From April to December 2020, ZHY casting fully applied the optimized new sand mold casting process to production, and produced a total of 2800 shell steel castings. The overall product quality has reached a new level, especially the improvement effect of sand inclusion and crack defects.

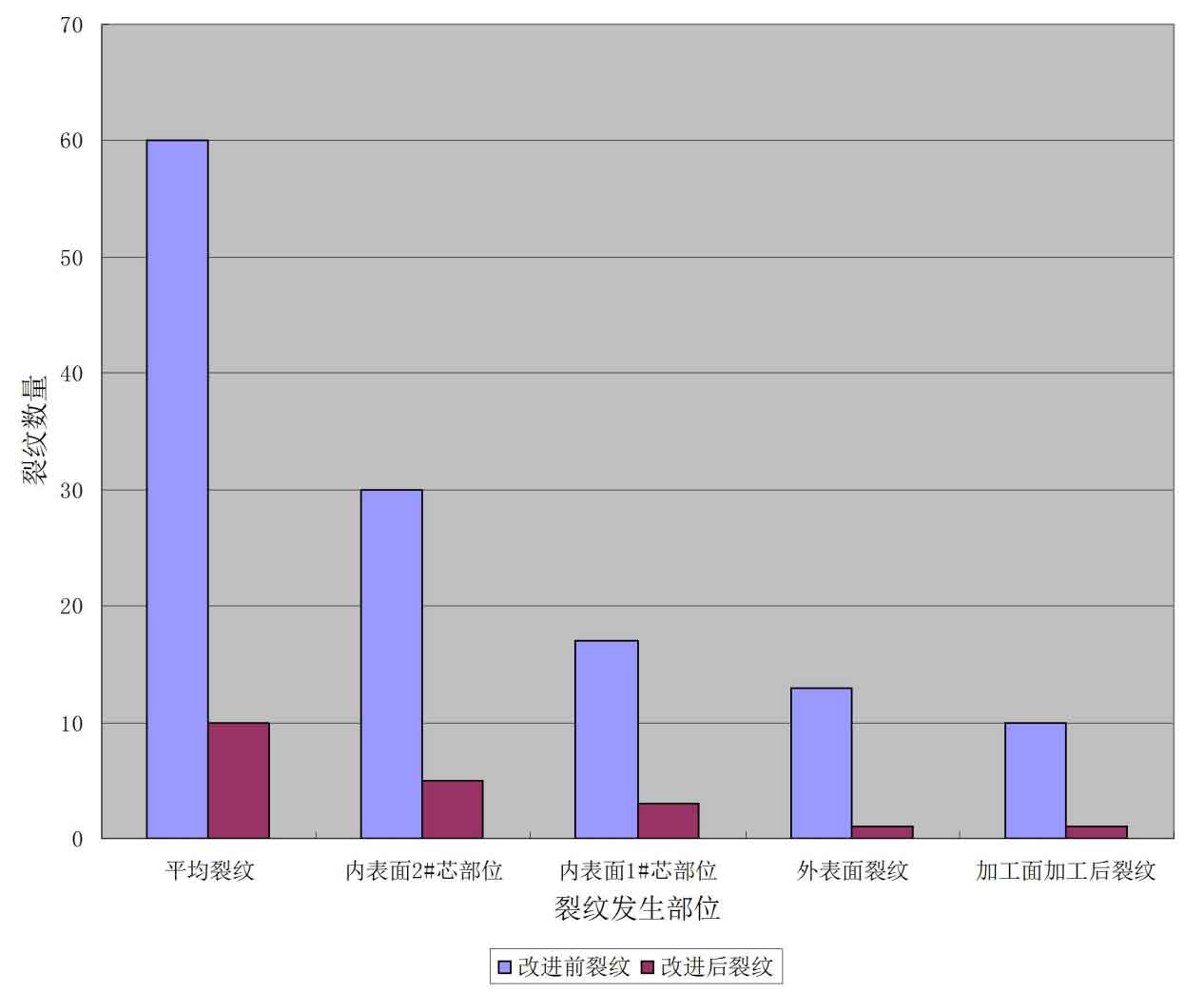

1.Crack improvement

Before the implementation of the new sand mold casting process, the average number of cracks in each shell steel casting is 60, 10 cracks on the outer surface of the sand mold casting, 15 cracks on the inner surface 1# core, 32 cracks on the inner surface 2# core, and 10 cracks after machining. Some cracks are open cracks, with a depth of 10-15mm. The cracks detected are shallow and the deepest ones are 10mm. After the implementation of the new sand casting process, the average number of cracks in each shell steel casting is 10, including 1 crack on the outer surface of the sand casting, 3 cracks on the inner surface 1# core, 5 cracks on the inner surface 2# core and 1 flaw detection crack on the machined surface. There is no open crack. The flaw detection crack is 1.5mm shallow and 5mm deepest. The crack distribution before and after improvement is shown in Figure 5.1. It can be clearly observed from Figure 1 that the number of cracks is significantly reduced.

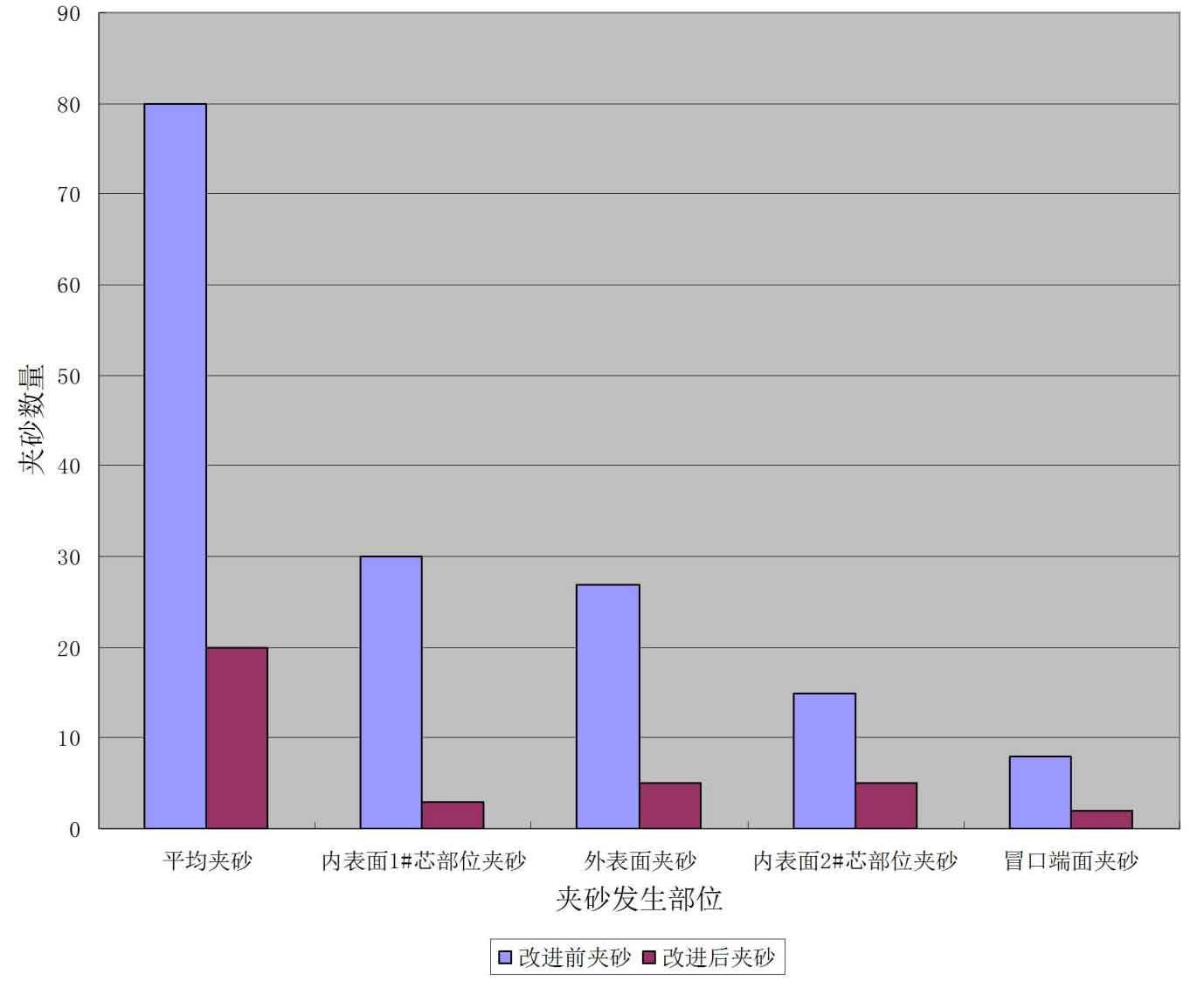

2. Improvement of sand inclusion defects

Before the implementation of the new sand mold casting process, the average number of sand inclusions in each shell steel casting is 80 points, 27 points on the outer surface of the sand mold casting, 30 points on the inner surface 1# core, 15 points on the inner surface 2# core and 8 points on the end face of the riser. The sand inclusion defects are mainly dispersed. After the implementation of the new sand casting process, the average number of sand inclusions in each shell steel casting is 20 points, including 5 points on the outer surface of the sand casting, 3 points on the inner surface 1# core, 5 points on the inner surface 2# core and 2 points on the end face of the riser. The diameter of sand inclusions shall not exceed 3mm. See Figure 5.2 for sand inclusion before and after improvement. It can be clearly seen from Figure 2 that the number of sand inclusion defects has been greatly reduced.