Based on the previous experience of investment casting and sand casting in the production of various impellers, the two commonly used casting process schemes are studied and compared. Finally, the top injection process scheme II with horizontal parting, three feeding risers in the rim part and one riser with gate in the hub part is selected.

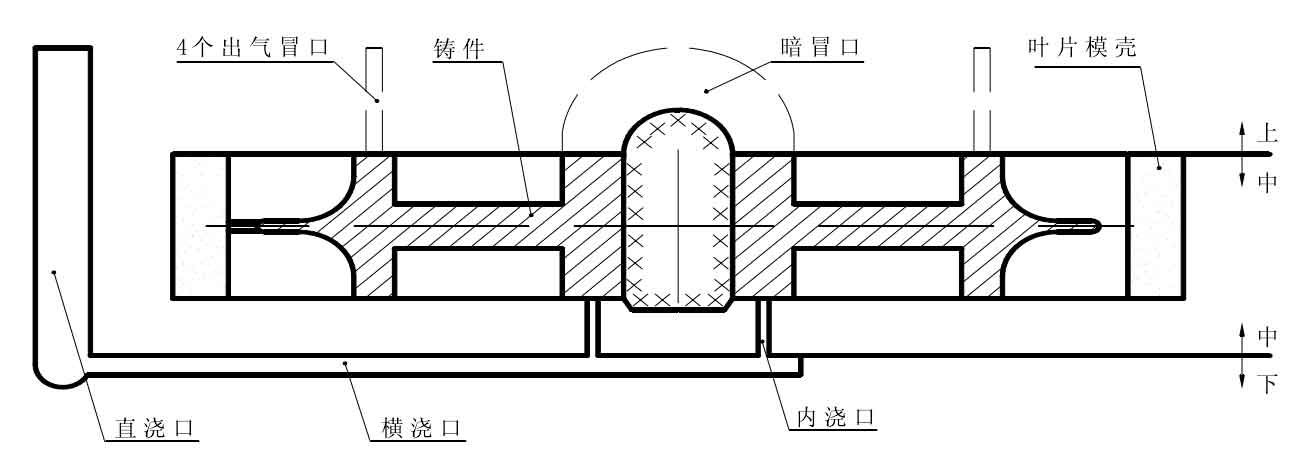

a. Design scheme I

As shown in Figure 1. The process is three box modeling, the whole appearance and core adopt sodium silicate sand, and the blade part adopts the composite modeling process of ethyl silicate sodium silicate molten shell. The bottom return gating system is adopted, the hub is fed with a concealed riser, and only four are set on the rim Ф Process scheme I for placing filter screen at the outlet riser, straight sprue and transverse sprue of 20.

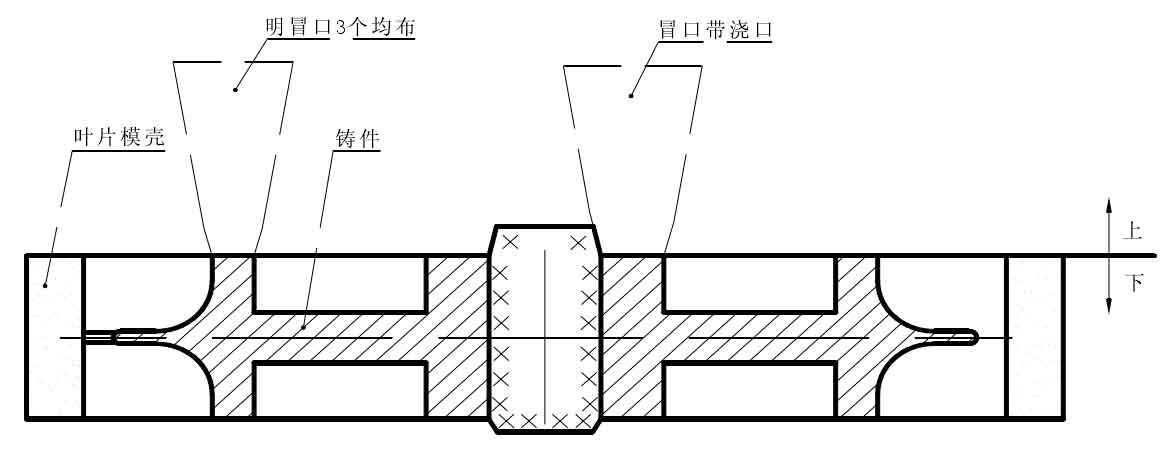

b. Design scheme II

As shown in Figure 2. This process is two box molding, and the whole mold is also composed of sodium silicate sand and ethyl silicate sodium silicate composite molten shell. The rim part is provided with three open risers for feeding and exhaust, and the hub part is provided with a riser through which the impeller is poured. The process scheme II of horizontal parting and top injection is adopted.

c. Comparison of process schemes

Scheme 1: because the thickness of impeller blade is only 5mm and the material is zg1cr18ni9ti. Due to the bottom return gating system, the process not only increases the difficulty of modeling, but also leads to slow filling of liquid metal, easy oxidation of liquid metal, and defects such as cold shut and insufficient pouring in the blade due to the long transverse runner. Although the blade has a certain cooling effect on the rim, due to the large shrinkage rate of zg1cr18ni9ti body, only four outlet risers are set at the hot section of the rim, which is prone to shrinkage cavity, shrinkage porosity and other defects. Therefore, design scheme I can not ensure the technical requirements of the casting.

Scheme 2: the top injection process of riser with gate ensures the rapid filling of zg1cr18ni9ti molten steel, which is conducive to the feeding of hot joints and avoids the generation of shrinkage cavity and porosity at the hot joints of hub and rim. At the same time, because it is a two box shape and adopts the overall shape shape, the shape is simple, the shape is simple, the technical requirements for operators are low, and it is easy to ensure the matching accuracy between the mold shell and the mold when closing the box. Although the top injection process is prone to sand inclusion, pores and other defects, considering that the impeller height is only 130mm and the splash is small, the shortcomings of the process can be overcome by selecting reasonable pouring methods, placing three riser feeding belts on the rim for exhaust, forming air holes on the blade, melting high-quality molten steel and other process measures. Based on comprehensive consideration, process scheme II is selected.