After any liquid metal is injected into the mold, it goes through three interrelated shrinkage stages from pouring temperature to normal temperature. These three stages are liquid shrinkage stage, solidification shrinkage stage and solid shrinkage stage. The liquid shrinkage stage refers to the cooling from pouring humidity to liquidus temperature; Solidification shrinkage stage refers to the cooling from liquidus temperature to solidus temperature (including the change of state); The solid state shrinkage stage refers to cooling from the solidus temperature to normal temperature.

In the solid-state shrinkage stage, the size of the outlet line is reduced in all directions of the sand casting, which has the greatest impact on the shape and dimensional accuracy of the sand casting, which is the basic reason for the stress, deformation and crack of the sand casting. Linear shrinkage is commonly used to represent solid-state shrinkage.

The actual shrinkage of sand castings not only needs to consider the influence of metal composition, temperature and phase transformation, but also the influence of external resistance. When the shrinkage of sand castings in the mold is only affected by the friction resistance between the metal surface and the mold surface, it is free shrinkage. If there are other obstacles to the shrinkage of sand castings in the mold, it is called hindered shrinkage. For the same alloy, the hindered shrinkage is less than the free shrinkage.

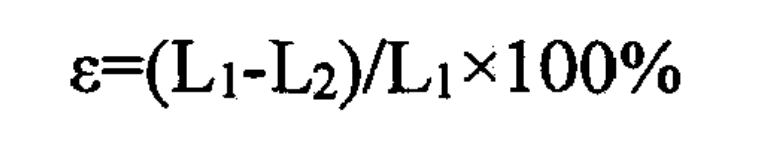

Linear shrinkage rate of sand casting, also known as shrinkage rate of sand casting or shrinkage rate of sand casting, refers to the relative linear shrinkage rate of sand casting when the temperature of sand casting cools to room temperature from the beginning of linear shrinkage, which is expressed by the length difference between pattern and sand casting divided by the percentage of pattern length;

Where: L1 – pattern length; L2 – casting length; ε— Linear shrinkage of castings.

The linear shrinkage rate of sand casting is the actual shrinkage rate of sand casting after considering various influencing factors. It is not only related to the shrinkage rate of sand casting metal and the initial temperature of linear shrinkage, but also related to the structure of sand casting, the type of mold, the structure of gating and riser system, the concession of sand mold and sand core and so on.

Product k141 adopts alkali phenolic resin sand process and lead mold. The production line is an automatic production line. Through experience, the shrinkage rate of sand castings of this production process is set at 1.9%. If the local shrinkage changes, it will be solved by increasing the process correction.