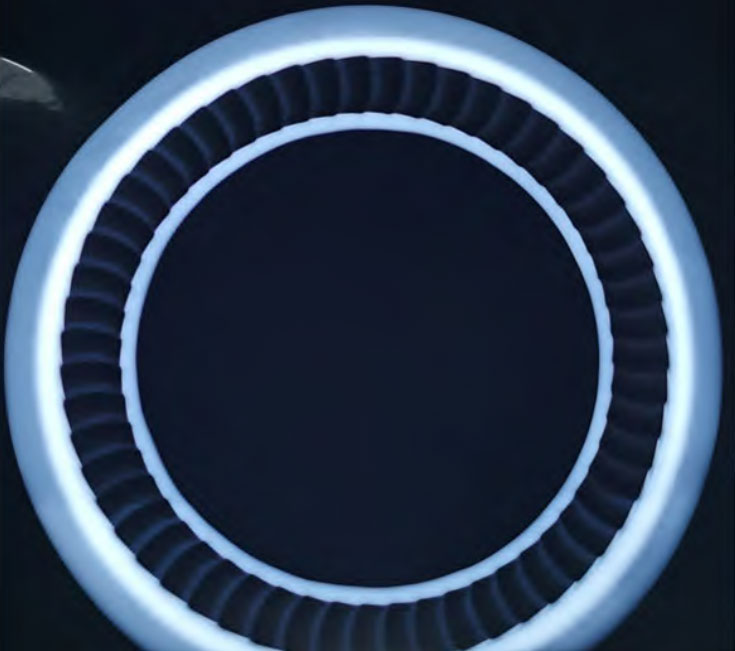

Based on the optimized precision casting process plan for the turbine guide, conduct the first batch of 10 production validation and product trial production. Using an X-ray machine with the model ISOVOLT320 HS and in accordance with the operational requirements of ASTME1742 radiographic inspection standard, metallurgical quality testing was conducted on all test pieces. The results met the inspection requirements for cracks, pores, shrinkage porosity, inclusions, and other defects in standard EMS52301/2. The results are shown in the figure.

Afterwards, the precision casting process plan was used for small-scale production of 50 pieces, and its metallurgical quality and testing results met the requirements. This not only verified the accuracy of numerical simulation results and analysis, but also proved the reliability of this precision casting process plan.