When high chromium cast iron is as cast, its matrix structure is austenite. The austenitic structure has good plastic toughness, low hardness, weak ability to provide protection for carbides and poor wear resistance, which can not meet the industrial demand. Therefore, as cast high chromium cast iron needs further heat treatment to improve its properties.

The matrix structure of high chromium cast iron after heat treatment is martensite + retained austenite. The residual austenite has strong plastic deformation, which can improve the toughness of high chromium cast iron to a certain extent, and produce work hardening during wear processing, so as to provide good support for carbides, passivate the crack tip and inhibit the crack propagation. High hardness martensite matrix can support and wrap carbides to protect the matrix. However, martensitic matrix does not have enough plastic deformation ability, so it can not effectively resist crack propagation. Therefore, when the wear force is high, the wear surface with martensite as the matrix structure is easy to peel off, that is, the surface roughness is high.

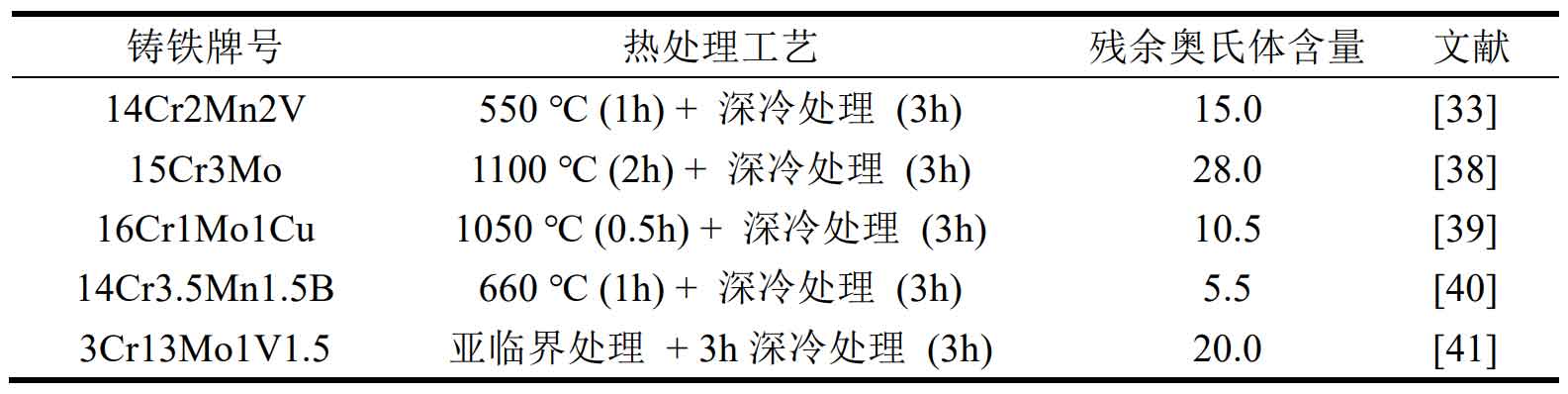

It is found that when the content of martensite in the matrix is too high or full martensite, the surface of the matrix is easy to be broken and the wear resistance is poor; When the matrix structure is retained austenite + martensite, high chromium cast iron has better wear resistance; When the matrix is full martensite, the wear resistance is the worst. The table shows the content of retained austenite in the corresponding matrix structure when the wear resistance of cast iron with different components is the best.