1.Mold making and trial production

According to the designed process drawing and tooling drawing, the die quotation is carried out. Finally, the mold is manufactured by the outsourcing mold manufacturer. The product mould is shown in Figure 1. The enterprise model technicians checked the mould made by external cooperation and confirmed that the dimension of the mould is qualified and consistent with the product drawing, process drawing and tooling drawing.

After confirming that the mold is qualified, the trial production is carried out. Figure 2 shows the photo of the gas cutting riser of the product.

2.Radiographic inspection and result confirmation

After cleaning, normalizing, modulating heat treatment, inspection and other processes, the size and appearance of product k141 can meet the needs of customers. In order to confirm the internal quality, send the products to the outsourcing unit for radiographic inspection. Radiographic inspection shows that there are shrinkage cavity and porosity defects inside the product, and the defect level is higher than jisg05813 standard. Figures 3, 4, 5 and 6 show the photos of the divided areas of radiographic inspection products.

The results of radiographic inspection are shown in the table, and a total of 18 radiographic inspection are unqualified. Carry out air gouging on the defective parts and draw the conclusion:

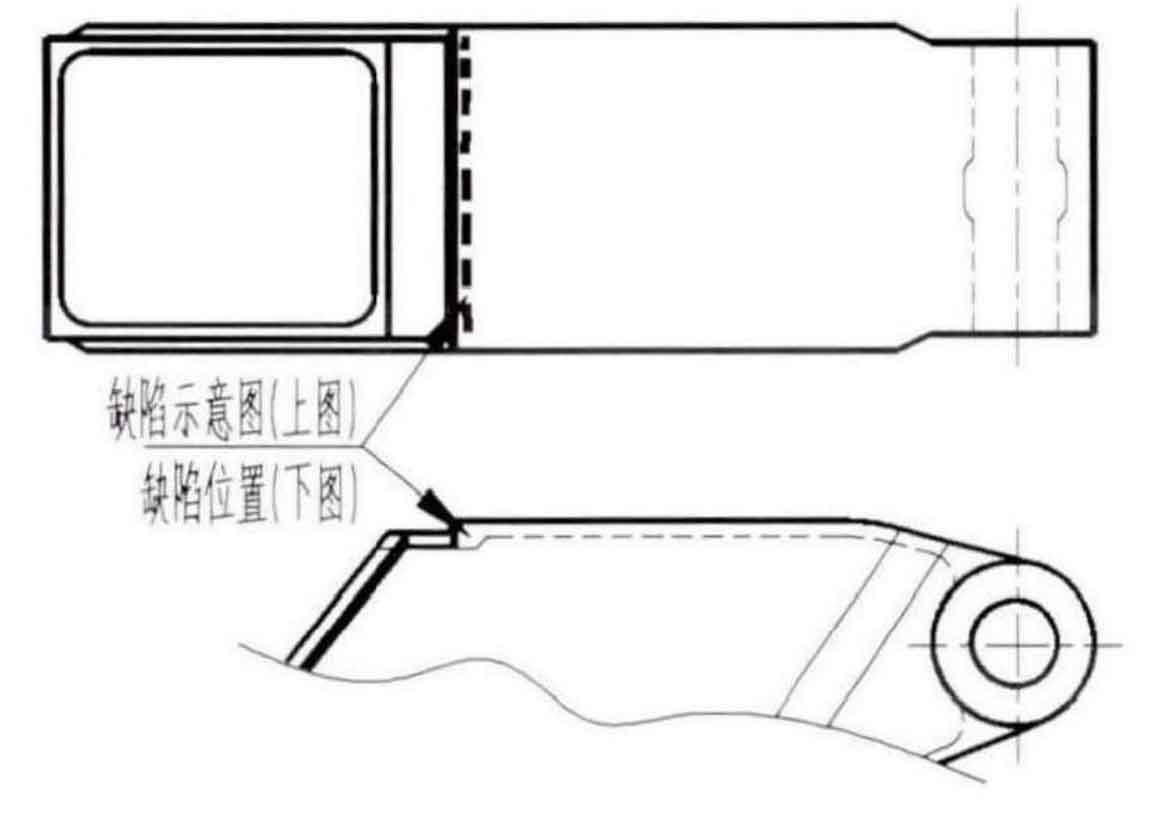

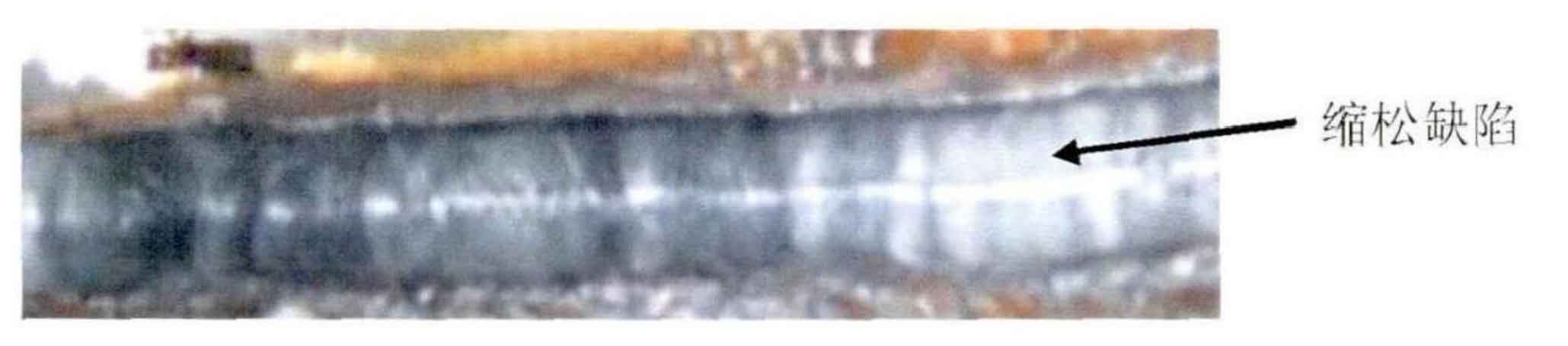

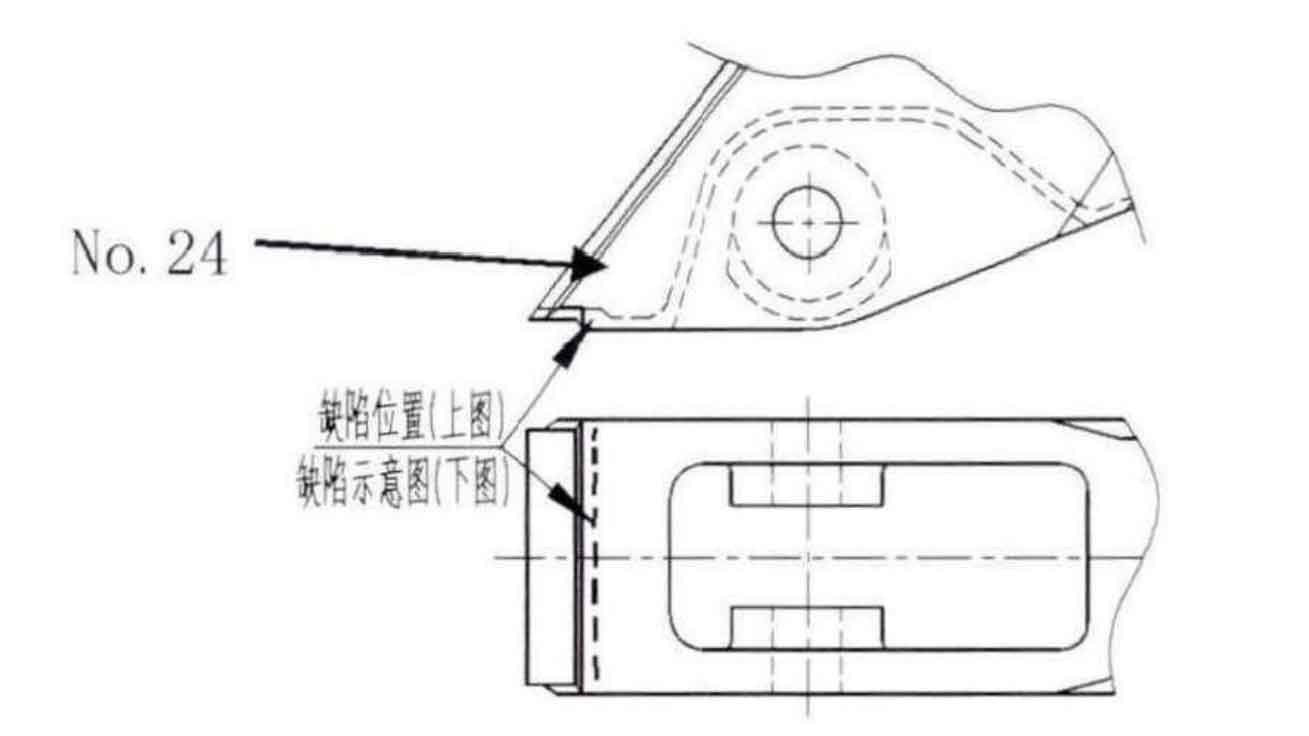

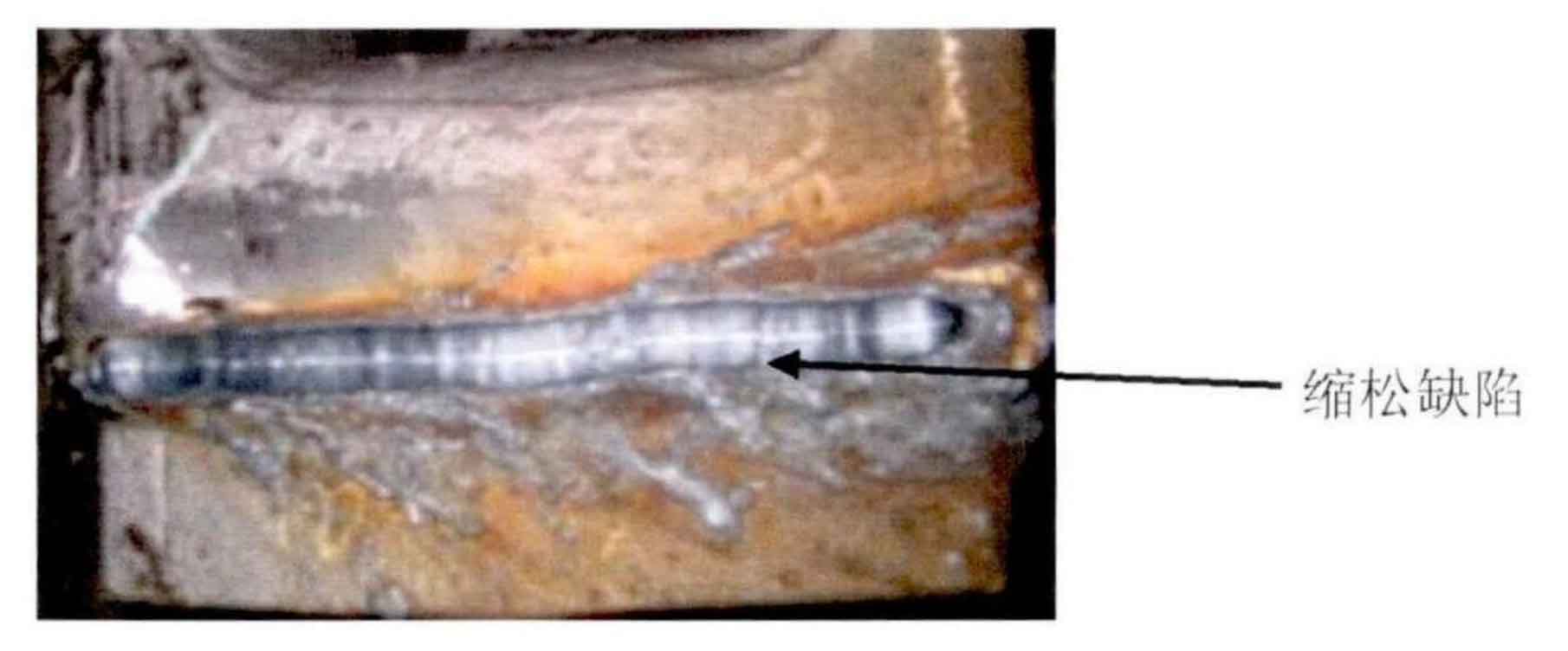

(1) The displayed defect is a continuous linear shrinkage, marked as I, the position is shown in Figure 7, and the appearance of the defect is shown in Figure 8.

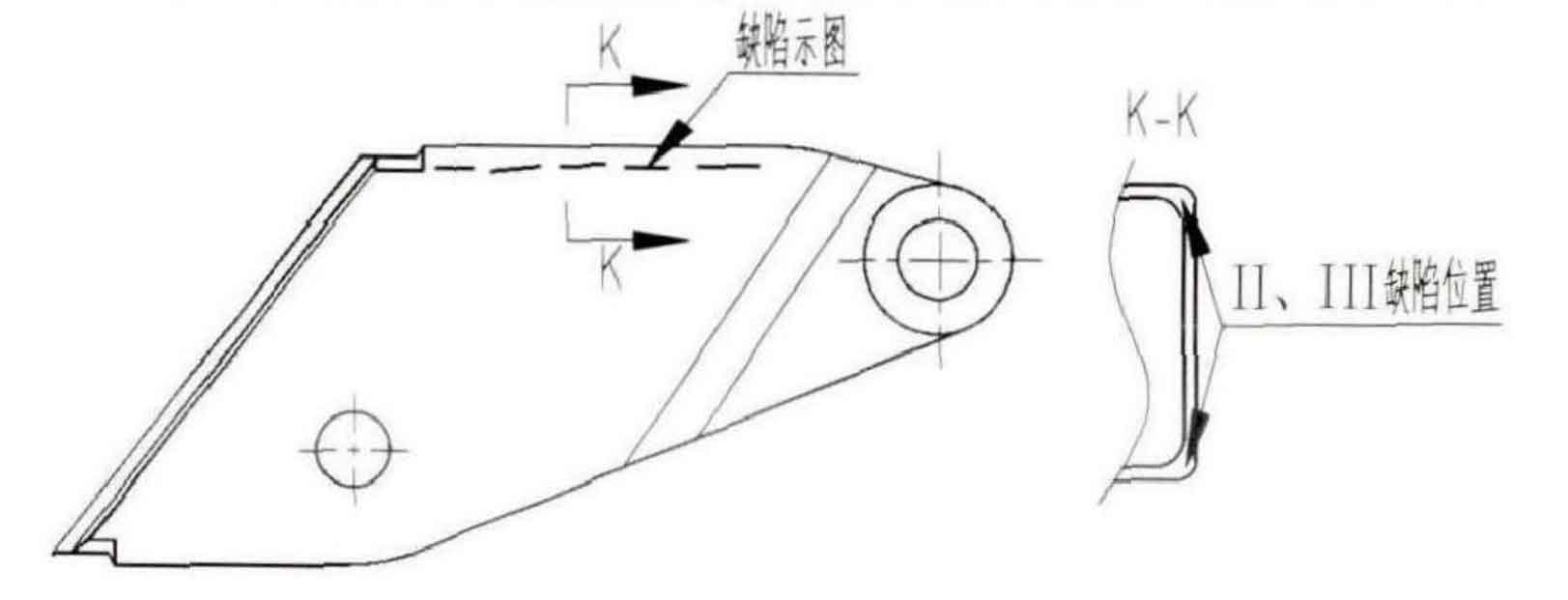

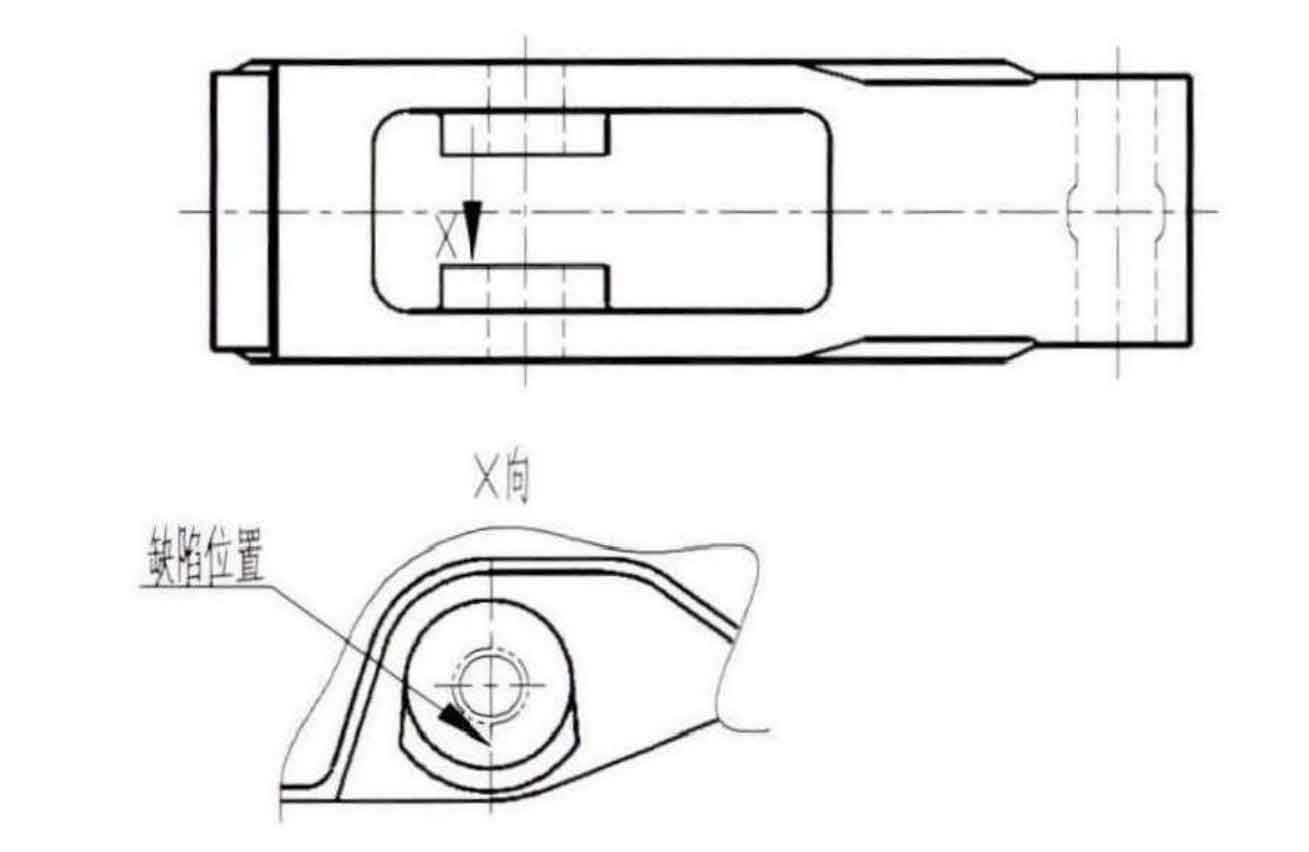

(2) The displayed defects are two continuous linear shrinkage porosity. The defects on the upper type side are marked as II and the defects on the lower type side are marked as III. the position is shown in Figure 9 and the appearance of the defects is shown in Figure 10.

(3) The displayed defect is a continuous linear shrinkage, marked as IV, the position is shown in Figure 11, and the appearance defect is shown in Figure 12. Corresponding to the triangular area in the figure, the current shrinkage porosity extends upward close to the top of the casting.

(4) The displayed defect is a shrinkage cavity marked with V, the position is shown in Figure 13, and the appearance defect is shown in Figure 14.