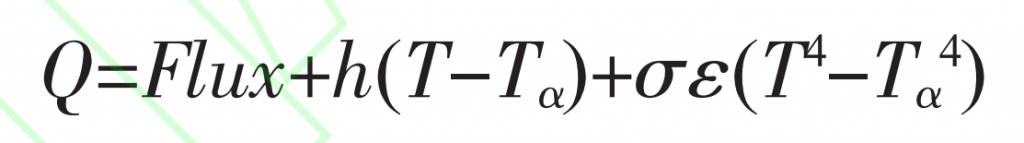

Switch to the cast module, set simulation parameters, edit materials on the user defined page, edit the composition of 304 stainless steel in the table, and select zircon sand as the shell material. The traditional process parameters set the pouring temperature to 1550 ℃ and the preheating temperature of the mold shell to 1150 ℃. Gravity filling is used, and the pouring speed is 1.5 kg/s. The interface heat transfer coefficient is selected as COINC (a heat transfer method where different materials on both sides of the interface have a temperature difference between the investment casting and the mold). The interface heat transfer coefficient is selected as COINC type, and the interface heat transfer coefficient Q of 304 stainless steel and zircon sand is calculated based on the following model.

In the formula, Q is the interfacial heat transfer coefficient; Flux is the heat flux rate; T is the surface temperature of the investment casting; T α Is the ambient temperature; ε Is the reflectivity of the material; H is the convective heat transfer coefficient; σ Is the StefanBolzman constant.

| C | Cr | Mn | Mo | Ni | S | Si |

| 0.08 | 18 | 1.5 | 0.5 | 8 | 0.03 | 1 |

Combining the calculation results and selecting the interface heat transfer coefficient Q=500W/(m2 · K) between 304 stainless steel and zircon sand.