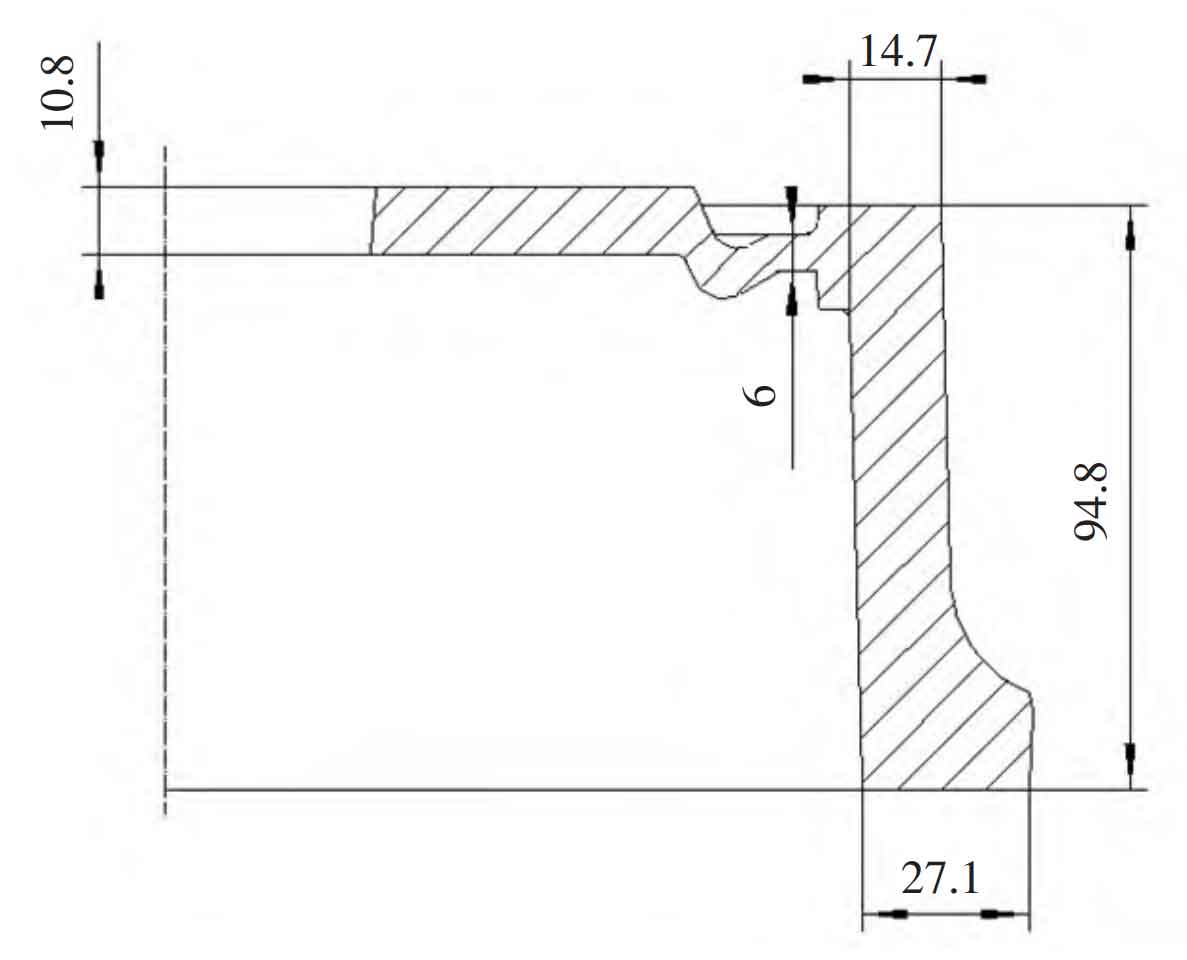

A certain type of gray cast iron brake drum produced by ZHY casting has a casting weight of 6kg, a main wall thickness of 14.7mm, a maximum wall thickness of 27.1mm and a minimum wall thickness of 6mm. The structure and dimensions of the casting are shown in the figure. The casting has shrinkage defects after machining, resulting in the scrapping of this batch of semi-finished products.

(1) The glass transition temperature of phenolic urethane resin is 78.52 ℃, and the rigidity of the resin decreases rapidly from room temperature to 78.52 ℃; Phenolic urethane resin has good damping performance in the temperature range of 45.41 ~ 119.07 ℃ and 229.38 ~ 302.08 ℃.

(2) Most of the phenolic urethane resins react at 300 ~ 400 ℃, resulting in a significant decrease in strength.

(3) Phenolic urethane resin has been coked at 600 ℃, and the change of strength is very small; When the temperature is above 600 ℃, the strength of phenolic urea alkane resin increases slowly.