In my extensive experience within the foundry industry, the manufacture of特大heavy-section ductile iron castings presents a unique set of challenges and opportunities. The successful production of a critical component like a butterfly valve plate, weighing 24 tonnes with wall thicknesses exceeding 100 mm, is a testament to meticulous engineering and process control. This account details our first-hand production practice for such an oversize ductile iron casting, emphasizing the integration of simulation, metallurgical design, and rigorous quality assurance. The ductile iron casting process for these massive parts demands attention to every detail to prevent defects like graphite degeneration, shrinkage, and segregation that are common in thick sections.

The application of ductile iron in large valves has grown significantly due to its favorable combination of mechanical properties, castability, and cost-effectiveness. Compared to steel, ductile iron offers excellent damping capacity and good machinability, making it ideal for components like butterfly plates in hydroelectric power stations. However, the slow cooling inherent in heavy-section ductile iron castings can lead to microstructural anomalies. Our objective was to produce a QT450-10 grade ductile iron casting meeting stringent nondestructive testing standards, which required a holistic approach from design to finishing.

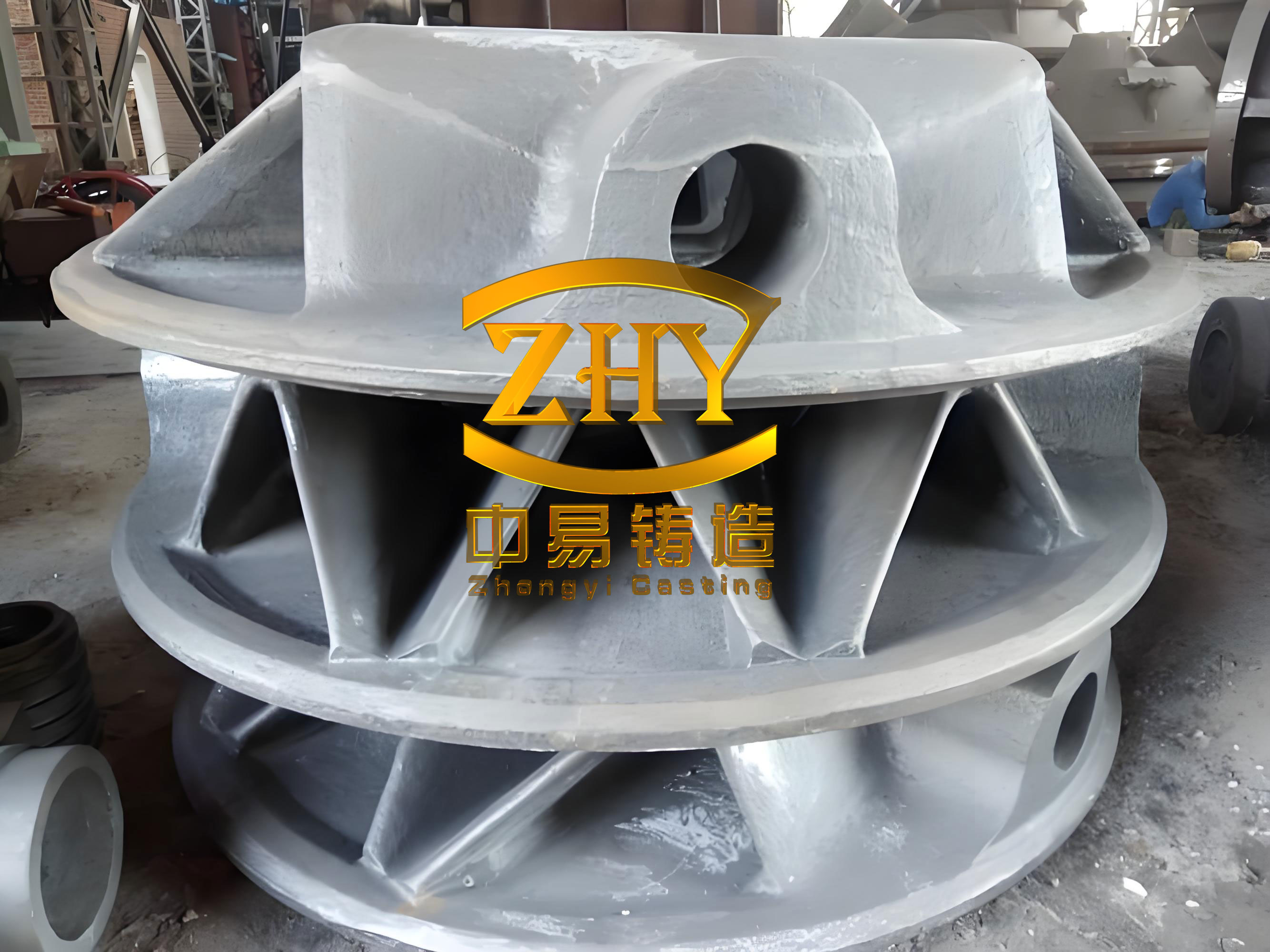

The foundation of a sound ductile iron casting lies in its工艺design. For this eccentric butterfly plate, we oriented the large flat surface downward to facilitate molding and feeding. A two-part flask was used, with molds made from phenolic-modified furan resin self-hardening sand. The gating system was designed as a bottom-pouring, open type to ensure smooth filling and minimize turbulence. The principle governing the cross-sectional areas was strictly adhered to: $$ \Sigma A_{\text{runner}} : \Sigma A_{\text{横}} : \Sigma A_{\text{直}} = 1.8 : 1.23 : 1 $$. This ratio helps control metal velocity and reduces slag entrainment. A slag trap was incorporated to filter oxides and inclusions during pouring.

To address the prolonged solidification of this thick ductile iron casting, we employed a combination of chills and insulated risers. Chills, strategically placed, accelerate cooling at thermal centers, minimize temperature gradients, and shorten the total solidification time. We aimed to keep this time under 2 hours to avoid adverse metallurgical changes. Insulated risers were selected to enhance feeding efficiency and concentrate floating slag and oxides away from the casting body. The placement and sizing of these elements were optimized using numerical simulation.

Computer simulation has become an indispensable tool in modern foundry practice, especially for complex ductile iron castings. We utilized ProCAST software to iteratively refine our工艺. By modeling the solidification process with chills and risers in place, we could predict shrinkage porosity locations accurately. The simulation output showed that major shrinkage was concentrated within the insulated risers, with only minor, dispersed porosity predicted in isolated areas between chills, primarily on the upper surfaces. This confirmed the overall viability of our design, as the combined effects of feeding from the gates and the graphite expansion inherent to ductile iron would compensate for these minor issues. The simulation allowed us to proceed with confidence, significantly reducing the trial-and-error周期.

The metallurgical preparation for this heavy ductile iron casting is arguably the most critical phase. We began with化学composition design, targeting the properties of QT450-10. Carbon equivalent (CE) is a crucial parameter for castability and soundness. We controlled it near the eutectic point using the formula: $$ CE = C + \frac{1}{3}(Si + P) $$. A typical target range for our ductile iron casting was 4.3–4.5%. Table 1 summarizes the designed composition ranges.

| Element | Target Range | Role & Rationale |

|---|---|---|

| C | 3.4 – 3.6 | Promotes fluidity and graphite expansion for self-feeding. |

| Si | 2.3 – 2.5 | Strong graphitiser; stabilizes ferrite but excessive amounts promote chunk graphite in heavy sections. |

| Mn | ≤ 0.3 | Kept low to minimize segregation and carbide formation at grain boundaries. |

| P | ≤ 0.04 | Minimized to avoid phosphide eutectics that embrittle the matrix. |

| S | ≤ 0.02 | Low levels reduce球化agent consumption and improve nodule count. |

| Mgres | 0.04 – 0.06 | Residual magnesium ensures球化; excess causes dross and shrinkage. |

| REres | 0.01 – 0.02 | Residual rare earths counteract trace impurities and aid nodulizing. |

The selection of raw materials is paramount. We used high-purity pig iron specifically for ductile iron production, constituting 80% of the metallic charge, with strict control over trace elements (sum < 0.1%). The remaining 20% was low-manganese carbon steel scrap to provide a clean iron base. Melting was conducted in a medium-frequency coreless induction furnace. After melting and skimming, the iron was superheated to 1500°C and held for 5-10 minutes to homogenize and reduce gas content before being allowed to cool to the treatment temperature.

球化and inoculation are the heart of producing a high-quality ductile iron casting. For this massive section, we employed the wire-feeding method due to its precise control and reduced fade. Treatment was performed at 1360–1380°C. A high-magnesium cored wire (9–13 mm diameter) was fed for球化, followed by a ferro-silicon based inoculant cored wire. The reaction can be conceptually described by the following relationship for magnesium yield: $$ \eta_{Mg} = \frac{Mg_{res}}{Mg_{added}} \times 100\% $$ where we aimed for a high efficiency to maintain the target residual levels. Immediately after treatment, the ladle was covered with charcoal powder to insulate and collect slag. During pouring at 1320–1360°C, we performed stream inoculation by adding 0.1% barium-silicon inoculant. The pouring sequence followed a “slow-fast-slow” pattern to minimize oxidation.

The success of our ductile iron casting process was validated through rigorous testing of attached test blocks, which simulate the casting’s cooling conditions. The test block design, as shown in our documentation, ensured representative sampling. Metallographic examination revealed a microstructure with over 90% nodularity, graphite size grade 6, and a fully ferritic matrix, which is essential for the required ductility. The mechanical properties extracted from these test blocks are presented in Table 2, demonstrating full compliance with QT450-10 specifications.

| Property | Standard Requirement (QT450-10) | Measured Value |

|---|---|---|

| Tensile Strength (MPa) | ≥ 390 | 430 |

| Yield Strength (MPa) | ≥ 260 | 285 |

| Elongation (%) | > 8 | 15.5 |

The integrity of the final ductile iron casting was subjected to comprehensive nondestructive evaluation. 100% ultrasonic testing according to EN 12680-3 and magnetic particle inspection of all machined surfaces per EN 1369 were conducted, with all results meeting the stringent Level 2 acceptance criteria. Furthermore,本体ball化rate assessment confirmed consistency, and surface roughness met the specified grades. It is noteworthy that the entire process was designed to eliminate the need for任何weld repair, a critical requirement for this application.

From a quality control perspective, monitoring key thermal parameters is vital. The solidification time (tsolid) for a thick ductile iron casting can be estimated using Chvorinov’s rule, though with modifications for graphite expansion: $$ t_{\text{solid}} = B \left( \frac{V}{A} \right)^n $$ where V is volume, A is cooling surface area, and B & n are constants dependent on mold material and alloy. Our use of chills effectively reduced the effective modulus (V/A) at critical locations, keeping tsolid within the desired window to prevent石墨degeneration.

Inoculation effectiveness, crucial for achieving a high nodule count in this heavy ductile iron casting, can be influenced by several factors. The fading of inoculation effect over time or temperature can be modeled approximately. The nodule count (N) is a function of inoculation potency and cooling rate. While a precise universal formula is complex, we empirically controlled it through multiple inoculation stages (wire feeding + stream inoculation) to ensure a fine, uniform graphite distribution throughout the massive section.

Furthermore, the management of element segregation, particularly锰and硅, in thick-section ductile iron castings is a constant concern. The degree of microsegregation can be described by the Scheil-Gulliver equation for a non-equilibrium solidification: $$ C_s = k C_0 (1 – f_s)^{k-1} $$ where Cs is the composition in the solid, C0 is the initial liquid composition, k is the partition coefficient, and fs is the solid fraction. For锰(k < 1), it enriches in the last-to-freeze regions, potentially forming carbides. Our low锰content and accelerated cooling via chills mitigated this risk significantly.

The entire production campaign for this oversize ductile iron casting was a systematic工程. Each step, from the initial simulation to the final inspection, was interlinked. The use of advanced simulation software like ProCAST provided a predictive window that allowed for工艺optimization before任何metal was poured, saving time and resources. The choice of high-purity charge materials formed the foundation for clean iron with minimal干扰elements. The wire-feeding球化process offered superior reproducibility and control over residual levels compared to traditional sandwich methods, which is especially important for consistent quality in large ductile iron castings. Multiple inoculation steps countered the inevitable fading effects during the long pouring and solidification sequence inherent to a 24-tonne casting.

In conclusion, the production of特大, thick-section ductile iron castings for critical applications like butterfly valves demands an integrated, science-based approach. Our实践demonstrates that success hinges on several pillars: (1) Thorough工艺design and validation through numerical simulation to predict and eliminate defects. (2) Stringent control over raw material quality and chemical composition, particularly for elements that segregate or interfere with球化. (3) Employing modern, controlled treatment methods like wire feeding for reliable and reproducible球化and inoculation. (4) Implementing accelerated cooling techniques such as chills to refine microstructure and shorten solidification time. (5) Enforcing rigorous process discipline and multi-stage quality verification throughout the entire manufacturing chain of the ductile iron casting. This holistic methodology ensures that the final ductile iron casting not only meets but exceeds the mechanical and integrity specifications, providing a reliable and cost-effective solution for demanding industrial valve applications. The knowledge gained from producing such a massive ductile iron casting contributes significantly to the advancement of heavy-section foundry technology.