Sand casting product is a kind of defective product. At present, no company at home and abroad can make sand casting without any defects. The steel castings of the shell casting are supplied as blanks, and then assembled after processing in the customer’s company. After assembly, the parts are processed. Because the processing area is relatively large, accounting for about 1 / 2 of the internal and external surface area, the probability of exposed defects of shell casting steel castings is high, and the quality risk of shell casting steel castings is very high.

From January 2020 to March 2020, ZHY casting supplied 160 shell casting steel castings to foreign customers. 10 shell casting steel castings were fed back that the processing surface had exposed cracks and sand inclusion defects. One of them found serious cracks during processing after assembly, which was directly reported to be discarded by the customer, with a loss of 100000 yuan. In addition, if the major internal defects of the shell steel castings are not found, the driving safety accident will be caused after loading and use, and the loss to the company will be immeasurable. After the implementation of the new sand mold casting process, a total of 2760 pieces were supplied to customers from April 2020 to December 2020, of which 37 pieces were fed back by customers that there were outcrop defects on the processing surface, but the defects were within the repairable range and there were no scrapped products.

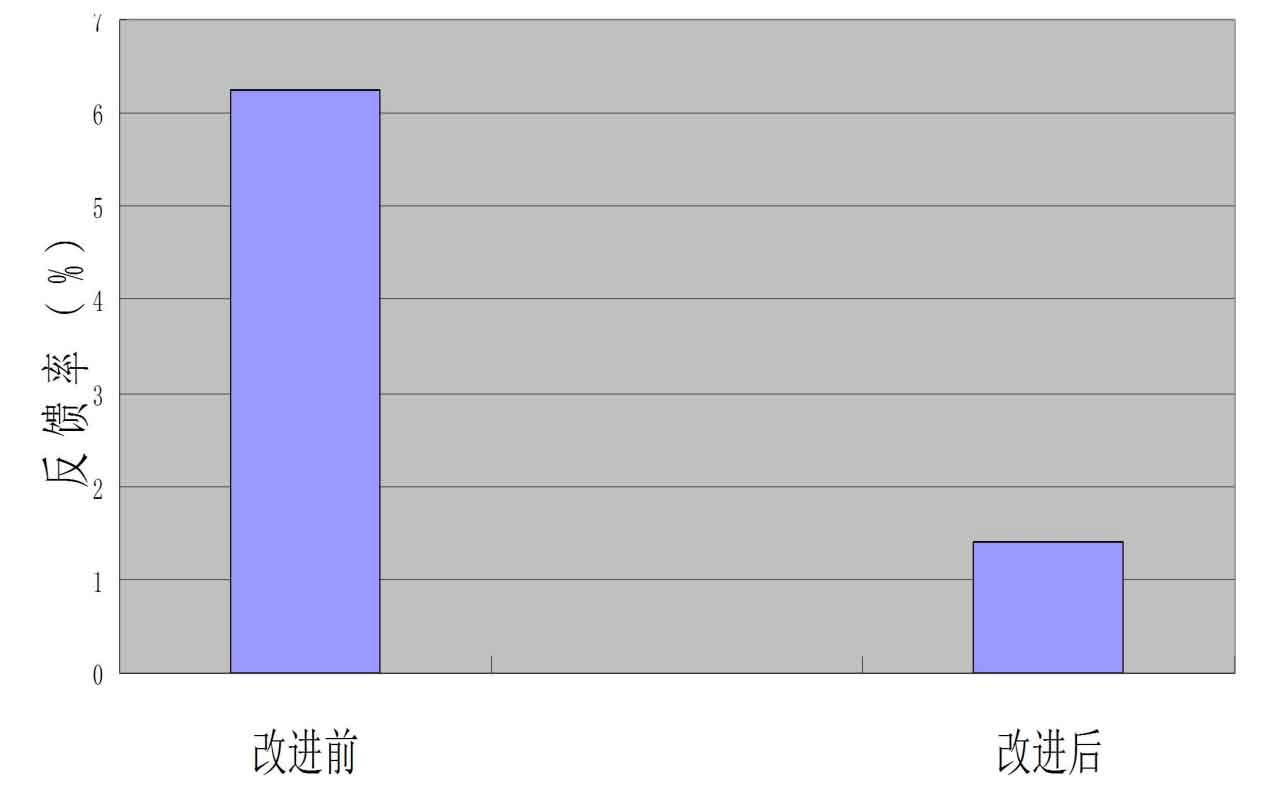

After the overall improvement of the quality of shell steel castings, the quality risk and feedback rate of shell steel castings decreased significantly, and the feedback rate was 2% lower than the quality feedback target set by the customer to the company. See figure for quality feedback.