With the continuous improvement of the quality requirements of diesel engine products in the whole machine factory, higher and higher requirements are put forward for castings. In order to meet the needs of the market, high-grade gray cast iron is currently used to produce cylinder heads. The domestic high-grade gray cast iron cylinder head has a large shrinkage tendency due to low carbon equivalent and large amount of alloy addition, which leads to the increase of water leakage rate of the cylinder head and seriously affects the batch production of the cylinder head.

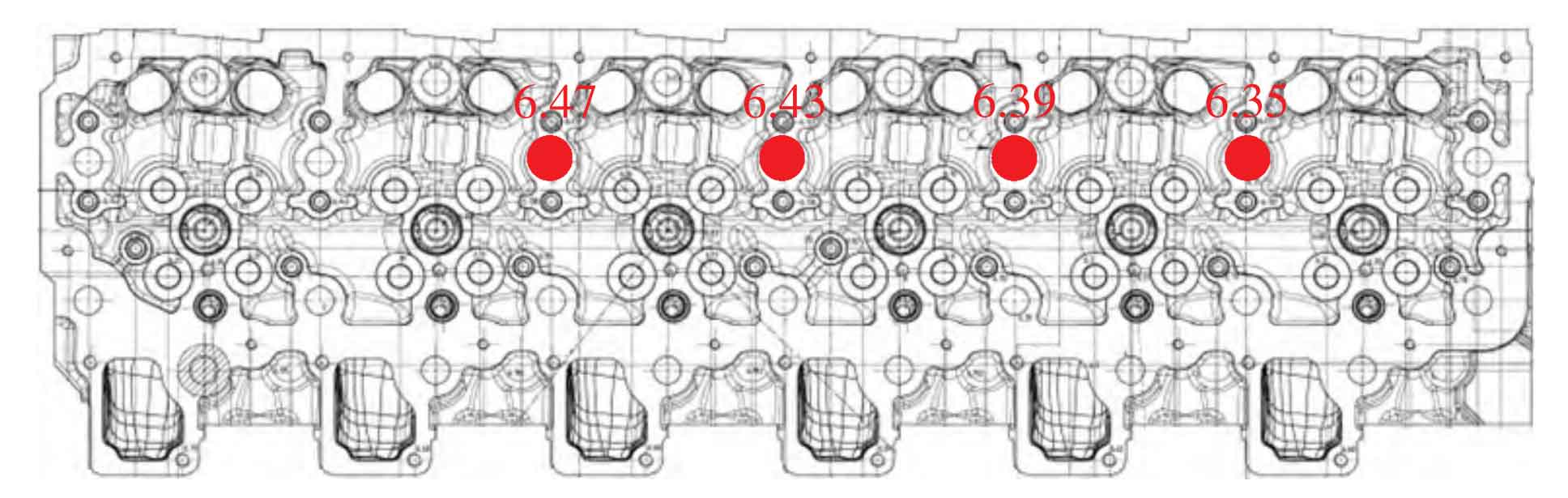

The high-grade gray cast iron cylinder head of large diesel engine is a 6-cylinder 4-Valve cylinder head with material grade ht350. The casting blank weight is 90 kg, the main wall thickness (also the minimum wall thickness) is 5 mm, and its inlet and exhaust channels are on one side.

(1) Placing an external chill at the hot joint of the gray cast iron cylinder head can solve the shrinkage of this part, but it leads to the transfer of shrinkage between multiple hot joints in the cylinder head.

(2) The effect of placing internal chill at the hot joint of high-grade gray cast iron of large diesel engines is stronger than that of external chill, which can effectively reduce the scrap rate.

(3) The combined use of internal and external chills at the hot spot is better than the use of internal or external chills alone.