Structural steel after quenching and high temperature tempering has good comprehensive mechanical properties, high strength, good plasticity and toughness. The steel suitable for this heat treatment is called quenched and tempered steel. The strength of quenched and tempered steel mainly depends on α Phase strength and carbide dispersion strengthening. Alloy elements silicon, manganese and nickel are soluble in α Phase, playing the role of solid solution strengthening. The mass fraction of carbon in steel is between 0.3%-0.5%, which can ensure that there is enough carbide volume fraction to obtain high strength. Alloy elements such as chromium, molybdenum, tungsten and vanadium can prevent the aggregation and growth of carbides during high temperature tempering and maintain the high strength of steel. Chromium, molybdenum, tungsten and vanadium also hinder α The recrystallization of phase can maintain the fine crystal block structure and make α The phase can also maintain high enough strength. If quenched and tempered steels with different chemical compositions are quenched to obtain martensite and tempered to the same tensile strength, similar σ s、 δ and φ。 This means that quenched and tempered steels with different compositions can be interchanged as long as their hardened parts are equivalent.

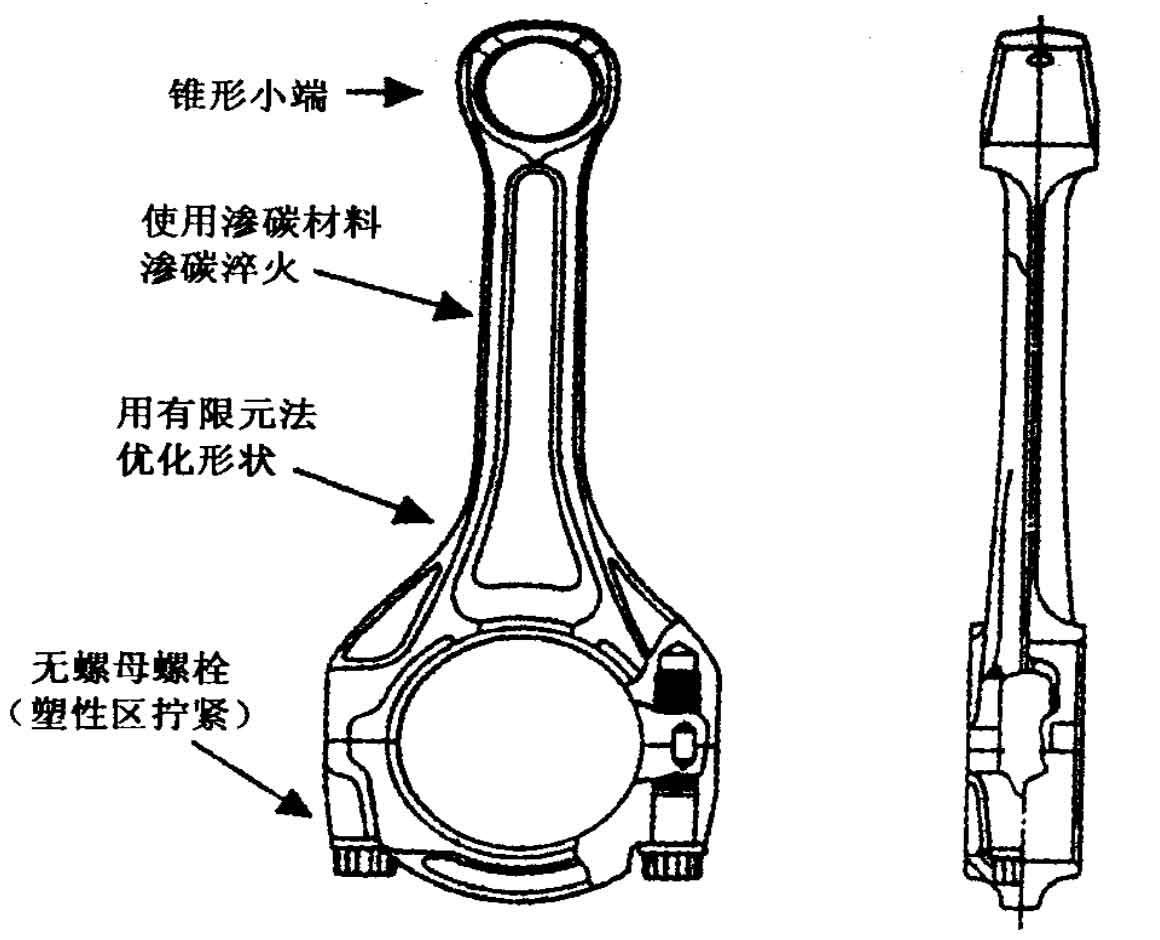

Quenching and tempering is a process that combines quenching with high temperature tempering in order to obtain certain strength and toughness. Quenching and tempering can adjust the properties and materials of steel to a great extent. It has good strength, plasticity and toughness, and has good comprehensive mechanical properties. Quenching and tempering treatment is widely used in various important structural parts, especially those connecting rods, bolts, gears and shafts working under alternating load. In the past, the commonly used materials for automobile connecting rods were selected medium carbon steel and medium carbon alloy steel with carbon content, which must be subject to quenching and tempering treatment to obtain ideal structure and properties. After quenching and tempering treatment, tempered sorbite structure can be obtained, and its mechanical properties are better than normalized sorbite structure with the same hardness. Its hardness depends on the high temperature tempering temperature and is related to the tempering stability of the steel and the section size of the workpiece, generally between hb200-350. The automobile connecting rod is generally made of high-quality medium carbon structural steel or alloy structural steel with selected carbon content, which needs to be quenched and tempered to meet the design technical conditions, so as to obtain ideal stable structure and performance. Therefore, this kind of connecting rod is called quenched and tempered steel connecting rod.