Due to the high pouring temperature of steel castings, in order to improve the heat resistance of coated sand, special coated sand made of zirconium sand is widely used in practical production. However, zirconium sand is expensive and needs to be imported, and scar casting defects will appear on the local surface of steel castings produced by zirconium sand coated sand, which seriously affects the surface forming quality of steel castings. A new type of high temperature resistant coated sand with quartz sand as the main component has been proposed.

| Normal temperature tensile strength / MPa | High temperature tensile strength / MPa | Heat resistance time / S | Softening point | Si2O content |

| 2.0~2.4 | 4~5 | 155 | 91-95 | ≥98% |

The coated sand can improve its high temperature performance by changing the properties of phenolic resin; By adding some special components, the speed of resin decomposition and heat dissipation are reduced, and the fluidity and stability of coated sand are effectively improved. Some manufacturers have used this high-temperature steel casting coated sand to produce high-precision complex structural steel castings, and the production speed and single piece profit margin have been greatly improved, and good economic benefits have been achieved. This kind of coated sand has superior performance, and the specific technical parameters are shown in the table. Based on the above reasons, this quartz sand based high temperature resistant cast steel coated sand is selected to produce spiral bevel gear castings.

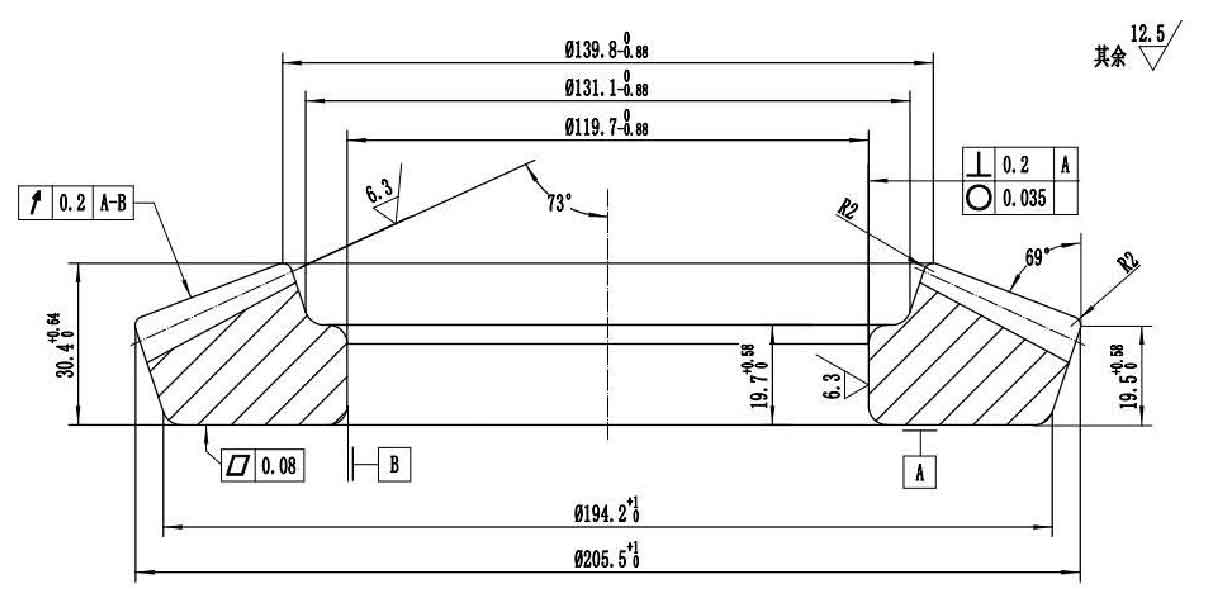

According to the relevant provisions of 1999-gb / t6414, the dimensional tolerance of steel castings produced by coated sand casting process can reach cT4 ~ 6. Due to the existence of tooth shape and complex geometric conditions, the casting drawing of spiral bevel gear blank casting is obtained by comprehensively considering the factors such as casting shrinkage of material, mold starting inclination, process correction and subsequent forging process.