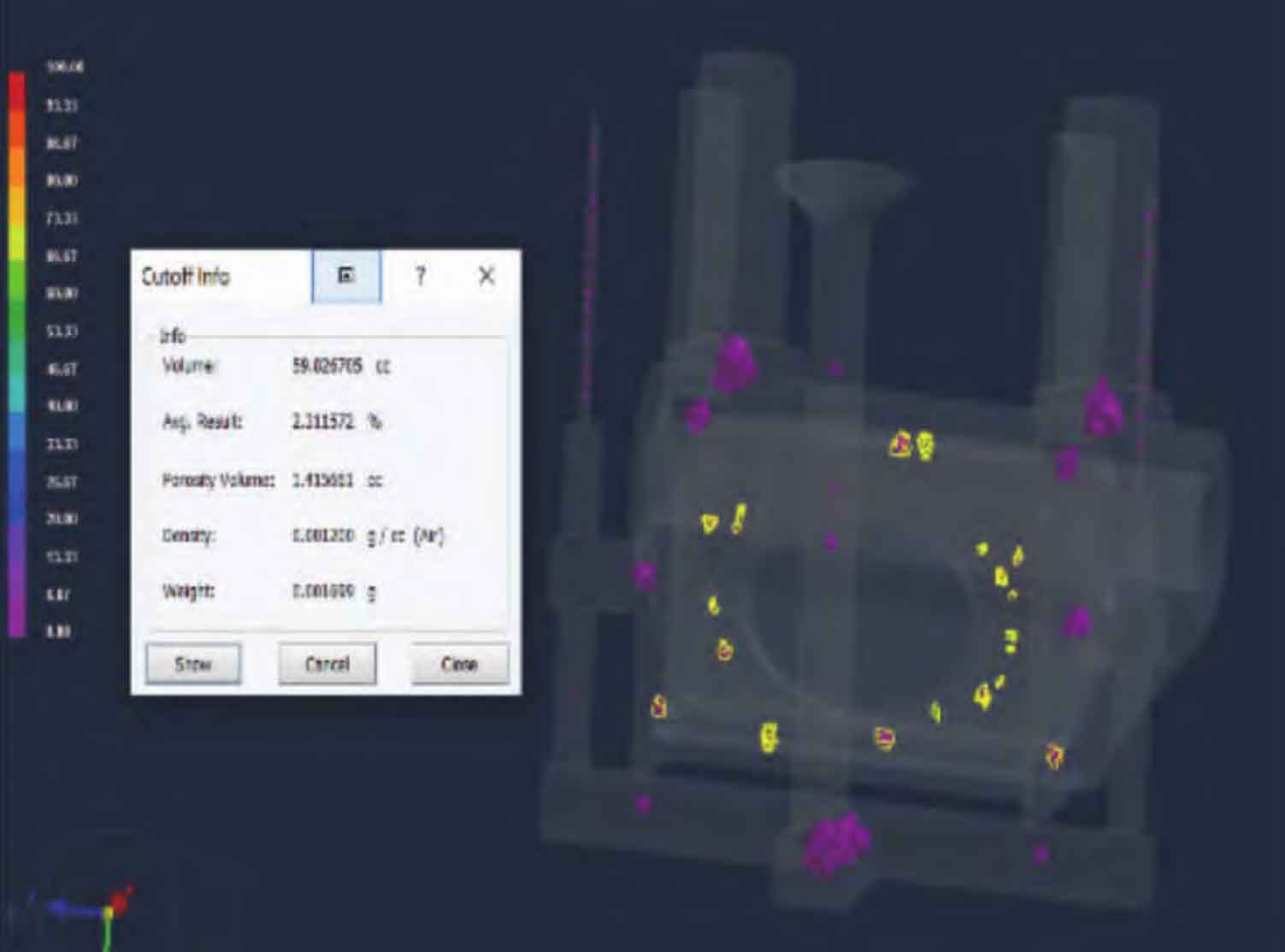

According to the range analysis, the order of influence of the two factors on the quality of shell steel castings is: pouring temperature>pouring speed. The optimal combination parameters are pouring temperature 1560 ℃ and pouring speed 1.6m/s. The pore distribution diagram is shown in the figure. It can be seen that the volume of pore defects in the shell steel casting is 1.416 cm3, which is smaller than the volume of pore defects in both the first and second schemes.

After process improvement, the qualification rate of steel castings has increased from 81% to 96%, and the process yield rate is 66%.