The sand casting surface obtained from the test is complete, but shrinkage cavities are found at the bearing holes of the box sand casting after machining, which are distributed circularly. The upper part of the pouring position is larger than the lower part. See Figure 1 for the specific location distribution.

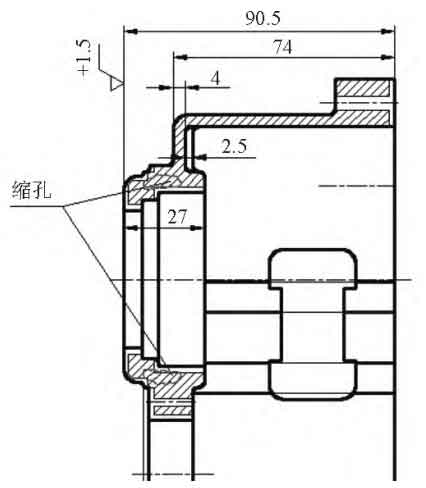

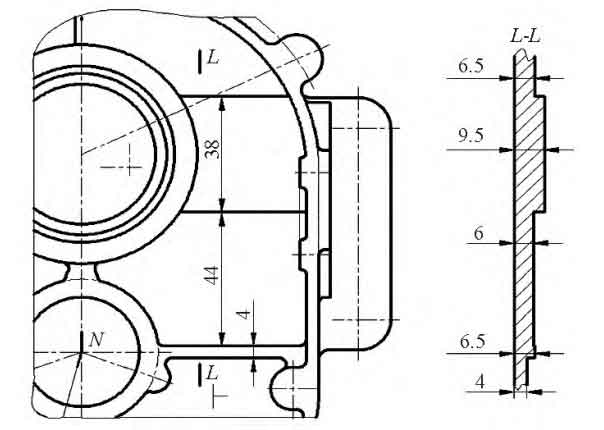

Through dissection, it was found that the surface of sand casting was normal, but shrinkage cavity was formed at the thick part at the junction of bearing hole and wall of sand casting. Even if cooling copper core rod was added at the boss, the defect could not be eliminated. Through analysis, due to the thin wall thickness of the sand casting, it is difficult for aluminum liquid to effectively feed the boss around the central circular hole of the sand casting through side bottom pouring, so the upper thin wall of the sand casting boss is required to form a thin and thick structure. Therefore, the following measures are taken: ① cooling air is introduced into the core of the mold, so that the main core can smoothly export the heat gathered here, and reduce the temperature of the middle boss; ② Make appropriate gradient changes to the wall thickness of sand casting, as shown in Figure 2. Increase the wall thickness of sand casting in the direction of riser shrinkage, so that the sand casting has a smooth feeding channel during solidification; ③ The upper part of the mold shall be preheated at the initial stage of pouring to maintain the appropriate mold temperature, ensure the uniform temperature requirements and realize the positive temperature gradient, so that the aluminum liquid has enough time to feed. The preheating temperature of the die shall be 300~350 ℃.

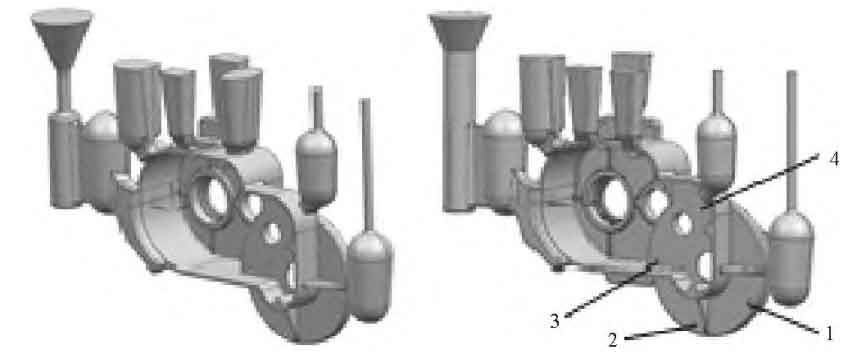

In addition, in order to reduce the chilling effect of the mold on the sand casting, and facilitate the demoulding and mold protection, the surface of the mold must be sprayed with paint to avoid cold shut, insufficient pouring or cold crack defects caused by local chilling of the sand casting. At the same time, along with the continuous production, the mold temperature will rise, and too high mold temperature will make the sand castings appear honeycomb pores and hot cracks, shortening the life of the mold. At this time, spraying paint is an effective means of mold cooling. After continuous mass production, the temperature of the metal mold designed according to the uniform temperature theory is relatively stable, and the heat absorption and release of the mold are balanced. For the box body, the mold temperature in summer shall be controlled within (350 ± 30) ℃, the pouring period shall be stabilized once every 3min, and the mold retention time shall be controlled within 70~90s; In winter, the mold temperature shall be controlled within the range of (350 ± 30) ℃, the pouring period shall be stable within 2.5 min, and the mold retention time shall be controlled within 60 s. The riser system of the die is reset, which makes the die opening mode simple and the riser easy to clean. See Figure 3 for the original scheme and the improved box gating and riser system.

It was found during the processing of the improved process sand casting box that the disc part of the box sand casting was seriously deformed. This was because the demoulding direction of the sand casting was inconsistent, which led to the main cavity of the sand casting pulling the casting belt to the moving mold, and it was difficult to demould the fixed mold, resulting in the disc deformation of the sand casting. Increase the demoulding force of the moving die edge to bring out the passive die of the sand casting disc, so the bottom hole of the disc is made, and two disc edges are set at the moving die side φ 8 mm pedestal (see 1 and 2 in Fig. 3b), adjust the mold lifting angle so that the sand casting remains on the movable mold when opening the mold, and then eject it with the ejector pin. Make small holes on the fixed mold side, and set two core ejector pins with a mold lifting angle greater than the other two. In addition to adjusting the demoulding force, it is also convenient for sand casting inspection and machining (see 3 and 4 in Fig. 3b).

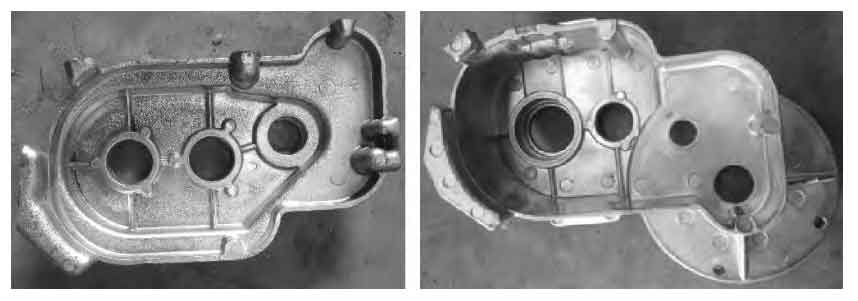

The process adaptability of the box cover is better than that of the box. The box cover can be formed under the mold temperature range of 300~350 ℃, and has good adaptability to the ambient temperature. The pouring cycle is about 130s, and the mold retention time is 40~80s. In addition, the middle production process of the main core of the mold does not require cooling air, which is simple to operate and successful in one-time development. The final gearbox assembly product is shown in Figure 4. Its surface quality is similar to that of the die casting, but its internal quality and mechanical properties are higher than that of the die casting.