Traditional pattern-based casting methods often fail to meet the short-cycle and low-cost demands of small-batch production for tractor components like internal/external lift arms, transmission rods, and brake housings. This study develops a rapid sand casting methodology integrating digital design, simulation, and patternless manufacturing to address these challenges.

1. Rapid Casting Process Architecture

The optimized process flow integrates digital technologies with conventional foundry operations (Figure 2 schematic):

$$ \text{CAD Design} \rightarrow \text{CAE Simulation} \rightarrow \text{Sand Mold Machining} \rightarrow \text{Assembly} \rightarrow \text{Pouring} \rightarrow \text{Finishing} $$

Critical process parameters include:

- Mold material selection based on complexity

- Batch size optimization (typically 2-20 pieces)

- Sand block dimensions: 1000 × 1000 × 300 mm (minimum 50 mm mold wall thickness)

2. Material Formulation & Sand Preparation

Material composition directly impacts mold strength and surface finish. Verified formulations include:

| Material | Composition | Setting Time | Tensile Strength (MPa) |

|---|---|---|---|

| Water Glass Sand | 94-95% silica sand (50/100 mesh) 5-6% sodium silicate |

24 hr CO₂ curing | 1.0 ± 0.2 |

| Phenolic Resin Sand | 98% silica sand 1% CPI-1600 resin 1% CPII-2600 resin 1-6% CPIII-3595/3550 hardener |

24 hr ambient cure | 3.6 ± 0.3 |

The strength-development equation for resin-bonded sand follows:

$$ \sigma_t = K \cdot e^{(R/T)} \cdot t^n $$

Where \(\sigma_t\) = strength at time t, K = material constant, R = activation energy, T = temperature, n = time exponent.

3. Digital Manufacturing Methodology

Patternless CNC machining enables direct conversion of CAD models into functional molds:

| Operation | Tool Type | Spindle Speed (rpm) | Feed Rate (mm/min) | Depth of Cut (mm) |

|---|---|---|---|---|

| Roughing | M16 Cavity Mill | 3,500 | 2,400 | 5.0 |

| Semi-Finishing | M8 Rest Mill | 5,000 | 1,800 | 2.0 |

| Finishing | B6 Z-Level | 8,000 | 1,200 | 0.5 |

Toolpath optimization reduces machining time by 40% through:

$$ T_m = \frac{V_m}{MRR} + T_{rapid} $$

Where \(T_m\) = machining time, \(V_m\) = material volume, MRR = material removal rate, \(T_{rapid}\) = non-cutting time.

4. Casting Process Validation

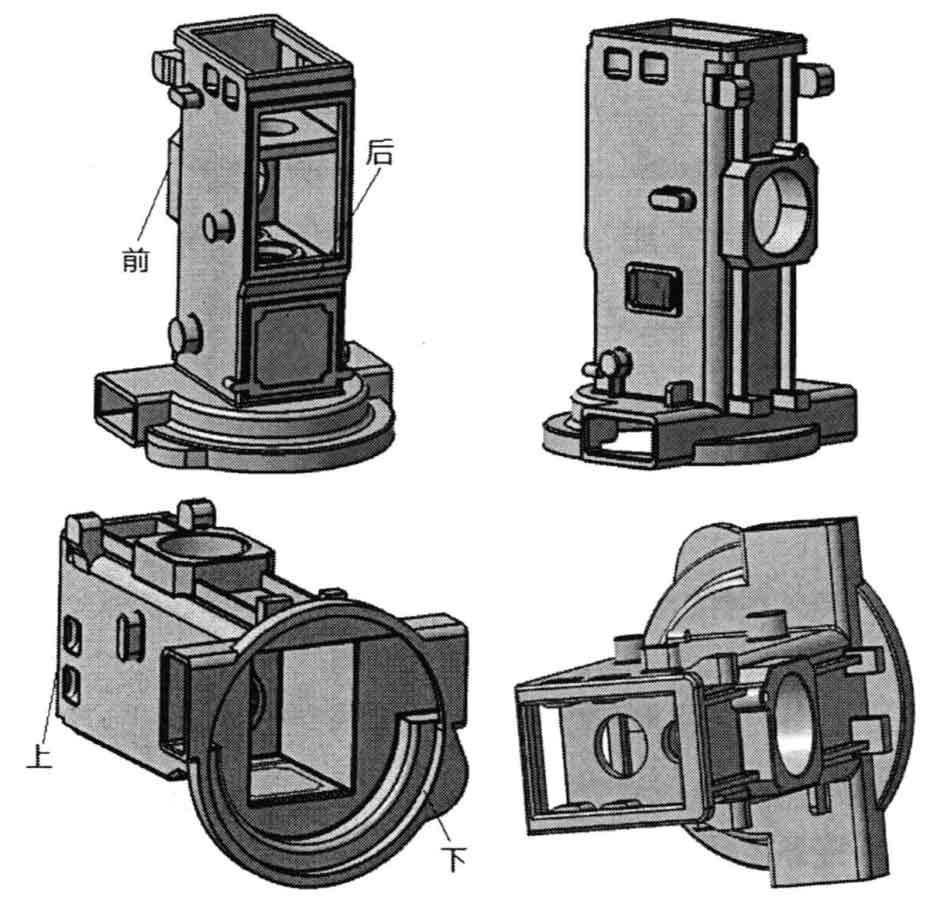

Two critical tractor components were selected for validation:

| Component | Method | Cycle Time (days) | Cost (USD) | Surface Roughness (Ra μm) | Dimensional Tolerance |

|---|---|---|---|---|---|

| Brake Lever (ZG45) 0.85 kg |

Traditional | 30 | 580 | 25-50 | CT10 |

| Rapid | 2 | 140 | 25 | CT10 | |

| Distributor Housing (ZG45) 4.7 kg |

Traditional | 30 | 760 | 25-50 | CT10 |

| Rapid | 4 | 210 | 25 | CT10 |

The gating design for multi-cavity molds follows fluid dynamics principles:

$$ v = C_v \sqrt{2gh} $$

$$ Q = A \cdot v $$

Where v = flow velocity, \(C_v\) = velocity coefficient, g = gravity, h = metallostatic head, Q = flow rate, A = choke area.

5. Metallurgical Quality Control

Component testing confirmed mechanical properties met ASTM standards:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|

| ZG45 Specification | ≥450 | ≥250 | ≥18 | 140-200 |

| Brake Lever | 480 | 270 | 20 | 165 |

| Distributor Housing | 475 | 265 | 19 | 170 |

6. Economic Impact Analysis

The rapid tractor casting method demonstrates significant advantages for small-batch production:

$$ \text{Cost Savings} = \left(1 – \frac{C_r}{C_t}\right) \times 100\% = \left(1 – \frac{140}{580}\right) \times 100\% = 76\% $$

$$ \text{Time Reduction} = \left(1 – \frac{T_r}{T_t}\right) \times 100\% = \left(1 – \frac{2}{30}\right) \times 100\% = 93\% $$

Break-even analysis confirms viability for batch sizes under 50 pieces:

$$ Q_b = \frac{F_c}{P_v – V_c} $$

Where \(Q_b\) = break-even quantity, \(F_c\) = fixed pattern costs, \(P_v\) = value per casting, \(V_c\) = variable cost per unit.

7. Conclusion

This rapid tractor casting methodology demonstrates:

- 85% average reduction in lead time compared to traditional pattern making

- 72-76% cost reduction for small-batch tractor component production

- Consistent achievement of CT10 dimensional accuracy and Ra 25 μm surface finish

- Successful application for critical tractor components like brake systems and transmission housings

The integration of digital manufacturing with conventional foundry practice creates a responsive production system for low-volume tractor casting requirements, particularly valuable during product development and prototype validation phases.