Abstract: With the help of AnyCasting software, the filling and solidification simulation analysis of permanent mold low-pressure casting process of aluminum alloy cover plate for GIS was carried out to understand the origination of casting defects in cover plate sealing groove, and optimized measures were provided. Finally, production validation was conducted. The results indicate that when the mold temperature is set at the lower limit and the upper limit for the working temperature, absence of shrinkage and porosity defects on the flange surface is observed according to the filling and solidification simulation analysis of the original process. The cover plate has a sealing groove defect, which is directly relevant with poor exhaust from the risers and the actual pouring inadequate height of the risers. The actual pouring height of the flange insulation riser is less than 1.24 times of the flange thickness, which has difficulty in effectively feeding the flange, resulting in shrinkage and porosity defects in cover plate sealing groove. Through optimizing designed scheme, the actual pouring height of the flange insulation riser is more than 1.55 times of flange thickness, and the qualified rate of the castings is over 99%. The simulation results are consistent with the actual ones.

1. Introduction

Aluminum alloy castings are widely used in industries due to their good surface gloss, corrosion resistance, low density, and high specific strength [1]. As a conventional component of Gas Insulated Switchgear (GIS), aluminum alloy cover plate castings are produced in large quantities annually with relatively simple shapes, typically utilizing the permanent mold low-pressure casting process. The cover plate material is ZL101A aluminum alloy, which is prone to defects such as shrinkage, porosity, and inclusions during production [2].

With the development of computer simulation technology, numerical simulation can optimize process design, ensure casting quality, shorten trial production cycles, reduce research and development costs, and improve production efficiency and product competitiveness [3]. By using numerical simulation technology, the probability of defects can be reduced by optimizing the casting process system and合理配置 cold iron and risers, thereby improving casting quality [4].

This study focuses on the casting shrinkage and porosity defects in the sealing groove of ZL101A cover plates produced by permanent mold low-pressure casting. Simulation analysis is used to assist in identifying the causes of these problems and optimizing the process to improve casting quality. The aim is to provide a reference for solving similar problems.

2. Material and Methods

2.1 Casting Material

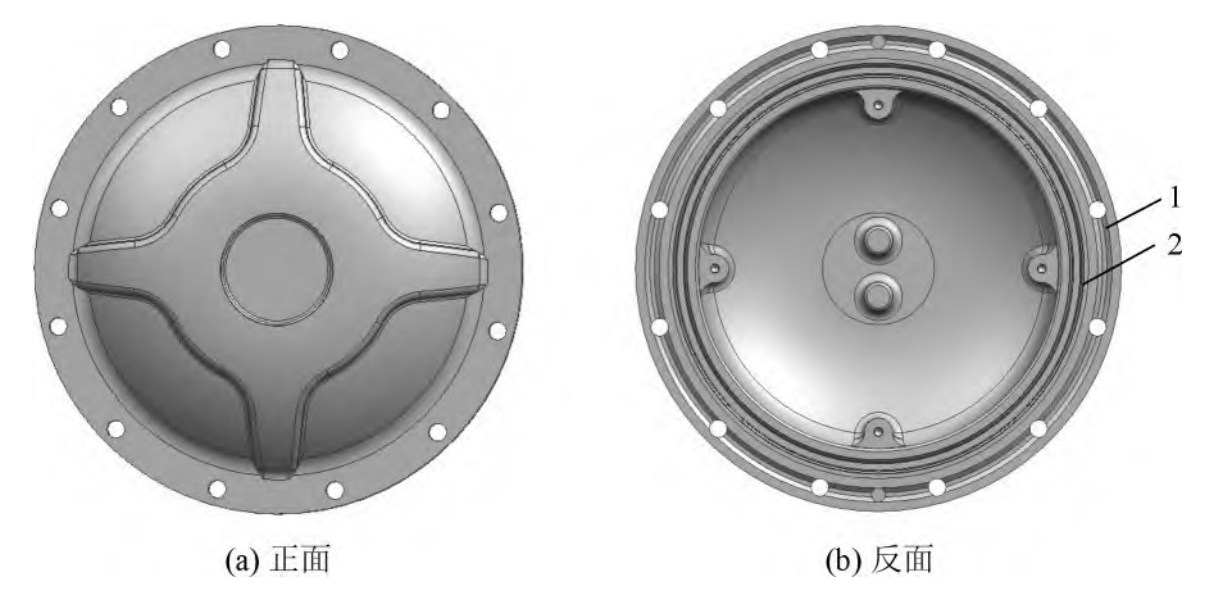

The GIS aluminum alloy casting cover plate studied is made of ZL101A alloy (composition shown in Table 1), requiring T6 heat treatment. The part weighs 13.2 kg, and a 3D diagram of the cover plate is shown in Figure 1. The cover plate has a basic “hat” shape with an outer ring as the flange, which has 12 through-holes. The wall has a “ring road”-shaped reinforcing rib structure. The front of the flange is the machined surface, with a sealing groove on the inner circle and a glue injection groove on the outer circle. The basic dimensions of the cover plate are ϕ520 mm × 83 mm, with a flange inner diameter of 386 mm, a flange thickness of 26 mm, a cover plate wall thickness of 15 mm, and a reinforced wall thickness of 20 mm.

Table 1. Chemical Composition of ZL101A Alloy (%)

| Element | Content Range |

|---|---|

| Ti | 0.08 ~ 0.20 |

| Mg | 0.25 ~ 0.45 |

| Si | 6.5 ~ 7.50 |

| Fe | ≤ 0.2 |

| Mn | ≤ 0.10 |

| Zn | ≤ 0.10 |

| Cu | ≤ 0.20 |

| Others | Single ≤ 0.05, Total ≤ 0.15 |

| Al | Balance |

2.2 Casting Process

The cover plate casting is produced using a permanent mold low-pressure casting process with an upper and lower mold structure. The basic process layout is shown in Figure 2. The “hat” is placed upside down, and the straight gate directly communicates with the top of the “hat” for casting filling. Four risers are set on the flange surface corresponding to the four bosses inside the “hat,” each equipped with a stone wool insulation sleeve. The stone wool insulation sleeve mainly serves to isolate the aluminum liquid from directly contacting the metal mold to prevent rapid chilling and solidification, allowing the aluminum liquid in the risers to solidify more slowly and feed the flange, thus ensuring the quality of the flange surface. The inner diameter of the insulation riser in contact with the flange surface is equivalent to the width of the flange surface, and the internal height is approximately 110 mm. The process yield rate is approximately 65%.

During the production of the cover plate using the original permanent mold low-pressure casting process, casting defects such as shrinkage porosity and shrinkage cavities appeared in the sealing groove of the flange surface at the root of the risers, as shown in Figure 3. Due to the strict airtightness requirements of GIS products for cover plate parts, such defects directly lead to the scrapping of the castings.

To investigate the causes of casting defects, simulation and analysis were first conducted to confirm the possibility of shrinkage porosity and shrinkage cavity defects on the flange surface during the filling and solidification process when the mold working temperature was set at the lower limit of 250°C and the upper limit of 350°C. Secondly, simulation and analysis were performed to determine the minimum height of the risers required for sufficient feeding of the flange. During the investigation of the causes of casting defects, it was found that the actual height of some risers, either individually or all, was lower than 40 mm. Based on experience, when the riser height is low, the hot spot at the flange surface near the riser is not fully introduced into the riser outside the flange surface, leading to shrinkage porosity and shrinkage cavities in the sealing groove at the root of the riser.

Subsequently, modeling was carried out for the original permanent mold low-pressure casting process of the cover plate and for different riser heights in the original process. The AnyCasting software was utilized to perform mesh generation, parameter setting, and simulation for the casting model. Prior to simulation, the entire model was meshed uniformly with a total of 10 million mesh elements. The thermophysical properties of ZL101A aluminum alloy material, such as the liquidus temperature of 614°C, solidus temperature of 556°C, solidification shrinkage volume change of 5.37%, and latent heat of 430.5 kJ/kg, were obtained from the AnyCasting software material database. The main simulation parameters are shown in Table 2. Among them, the heat transfer coefficient between the casting and the mold is 1000 W/(m2·K), the heat transfer coefficient between the casting and the insulation riser is 100 W/(m2·K), the heat transfer coefficient between the mold and the insulation riser is 100 W/(m2·K), and the heat transfer coefficient between the mold and the outside environment is 41.87 W/(m2·K).