1. Vibration consistency test

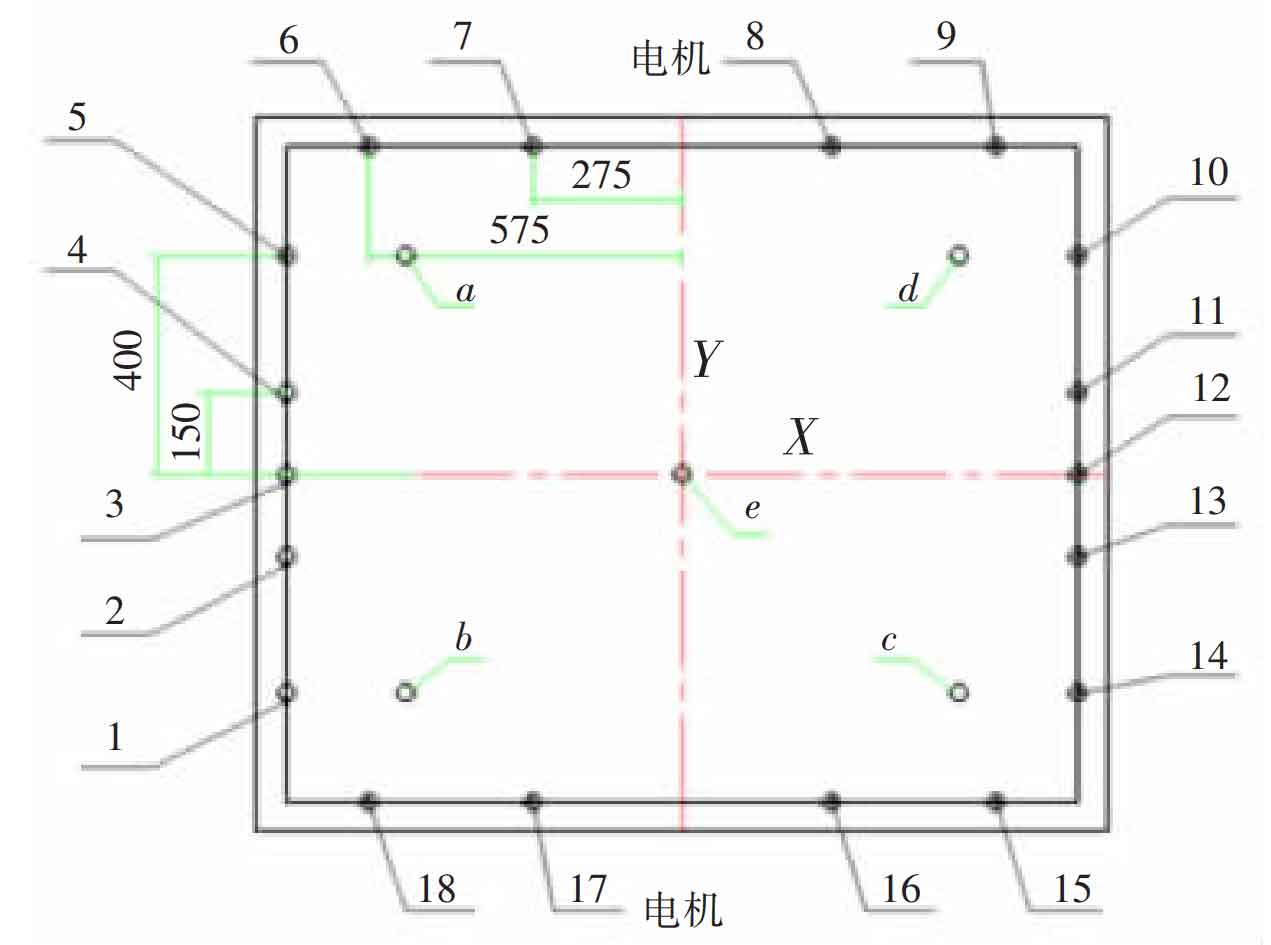

Take 18 positions on the sand box, and take 3 ~ 4 points at different heights at each position, as shown in Figure 1.

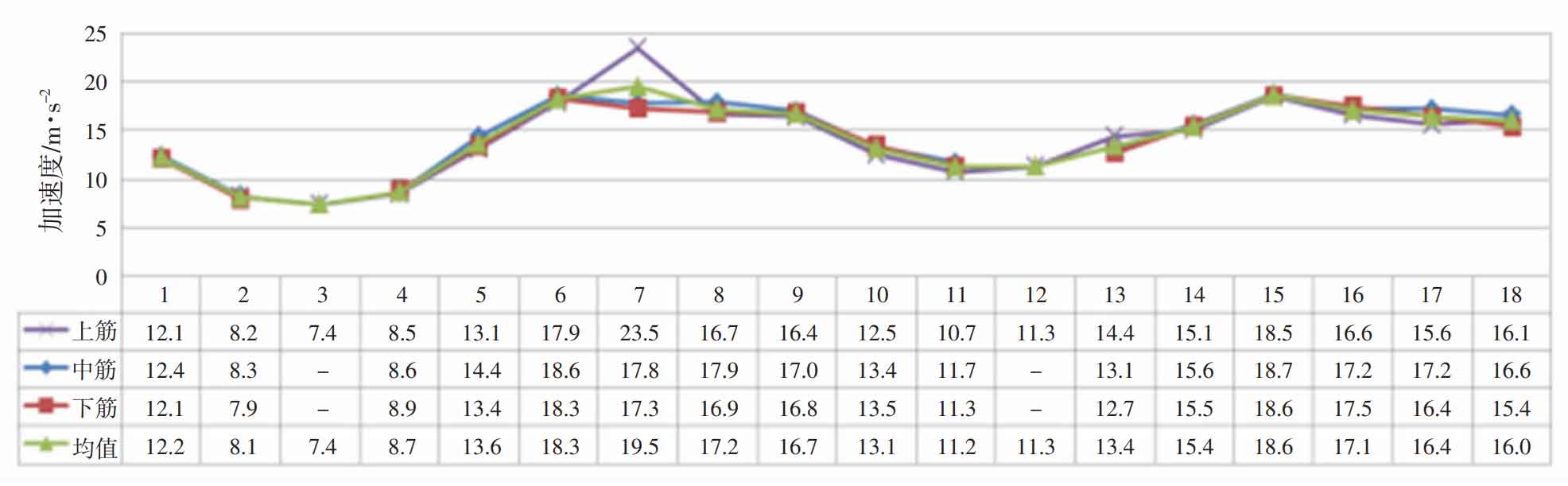

Acceleration in up and down direction (z direction), 90 ° unidirectional compaction is set on the compaction table, the compaction force is 85%, and the molding sand height is 300 mm. The accelerations of upper reinforcement, middle reinforcement and lower reinforcement are shown in Figure 2.

As can be seen from Fig. 2, the values of accelerations at different heights at the same location are basically close; Compared with the measured data of the original shaking table, the acceleration consistency at different positions is significantly improved; At positions 3 and 12, the acceleration is too small.

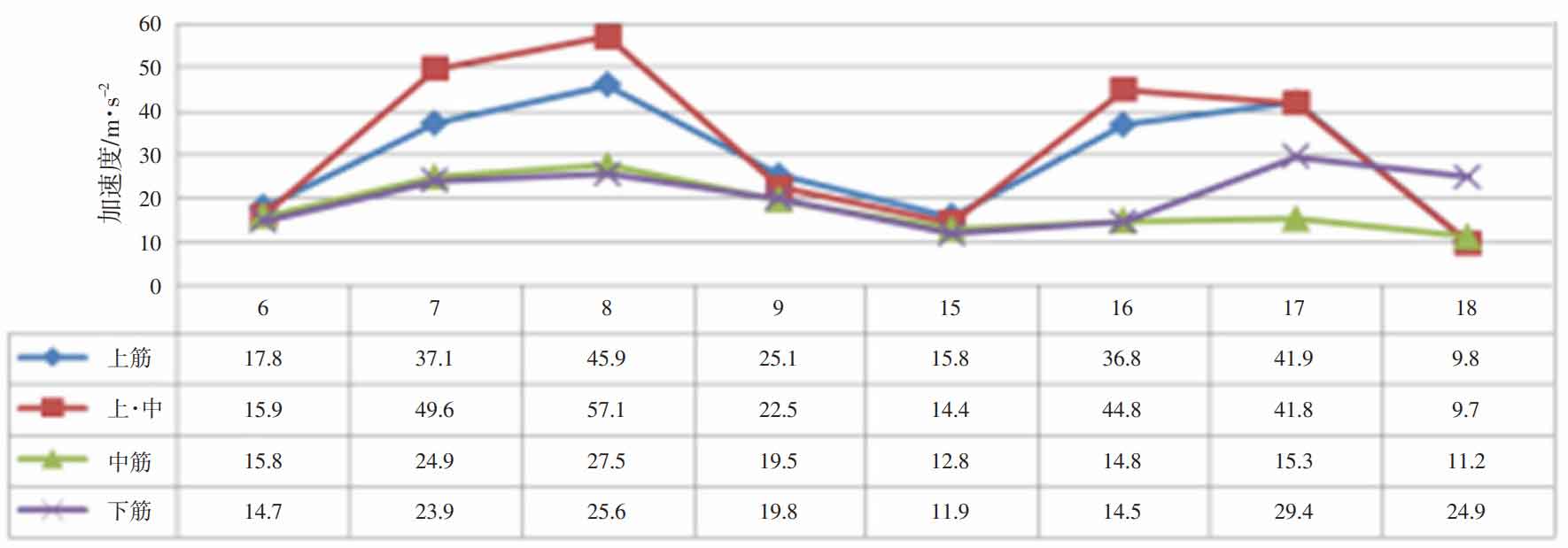

Acceleration in the fore-and-aft direction (Y direction), 0 degree one-way compaction is set on the compaction table, the compaction force is 85%, and the molding sand height is 300 mm. Select 8 points with high correlation with Y-direction acceleration, of which 6, 9, 15 and 18 correspond to the position of clamping point, and the accelerations at each point are shown in Figure 3.

As can be seen from Fig. 3, the acceleration at different positions at the same height shows the law of low clamping point and high middle; At the same position, the accelerations of the upper reinforcement and the middle reinforcement are close, and the accelerations of the middle reinforcement and the lower reinforcement are close, and the acceleration of the upper part is obviously greater than that of the middle and lower part.

2. Effect of fit clearance between vibrating table and sand box on acceleration

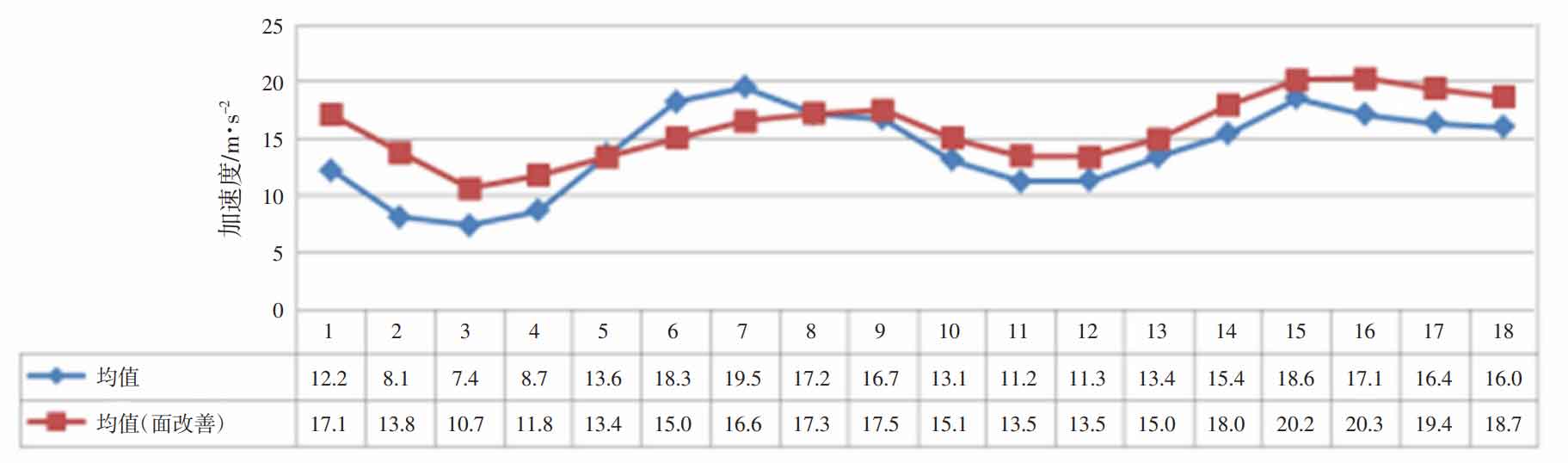

During the acceleration measurement, it is found that the sand box and the vibrating table adopt 45 ° surface matching. When the matching condition is poor (the matching is line contact or a small amount of surface contact), the acceleration near the matching surface is significantly lower than that at other positions. Therefore, grind the two matching surfaces. The final point surface contact conditions are as follows: 35% at position 6, 65% at position 9 and 70% at position 15, Location point 18 is 80%. Re measure the acceleration of 90 ° unidirectional vibration and 85% force, and the results are shown in Figure 4.

It can be seen from Figure 4 that the acceleration of other points except points 5 ~ 8 is significantly increased, indicating that the coordination between the sand box and the vibrating table has a great impact on the acceleration.

3. Mold filling effect test

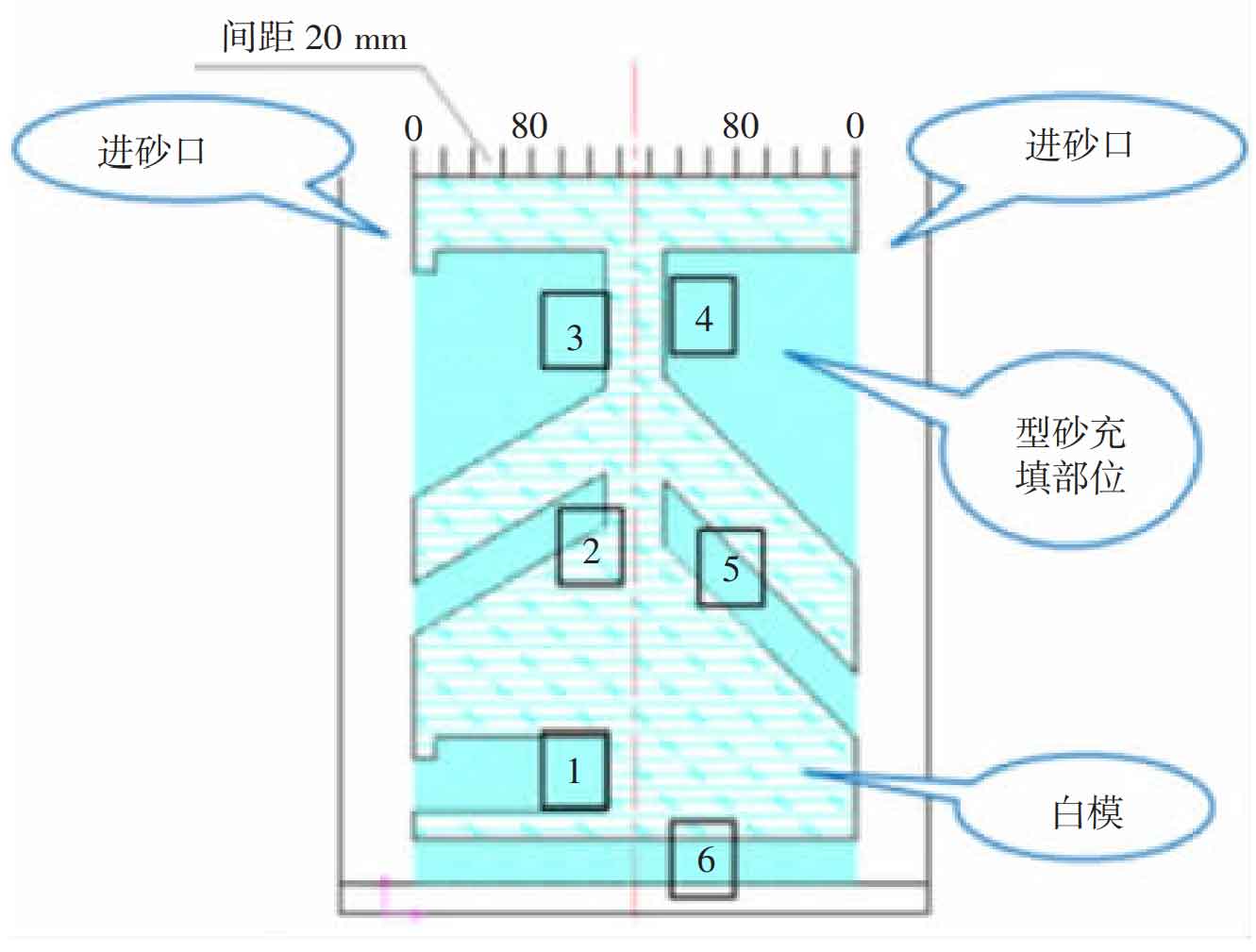

The filling test chamber shown in Figure 5 is used for testing, and the filling effect statistics can meet the requirements of transverse filling of 100mm.