The production of large-scale machine components, such as bed frame castings, is a crucial aspect of the manufacturing industry. Box bed frames, specifically, serve as the backbone of heavy machinery, supporting various components and ensuring their precise operation. However, the production of these components often poses significant challenges, particularly in terms of quality control and defect prevention. This article delves into the process improvement of a specific box bed frame casting, highlighting the issues encountered, the strategies implemented for resolution, and the results achieved.

Introduction

Bed frame castings, particularly those of the box type, are intricate structures designed to withstand significant loads and maintain high levels of precision and durability. These castings are typically made from grey iron (e.g., HT300) due to its excellent castability, machinability, and wear resistance. Nevertheless, the production of box bed frame castings is fraught with complexities, primarily stemming from their large size, irregular shapes, and varying wall thicknesses.

In this study, we examine a box bed frame casting produced by a manufacturing company that encountered several quality issues during production. These issues included slag inclusion, choking bubbles, poor core brace fusion, and inadequate hardness, leading to a high defect rate and increased production costs. Through a comprehensive analysis of the existing process and the implementation of targeted improvements, we aimed to address these issues and enhance the overall quality of the casting.

1. Overview of the Bed Frame Casting

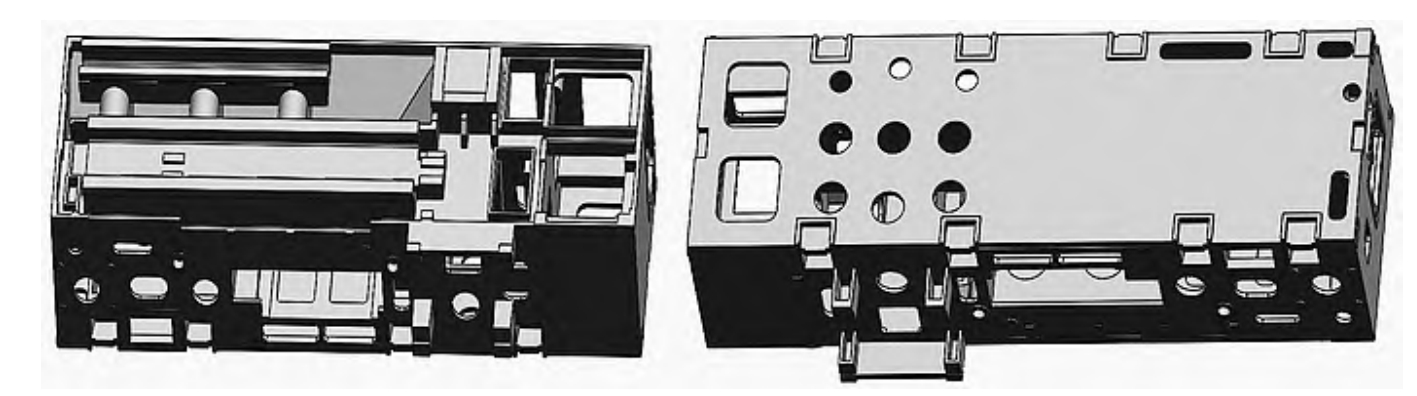

The box bed frame casting under study has a weight of 2989 kg and dimensions of 3100 mm × 1265 mm × 785 mm. It features a complex structure with a primary wall thickness of 15 mm, a maximum wall thickness of 90 mm, and varying geometries to accommodate various mechanical and functional requirements. The casting is made from HT300 grey iron, chosen for its suitability in withstanding high loads and maintaining dimensional stability.

The casting undergoes rigorous quality control to ensure that it meets the following criteria:

- No sand inclusion, porosity, slag inclusion, or cold shuts on machined surfaces.

- Defect-free oil chamber.

- Hardness of the guide rail exceeding 183 HBN.

- Freedom from structural porosity and inadequate hardness.

- Smooth exterior surfaces free from visible defects such as sand wash, sand adhesion, and bulges.

2. Original Process and Quality Issues

2.1 Original Casting Process

The initial casting process employed a specific orientation with the guide rail surface facing downwards and the bottom and oil tank surfaces facing upwards. The casting was positioned entirely on the upper box, with the gating system designed to minimize the influx of impurities into the mold cavity. The runner system was designed to ensure a smooth and even flow of molten iron, supporting the stability of the sand core and facilitating dimensional control.

Table 1: Raw Material Ratios for Melting

| Raw Material | Percentage |

|---|---|

| Pig Iron | 5% |

| Steel Scrap | 35% |

| Waste Steel | 60% |

| Ferro-Silicon | 2.0% |

| Ferro-Manganese | 0.7% |

Table 2: Chemical Composition Requirements for Molten Iron

| Element | Range (wt.%) |

|---|---|

| C | 3.12 ± 0.03 |

| Si | 1.40 ± 0.03 |

| Mn | 0.65 ± 0.03 |

| P | ≤ 0.04 |

| S | 0.08 – 0.12 |

| Ti | ≤ 0.030 |

| Pb | ≤ 0.0015 |

The melting process involved a controlled increase in temperature to 1490-1510°C for overheating, followed by a reduction to 1370-1390°C for pouring. Inoculation was performed using a two-stage nodularization process with silicon-iron additions.

2.2 Quality Issues

Despite the careful design of the casting process, several quality issues emerged:

- Inadequate Hardness: Four out of 13 castings produced had a hardness of 164-176 HBN, below the specified limit. Microstructural analysis revealed a pearlite content of only 80-90%, indicating insufficient hardenable elements.

- Sand Inclusion on the Upper Box Surface: Nearly every casting exhibited sand inclusion on the upper box surface, necessitating post-casting repairs and increasing production costs.

- Choking and Severe Blowholes: Seven castings were scrapped due to choking and severe blowholes, resulting in a defect rate of 53.8%. These defects were primarily concentrated around the core braces.

3. Root Cause Analysis

A thorough investigation was conducted to identify the root causes of the observed quality issues:

- Inadequate Hardness:

- The low pearlite content suggested insufficient elements promoting pearlite formation, such as manganese.

- A high carbon equivalent (CE) value may have promoted the formation of excessive ferrite, reducing overall hardness.

- Sand Inclusion:

- The planar upper box surface and narrow core gaps facilitated sand adhesion during core assembly.

- The limited number of risers on the upper box surface contributed to the entrapment of slag and impurities.

- Choking and Blowholes:

- The unstable fixation of specific cores (e.g., cores 10# and 11#) led to movement during pouring, causing choking and blowholes.

- Ineffective core brace fusion due to localized temperature fluctuations during pouring exacerbated the problem.

4. Process Improvement Strategies

To address the identified issues, a comprehensive set of process improvements were implemented, focusing on melting practices, casting design, and core assembly:

4.1 Melting Process Improvement

- Adjusted Chemical Composition: The manganese content was increased from 0.65% to 0.95% to promote pearlite formation.

- Optimized Carbon and Silicon Levels: The carbon content was reduced from 3.12% to 3.07%, and silicon from 1.75% to 1.71%, to balance hardenability and fluidity.

- Elevated Pouring Temperature: The pouring temperature was increased to 1380-1400°C to ensure better fluidity and reduce the risk of cold shuts.

Table 3: Revised Chemical Composition Requirements

| Element | Range (wt.%) |

|---|---|

| C | 3.07 ± 0.03 |

| Si | 1.71 ± 0.03 |

| Mn | 0.95 ± 0.03 |

| (Other elements remain unchanged) |

4.2 Casting Process Improvement

- 3D Printing of Cores: A shift to 3D-printed cores was implemented to improve dimensional accuracy and surface finish. Core braces were redesigned to minimize the need for external braces.

- Modified Core Assembly: The core assembly process was optimized to reduce sand adhesion and ensure stable core positioning. Core gaps were increased from 1 mm to 1.5 mm to facilitate easier assembly and reduce friction.

- Increased Risers: The number of risers on the upper box surface was increased from 10 to 16, enhancing the escape of impurities and gases during pouring.

4.3 Production and Quality Control

- Strict Process Control: Melting and pouring parameters were strictly monitored to ensure consistent quality.

- Post-Production Inspection: All castings underwent rigorous inspection for defects, with non-destructive testing (NDT) employed where necessary.

- Continuous Improvement: Regular reviews of the process and castings were conducted to identify areas for further optimization.

5. Results and Discussion

The implemented process improvements led to significant enhancements in casting quality:

- Improved Hardness: Continuous production of 40 castings yielded a consistent pearlite content of ≥95%, with hardness values ranging from 183 to 192 HBN, meeting customer specifications.

- Elimination of Defects: The incidence of sand inclusion, choking, and blowholes was drastically reduced. No choking or severe blowholes were observed in the subsequent castings, and the defect rate was reduced to below 1.5%.

- Cost Savings: The elimination of post-casting repairs and the reduction in scrap rates led to significant cost savings.

- Production Efficiency: The adoption of 3D-printed cores and optimized core assembly processes enhanced production efficiency and reduced cycle times.

Table 4: Comparison of Pre- and Post-Improvement Results

| Quality Metric | Pre-Improvement | Post-Improvement |

|---|---|---|

| Defect Rate | 53.8% | <1.5% |

| Average Hardness (HBN) | 164-176 | 183-192 |

| Pearlite Content (%) | 80-90 | ≥95 |

| Scrap Rate | High | Low |

| Production Efficiency | Moderate | High |

6. Conclusion

The process improvement of the box bed frame casting addressed several critical quality issues, resulting in significant enhancements in casting performance and production efficiency. By optimizing the chemical composition of the melt, adopting advanced core manufacturing techniques, and implementing rigorous quality control measures, we were able to consistently produce castings that met or exceeded customer specifications.

The success of this project underscores the importance of continuous process improvement in the casting industry. Regular reviews of production processes, coupled with the adoption of innovative technologies, can lead to substantial gains in quality, efficiency, and cost-effectiveness. Future work could explore further optimizations in material selection, melting practices, and casting design to push the boundaries of casting performance even further.