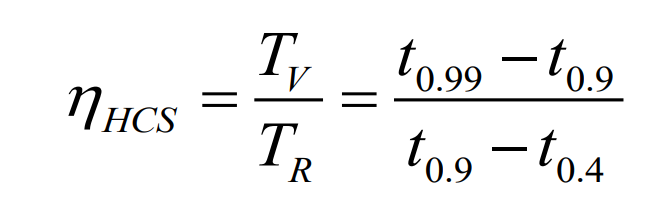

Hot crack defect refers to the casting defect when the solid rate of steel castings is close to 1.0 at the end of solidification, and the temperature is in the effective crystallization temperature range. According to the strength theory, the alloy itself within the effective crystallization temperature range is in the “brittle stage”, and the strength and plasticity of the alloy are low. At the end of solidification of steel castings, when the solid skeleton has formed and began linear shrinkage, due to the obstruction of shrinkage, the local shrinkage stress and plastic deformation of steel castings exceed the strength limit and elongation of the alloy at this temperature, and the steel castings will have hot crack defects. The greater the stress or plastic deformation during solidification, the greater the tendency of hot crack defects of steel castings. In ProCAST, the thermal crack index is used to qualitatively calculate the sensitivity of thermal crack defects, and the stress driven model is used for the calculation of thermal crack defects. The hot crack defect tendency coefficient is defined as:

Where: t0 99 represents the time corresponding to the solid fraction of 0.99. It can be seen that the longer the solid fraction is in the range of 0.9 ~ 0.99, the greater the tendency of hot cracking defects.