1. Sand core design of sand mold casting

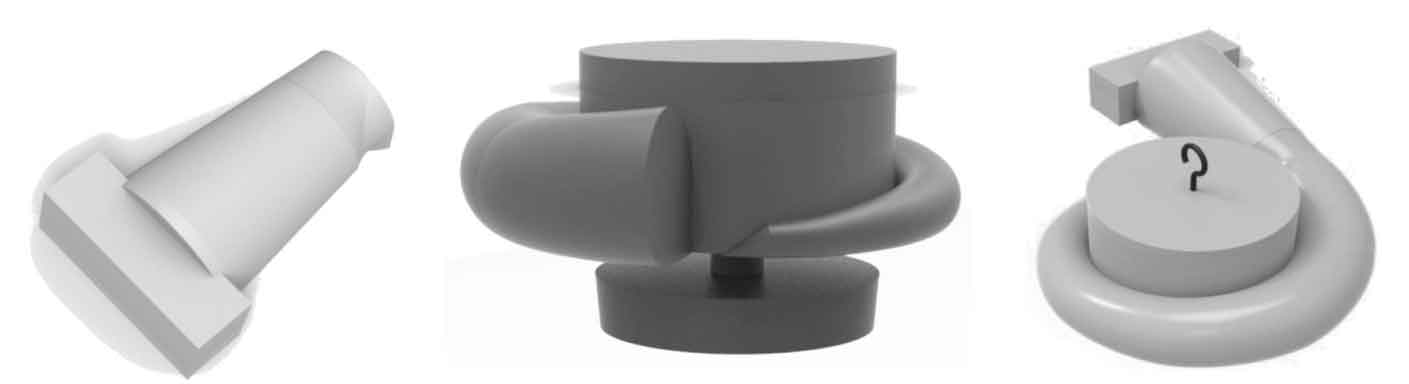

The core is made of furan resin self hardening sand. Because the inner wall of the spiral case is spiral as a whole, and the sand mold casting sand core is also spiral, in order to facilitate the core removal, the sand core is divided into 1# and 2# two parts. The removable sand core is adopted, and the core bone is added in the sand mold casting sand core to assemble the two parts of sand mold casting sand core into an integral sand core. As shown in Figure 1. The 1# sand core forms the flange pan head part, and the core head is designed as a rectangular horizontal core head; 2# sand core forming volute pipe and the middle cavity part, due to the small hole diameter at the bottom, in order to ensure the stability of support, the core head is designed to increase the vertical core head, with a height of 120 mm and a slope of 5 °. At the same time, the shaped wax line is embedded in the sand core, and the exhaust passage is pierced out of the central cylindrical core with a ventilation needle, which is helpful to the exhaust of sand mold casting sand core.

2. Design of sand mold casting core support

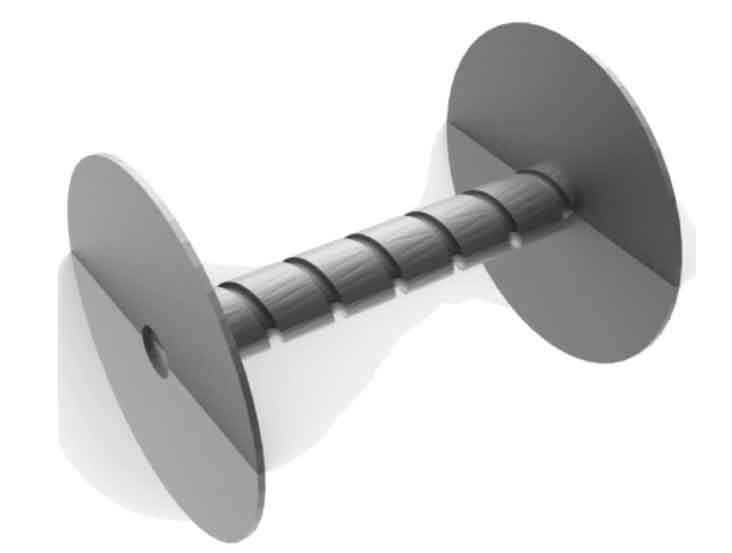

Because the sand core of sand mold casting is too high, it is difficult to be stable if it is fixed only by the core head. Therefore, it is considered to use core support to strengthen the sand core to play the role of auxiliary support. As the casting has high requirements for the quality of the bottom, the core support is designed with leak proof measures of threads and grooves. The core support material is low carbon steel, and the strength calculation method is adopted for the core support calculation. According to the data, the total cross-sectional area of the core support plate is calculated as a total = 165.6 mm2. Four single smooth column circular core supports dgy100 as shown in Figure 2 are selected to be evenly distributed on the large bottom surface to support the sand core of sand mold casting.