From the simulation results, it can be seen that the heat loss at the thin wall of the casting is fast, and the feeding channel is blocked after solidification. As the thin wall is not processed and has grid rib structure, it is impossible to set subsidies to realize the sequential solidification between the central hot spot and the top riser, and only the side riser feeding can be set at the central hot spot.

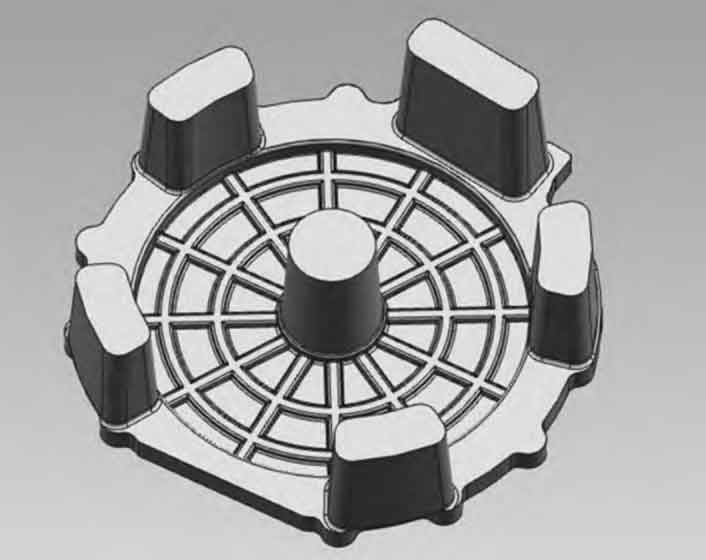

During mold filling, the mold cavity is inclined from horizontal to vertical, the riser is on the horizontal side of the casting, and there is no gravity to provide feeding pressure. The aluminum liquid will not flow smoothly to the fed part, and it is not easy to achieve good feeding effect. In order to solve the problem of feeding pressure, the filling process was adjusted from vertical tilt to horizontal, so that gravity feeding could be used after casting tilt. In the original scheme, the top and side risers are adjusted to five waist shaped risers, which reduce the total volume of risers and greatly improve the process yield while feeding the thick wall area of castings. See Figure 1 for the optimization scheme.

1. Optimization scheme simulation

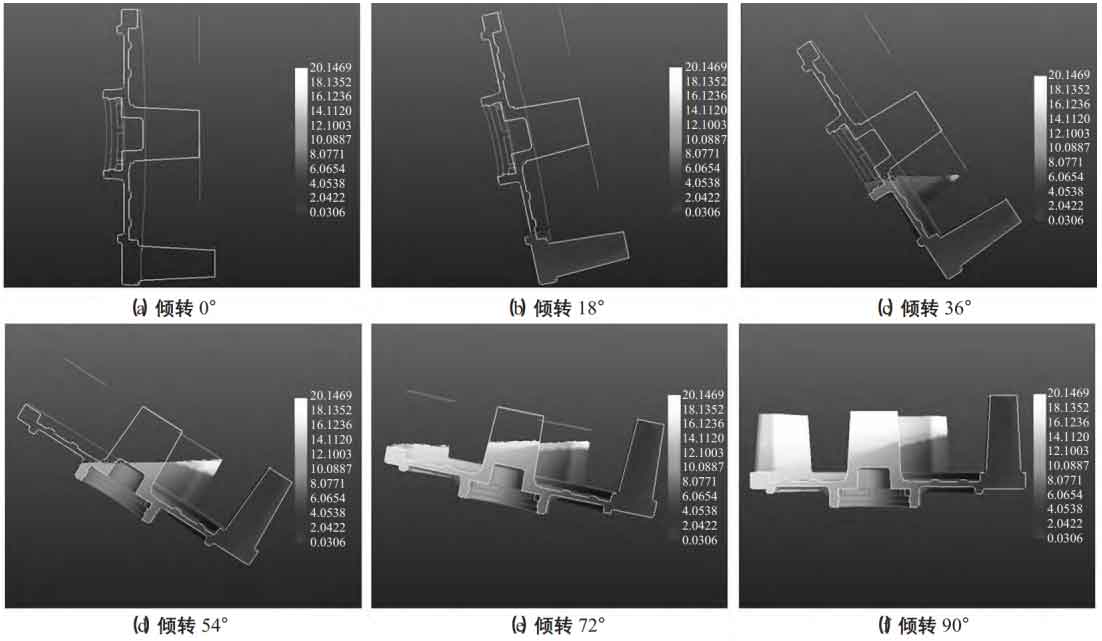

The optimized scheme is simulated, and the filling process is shown in Figure 2. The mold cavity is tilted from vertical to horizontal. With the increase of the tilt angle, the aluminum liquid enters the mold cavity smoothly from the bottom side, and the front end of the liquid level finally enters the riser. Gas and oxide slag can be discharged through the riser. It can be seen from the tilting process that the boundary between the filled area and the unfilled area is obvious, and there is no intersection, which reduces the turbulence.

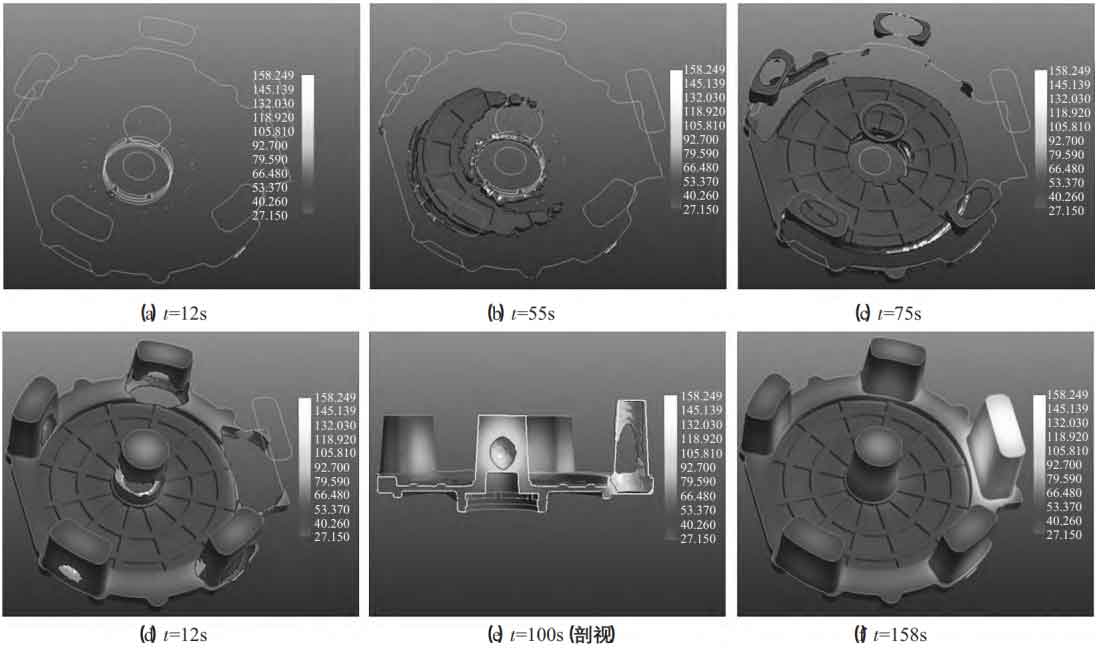

The solidification process is shown in Figure 3. During solidification, there is always a feeding channel between the riser and the fed part, and the expansion angle is toward the riser. After tilting, the aluminum liquid in the riser can be fed under gravity, and the shrinkage defects in the original scheme are solved.

2. Production verification

The production verification shows that the casting surface quality is good, and there are no casting defects after X-ray flaw detection and processing. In the original plan, the casting with gating system is 20.5kg, and the process yield is 22%. In the optimized plan, the casting with gating system is 9kg, and the process yield is 50%, which greatly improves the process yield. See Fig. 4 for the castings produced by the optimized scheme and Fig. 5 for the finished products after processing.

The process plan was optimized. A side riser was set in the center of the new energy front end cover, and the tilting mode was changed from vertical to horizontal and from horizontal to vertical, so that the gravity feed of the riser could be used after the casting tilting was completed, which solved the shrinkage problem at the center of the casting, reduced the porosity and slag inclusion defects, and improved the casting quality and process yield.