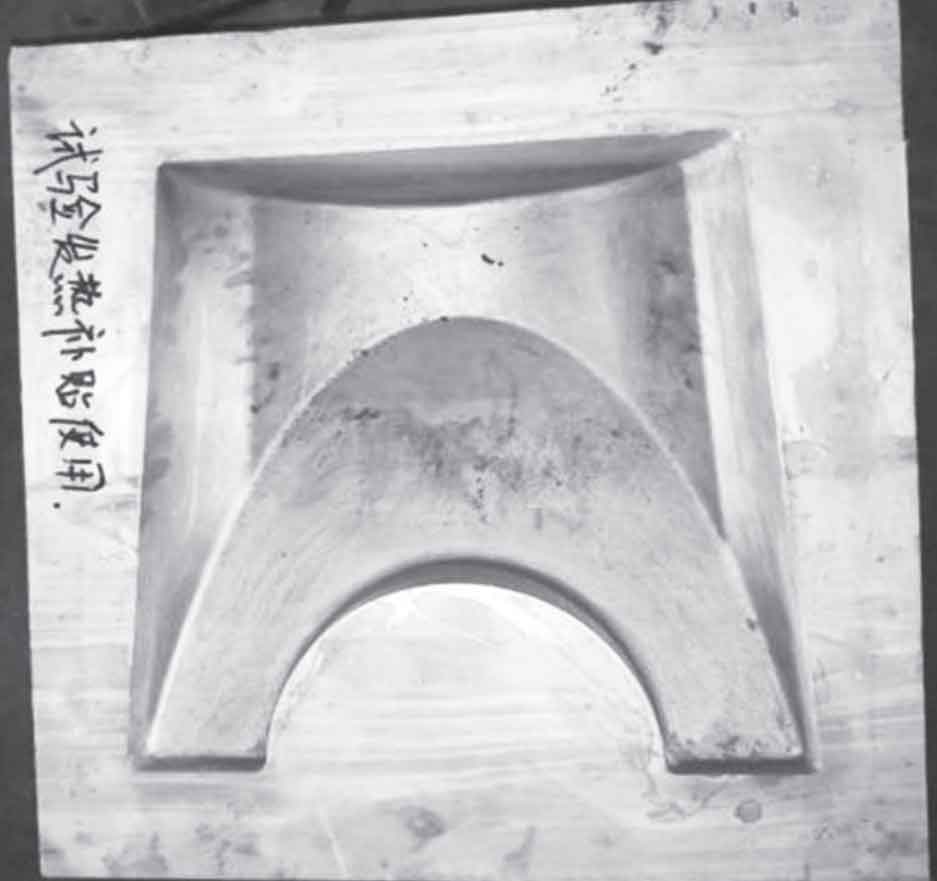

1. Production of heat subsidy for sand casting

Mix the powdered heating material and binder evenly according to the required proportion, and prefabricate the heating subsidy with sand casting subsidy core box (Fig. 1).

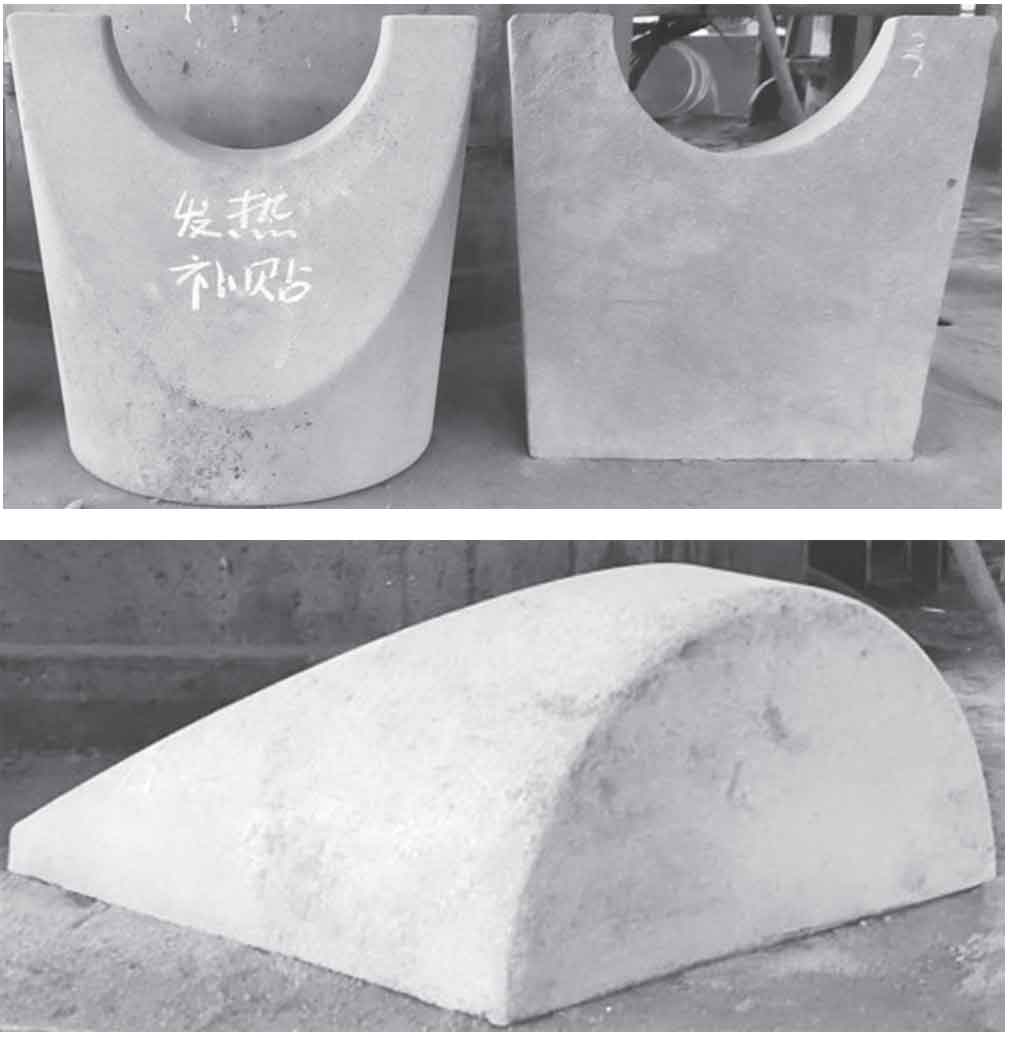

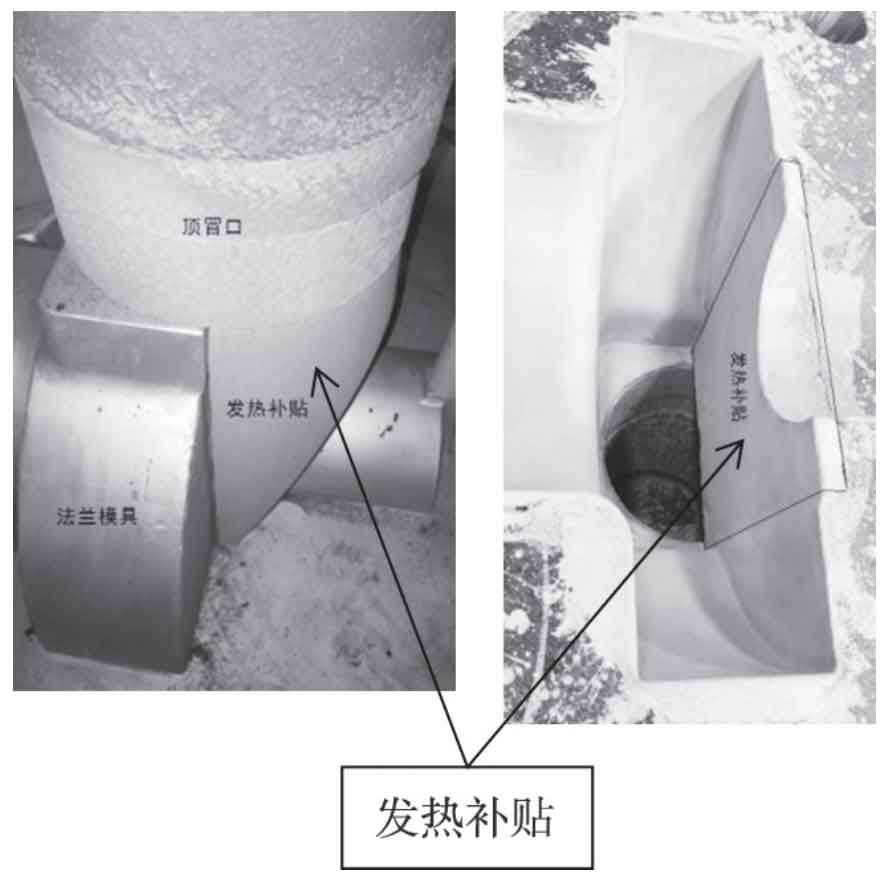

2. Sand casting molding, box closing and pouring

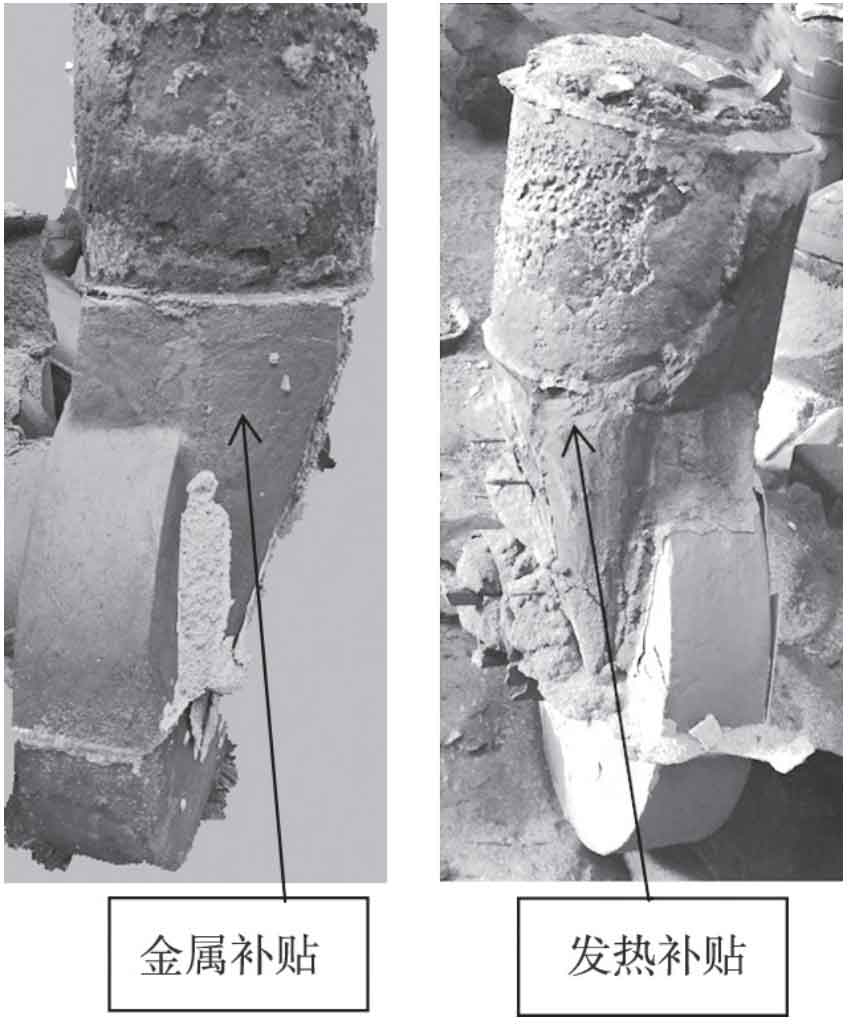

Before sand casting molding, place the heating subsidy at the design position, and then shape. Pay attention to placing the exhaust pipe at the heating subsidy position to ensure smooth exhaust during heating agent reaction. The heating subsidy is painted with the same paint as the sand mold, and the box can be poured after drying. Figure 2 shows the heat allowance and metal allowance of sand casting, and their positions are shown in Figure 3.

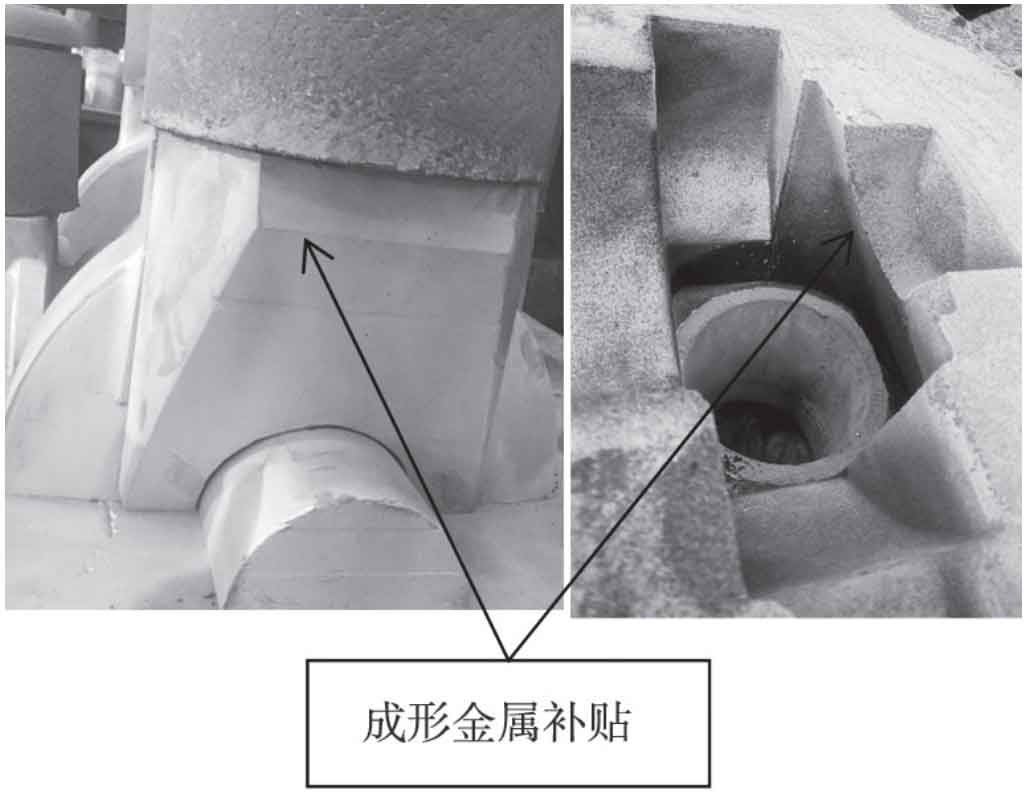

3. Surface inspection of sand castings

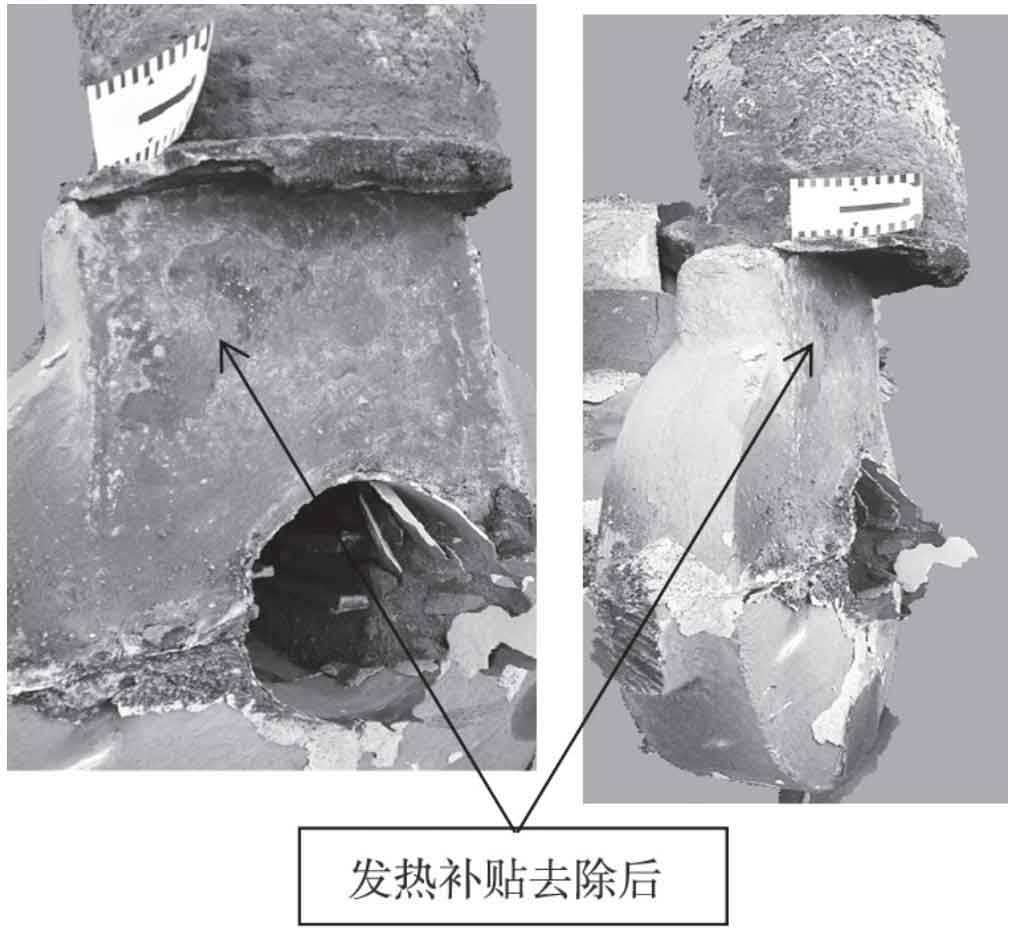

See Fig. 4 for the metal allowance and heat insulation allowance at the flange riser after sand casting and sand cleaning. See Fig. 5 for the state of the flange riser after the heat subsidy is removed. It can be seen from the figure that the heating and thermal insulation subsidy material after reaction can be easily removed with vibration sand falling. Through visual inspection, the surface of sand casting is free of pores and sand sticking defects, and the surface is smooth and close to the surface of sand casting. The removal of metal subsidies is very troublesome. It needs to be removed by sawing machine or plasma gun cutting, which will increase the production cost of sand castings.

4. Internal quality inspection of sand castings

Radiographic inspection was conducted on the flange positions of two sand castings cast with metal subsidy and heat preservation and heating subsidy process scheme. It was found that there were no casting defects inside, which met the quality inspection requirements of customers.