Based on the existing working conditions of the factory (sand box size, sprue specification, ladle specification, automatic pouring line, etc.), the design of pouring system shall adopt the principle of rapid pouring, so as to maximize the rapid mold filling and shorten the pouring time as far as possible.

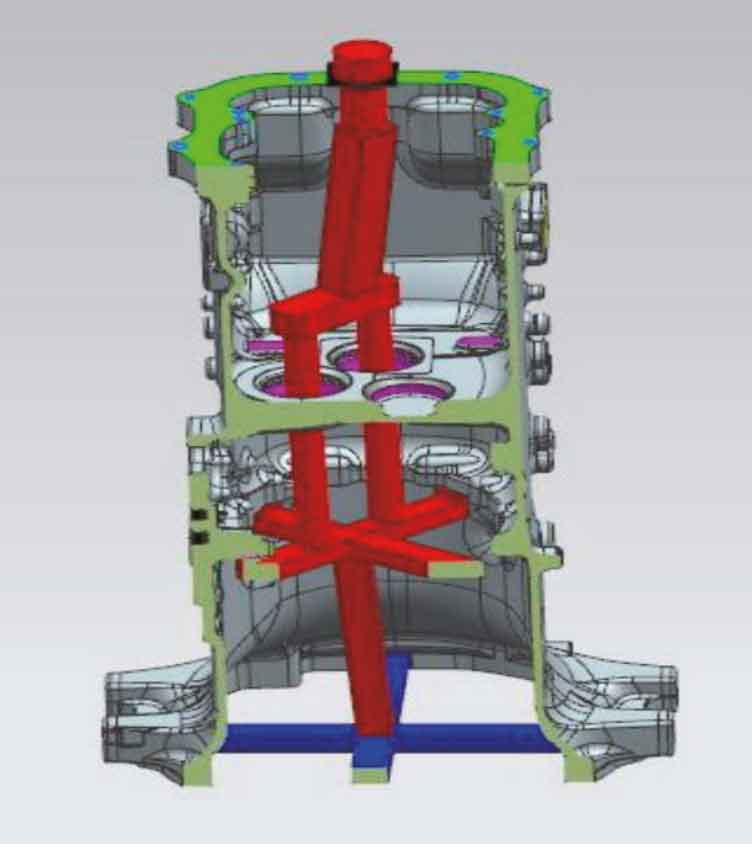

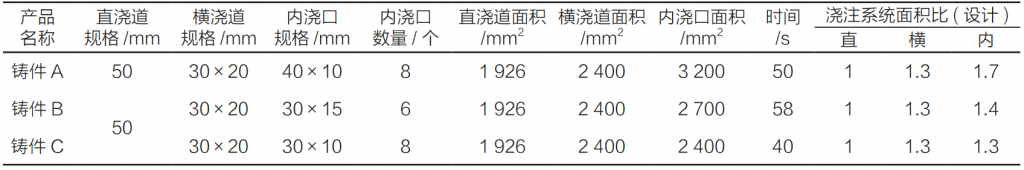

In the early stage of lost foam casting thin-wall gray cast iron gearbox shell casting a, the meter shaped stepped gating system with the combination of bottom injection and middle injection is adopted, and the diameter of the sprue is 50 mm and 30 mm × 4 Nos. of 20 mm runner, size 40 mm × There are 8 10 mm internal gates, and the ratio of the cross-sectional area of the sprue, transverse gate and internal gate is 1 ∶ 1.3 ∶ 1.7. The buried box method is lost foam casting. The non pressure bearing area of the thin-walled gray cast iron gearbox shell casting is downward (the large gate is downward), 6 pieces / box, and the pouring mass of a single box is 860kg.

In the early stage of lost foam casting thin-walled gray cast iron gearbox shell casting B, the single-sided stepped gating system with the combination of bottom injection and middle injection is adopted, and the sprue diameter is 50 mm and 30 mm × 4 20 mm transverse runners, size 30 mm × There are 6 15 mm internal gates, and the ratio of the cross-sectional area of the sprue, transverse gate and internal gate is 1 ∶ 1.3 ∶ 1.3. The buried box method is lost foam casting. The non pressure area of the thin-wall gray cast iron gearbox shell casting is downward (the large gate is upward), 6 pieces / box, and the pouring mass of a single box is 1000 kg.

The layout of the casting gating system of the thin-walled gray cast iron gearbox shell by lost foam casting is shown in Fig. 1 and Fig. 2. The relevant parameters of the casting gating system of the thin-walled gray cast iron gearbox shell by lost foam casting are shown in the table.