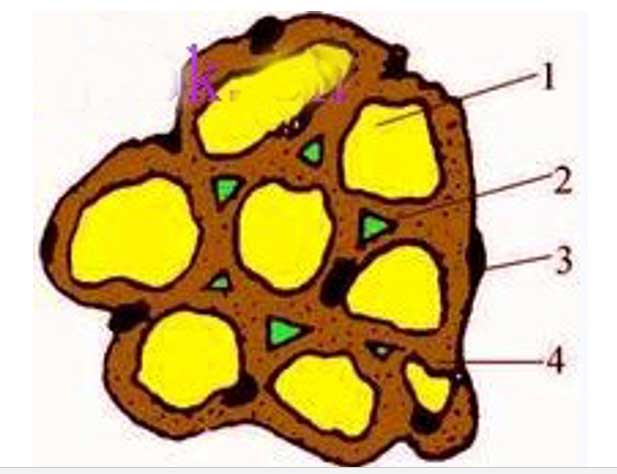

The material used to make sand mold is called molding material, the material used to make sand mold is called molding sand, and the molding material used to make sand core is called core sand. Generally, molding sand is composed of original sand (mountain sand or river sand), clay and water in a certain proportion, of which clay is about 9%, water is about 6%, and the rest is original sand. Sometimes a small amount of additives such as coal powder, vegetable oil and wood chips are added to improve the performance of molding sand and core sand. The compacted sand structure is shown in the figure.

The quality of molding sand and core sand has a direct impact on the quality of castings. If the quality of molding sand is not good, defects such as porosity, sand hole, sand sticking and sand inclusion will occur in castings. Good molding sand shall have the following properties:

1) Breathable type

When the high temperature liquid metal is poured into the mold, the mold is filled with a lot of gas, which must be discharged smoothly from the mold. The property of molding sand that can let the gas through is called permeability. Otherwise, defects such as porosity and insufficient pouring will occur in the casting. The permeability of the mold is affected by the grain size, clay content, moisture content and the compactness of the sand mold. The finer the grain size of sand, the higher the clay and moisture content, the higher the compactness of sand mold, the worse the permeability

2) strength

The ability of molding sand to resist external forces is called strength. Molding sand must have enough high strength to avoid collapse in the process of molding, handling and closing, and to avoid damaging the surface of the mold during pouring. The strength of molding sand should not be too high, otherwise the casting will have defects due to the decrease of air permeability and backwardness. 3) fire resistance

High temperature liquid metal has a strong thermal effect on the mold after pouring, so the molding sand should have the ability to resist the high temperature thermal effect, that is, fire resistance. If the fire resistance of molding material is poor, the casting is easy to produce sand sticking. The more SiO2 content in molding sand, the larger molding sand particles, the better fire resistance.

4) plasticity

It refers to the ability of molding sand to deform under the action of external force and keep the existing shape completely after removing the external force. The molding material has good plasticity, convenient operation, accurate shape and clear outline.

5) concession

When the casting condenses, the volume shrinks, and the molding sand should have a certain capacity of being compressed, which is called the concession. Because of the poor yield of molding sand, castings are prone to internal stress or cracking. The more compact the molding sand, the worse the yielding. Adding sawdust and other materials to molding sand can improve the yield.