Ductile cast iron, renowned for its superior mechanical properties, is extensively used in various industrial applications. The performance of ductile cast iron can be significantly enhanced through optimized heat treatment processes. This article explores the various heat treatment methods and their effects on the microstructure and properties of ductile cast iron, aiming to provide insights into optimizing these processes for improved performance.

Introduction

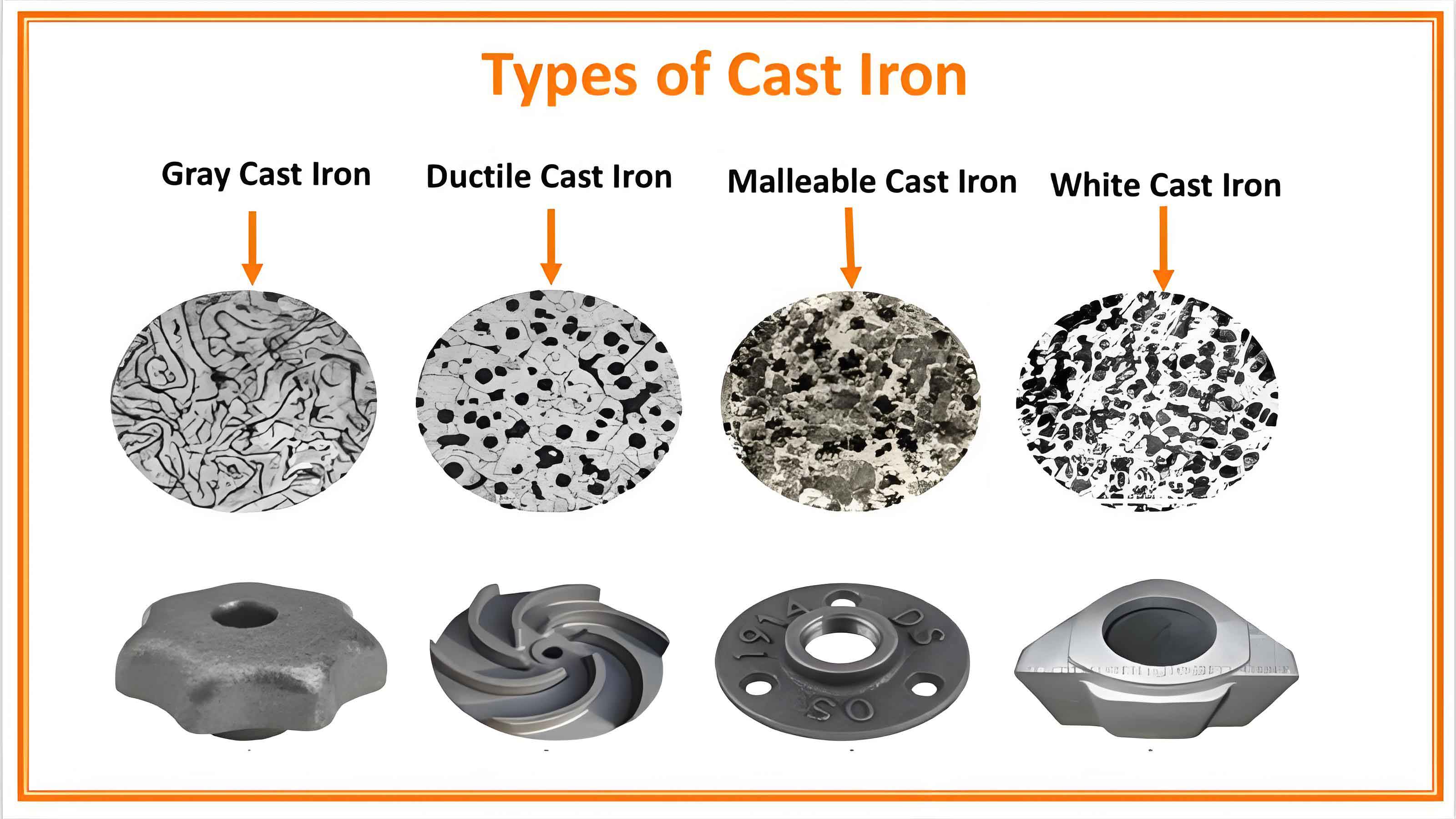

Ductile cast iron, also known as nodular cast iron, is characterized by its nodular graphite inclusions, which impart excellent mechanical properties such as high tensile strength, toughness, and wear resistance. The performance of ductile cast iron components can be further improved through appropriate heat treatment processes. This article discusses the impact of different heat treatment methods, including annealing, normalizing, quenching, and austempering, on the microstructure and properties of ductile cast iron.

Heat Treatment Processes

Annealing

Annealing involves heating the ductile cast iron to a temperature above its critical temperature, holding it at that temperature, and then slowly cooling it. This process aims to soften the material, improve its machinability, and relieve internal stresses.

Normalizing

Normalizing is a heat treatment process where the ductile cast iron is heated to a temperature above its critical range and then air-cooled. This process refines the grain structure, enhances the mechanical properties, and provides a uniform and fine microstructure.

Quenching

Quenching involves heating the ductile cast iron to a temperature above its critical range, followed by rapid cooling in a quenching medium such as water, oil, or air. This process increases the hardness and strength of the material but can also induce brittleness.

Austempering

Austempering is a specialized heat treatment process where the ductile cast iron is heated to a temperature above its critical range and then rapidly cooled to a temperature above the martensite start temperature, followed by holding at that temperature until transformation to bainite is complete. This process enhances the toughness and wear resistance of the material.

Experimental Methodology

The study involves subjecting ductile iron samples to various heat treatment processes. The microstructure is analyzed using optical microscopy and scanning electron microscopy (SEM), and the mechanical properties are evaluated through hardness, tensile, and impact tests.

Results and Discussion

Microstructural Analysis

The microstructure of ductile cast iron is significantly influenced by the heat treatment process.

Table 1: Microstructural Changes with Heat Treatment Processes

| Heat Treatment Process | Microstructural Changes |

|---|---|

| As-cast | Ferrite and pearlite matrix with nodular graphite |

| Annealing | Ferritic matrix, reduced internal stresses |

| Normalizing | Refined grain structure, pearlitic matrix |

| Quenching | Martensitic matrix, increased hardness |

| Austempering | Bainitic matrix, enhanced toughness |

Mechanical Properties

The mechanical properties of ductile cast iron are evaluated through hardness, tensile strength, and impact toughness tests.

Table 2: Mechanical Properties of Ductile Cast Iron Samples

| Heat Treatment Process | Hardness (HV) | Tensile Strength (MPa) | Impact Toughness (J) |

|---|---|---|---|

| As-cast | 200 | 500 | 15 |

| Annealing | 180 | 480 | 20 |

| Normalizing | 220 | 520 | 18 |

| Quenching | 300 | 600 | 12 |

| Austempering | 280 | 550 | 25 |

Wear Resistance

The wear resistance of ductile cast iron is evaluated using standardized wear tests.

Table 3: Wear Resistance of Ductile Cast Iron Samples

| Heat Treatment Process | Wear Rate (mg/Nm) | Durability Rating |

|---|---|---|

| As-cast | 0.75 | Moderate |

| Annealing | 0.70 | High |

| Normalizing | 0.65 | High |

| Quenching | 0.50 | Very High |

| Austempering | 0.45 | Very High |

Discussion

Annealing

Annealing ductile cast iron results in a predominantly ferritic matrix, which enhances the material’s machinability and reduces internal stresses. However, the reduction in hardness may limit its application in wear-intensive environments.

Normalizing

Normalizing refines the grain structure and produces a pearlitic matrix, resulting in improved strength and hardness. This process provides a balance between toughness and hardness, making it suitable for a wide range of applications.

Quenching

Quenching significantly increases the hardness and strength of ductile cast iron by forming a martensitic matrix. However, the increased brittleness may limit its use in applications requiring high toughness.

Austempering

Austempering produces a bainitic matrix, which enhances both toughness and wear resistance. This process offers an excellent combination of mechanical properties, making it ideal for applications in heavy machinery and other demanding environments.

Conclusion

Optimizing heat treatment processes is crucial for enhancing the performance of ductile cast iron. Annealing, normalizing, quenching, and austempering each offer unique advantages, and the choice of process depends on the specific requirements of the application. By carefully selecting and controlling the heat treatment process, the microstructure and properties of ductile cast iron can be tailored to meet the demands of various industrial applications.