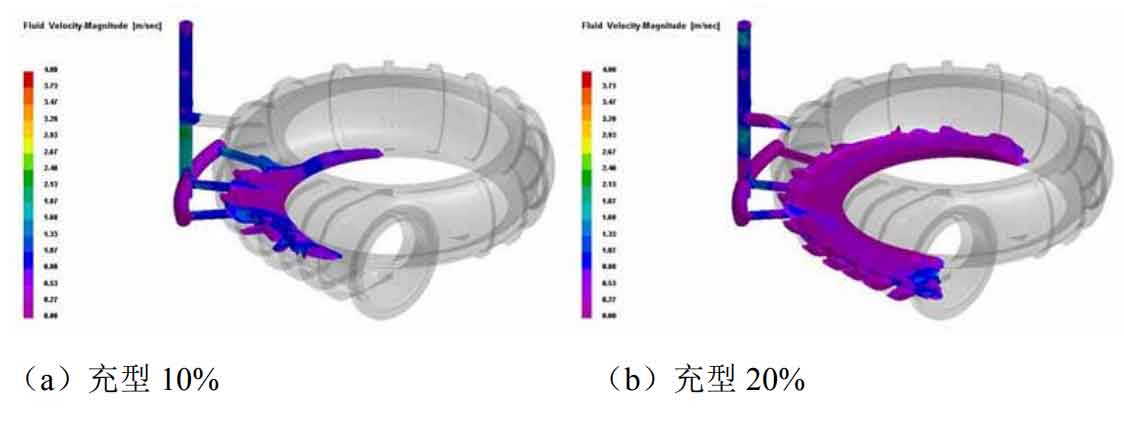

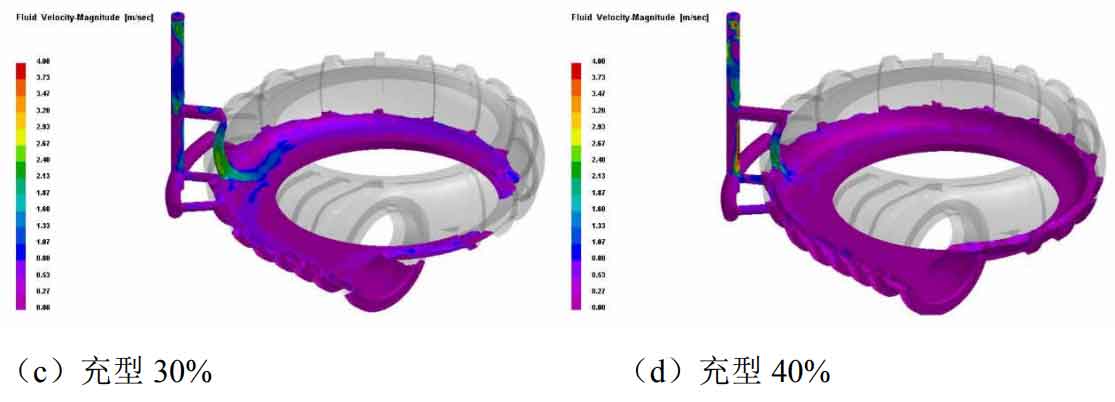

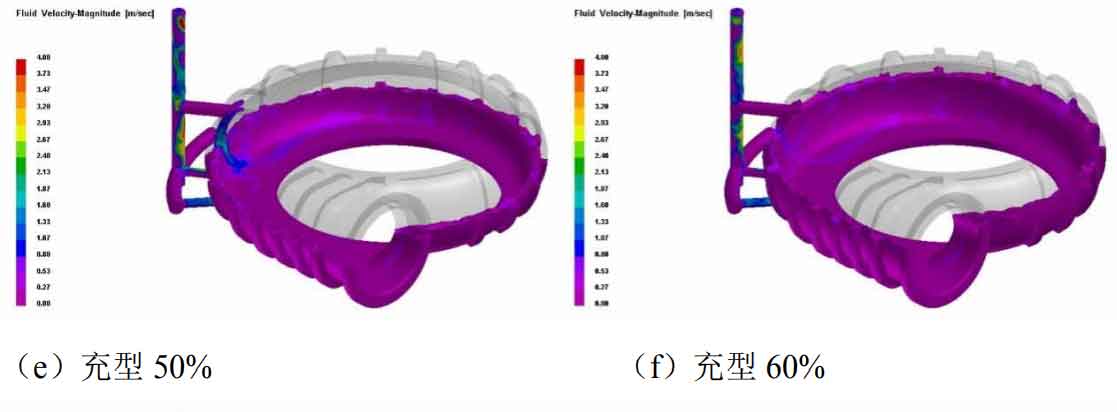

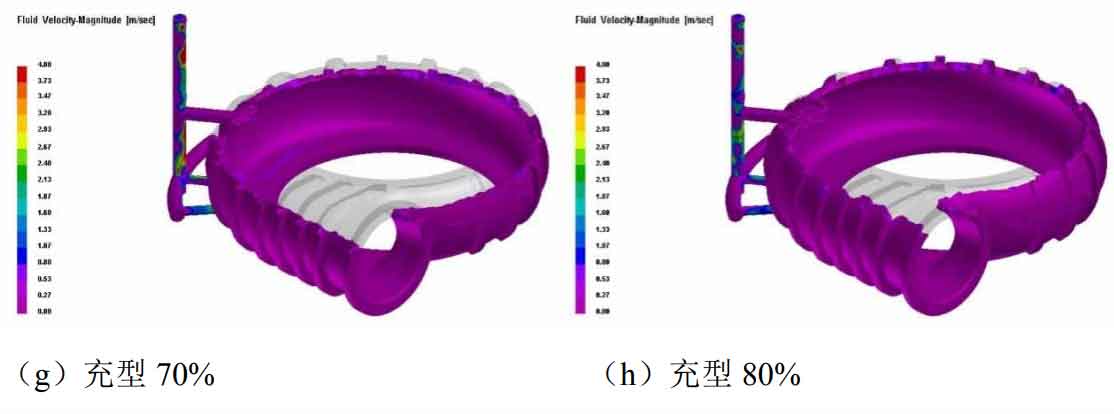

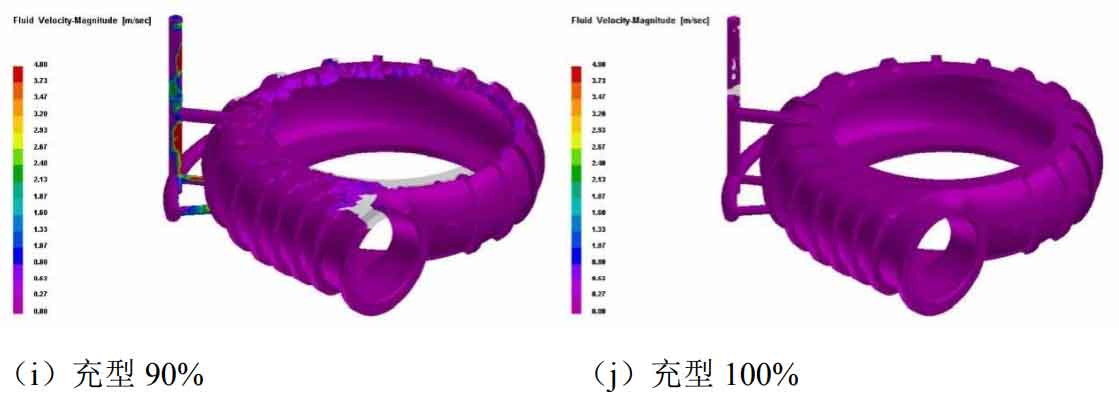

Figure 1 shows the simulation results of filling sequence and velocity field of each part of mud pump body in sand mold casting during mold filling when sand mold casting with gating system scheme is adopted. From the figure, the filling state of flowing metal in mold cavity can be clearly observed. When the filling is 10%, the flowing metal fills the bottom sprue and flows into the sand casting, while the upper sprue is not filled with metal; When the filling is completed by 20%, the flowing metal continues to flow into the sand mold casting from the bottom sprue, and the metal level rises steadily, but at this time, the flowing metal is about to fill the upper sprue; When 30% of the filling is completed, the flowing metal begins to flow into the sand mold casting from the upper inner sprue, but at this time, the metal liquid level is far from reaching the height of the upper inner sprue, and the upper inner sprue is filled in advance. As a result, the front flow speed of the flowing metal is very high, causing severe scouring and splashing on the mold wall, resulting in inclusions, sand holes, oxidation and other defects; When 40% of the filling is completed, the flowing metal continues to flow into the sand mold casting from the two-layer inner sprue at the same time. The front flow velocity of the flowing metal flowing into the sand mold casting from the upper inner sprue is still large, resulting in scouring of the mold wall, but at this time, the splashing phenomenon of the flowing metal is alleviated; Then, when 60% of the filling is completed, the metal level in the sand casting reaches the height of the upper inner sprue, and the flowing metal is filled stably until the filling is completed.

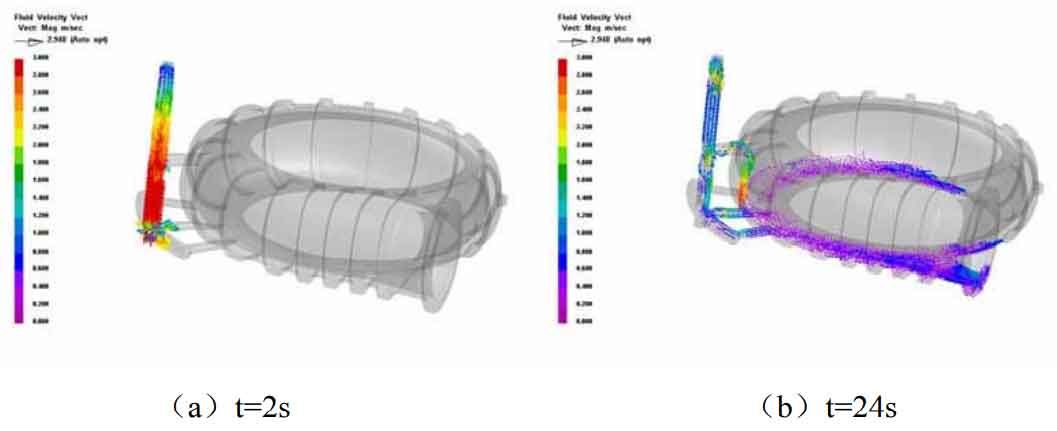

Fig. 2 is the velocity vector diagram of the mud pump body of flowing metal filled sand mold casting under the gating system scheme. It can be observed from the diagram that when t = 2S, the liquid metal fills the whole sprue, the flow front reaches the gate nest and begins to fill. At this time, the flow velocity is relatively large and the flow is disordered, resulting in serious scouring of the gate nest; When t = 24s, the molten metal has filled the upper sprue and began to enter the cavity. The flow front speed of the molten metal flowing into the cavity from the upper sprue is large and accelerated in the cavity, causing serious scouring to the bottom of the cavity.

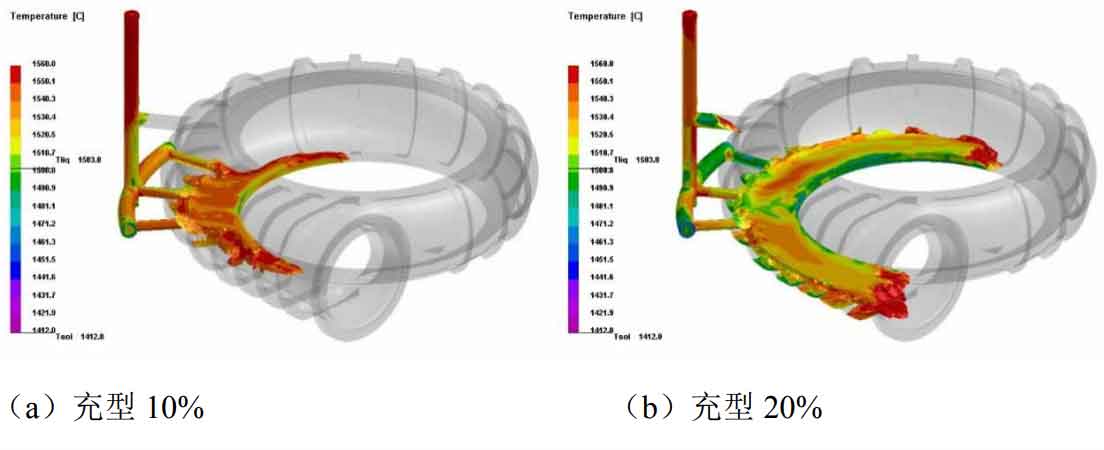

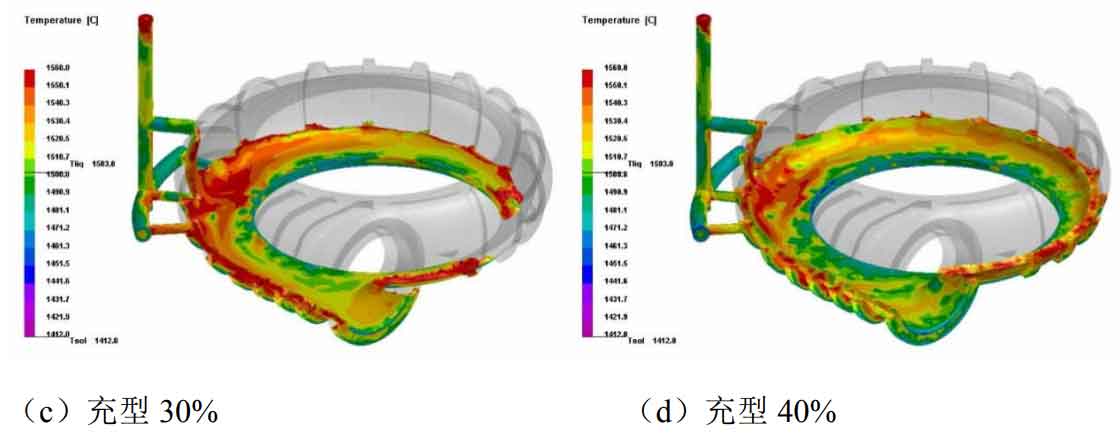

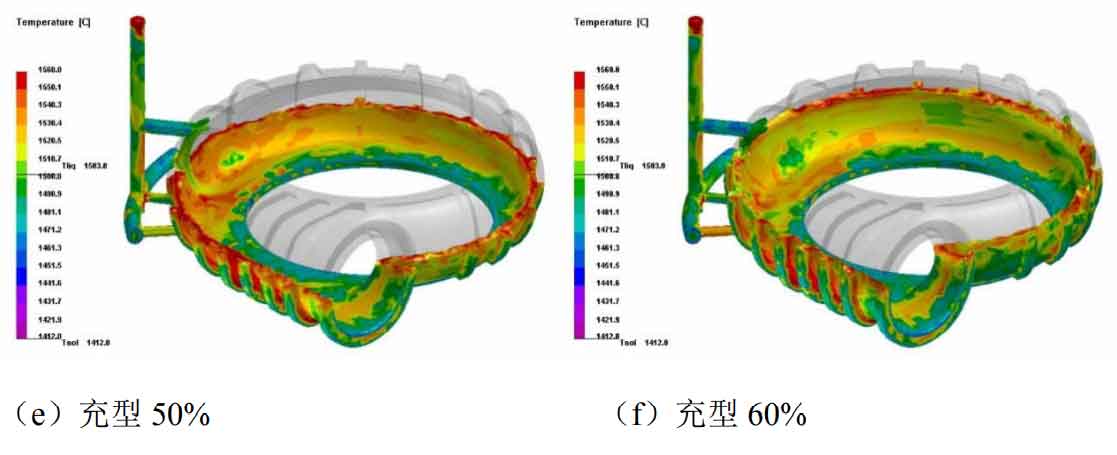

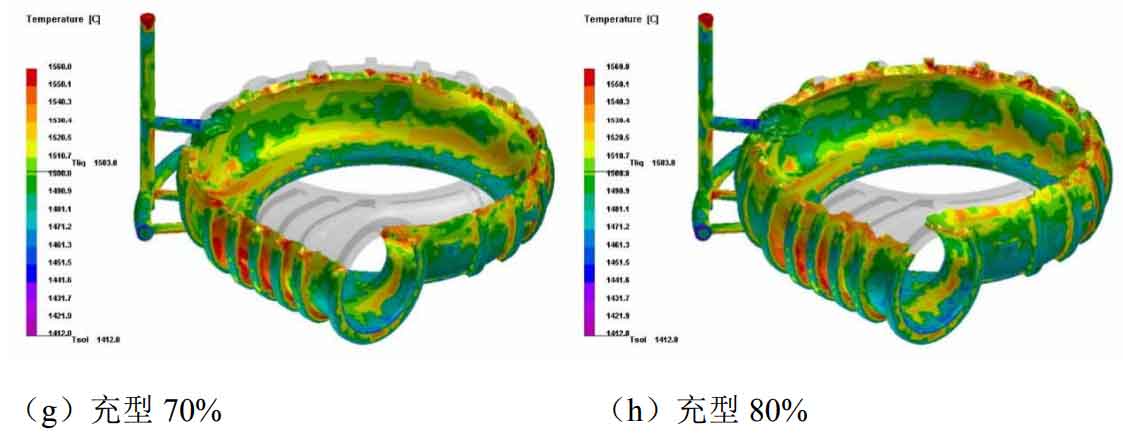

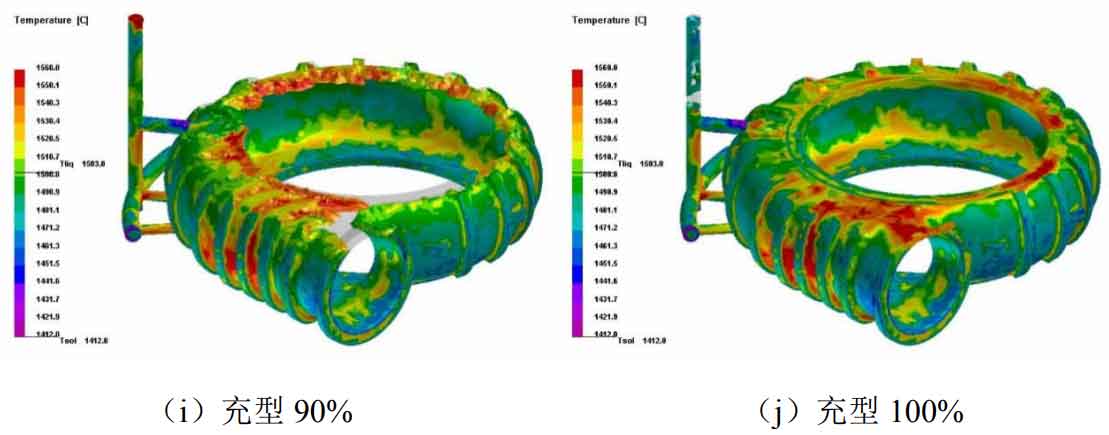

The simulation of sand mold casting filling process is the coupling calculation of velocity field and temperature field. Many sand mold casting defects such as cold shut, insufficient pouring, shrinkage porosity and shrinkage cavity are related to the distribution of temperature field in the filling process. Therefore, when analyzing the filling effect of gating system, we should not only observe the distribution of velocity field, but also analyze the change of temperature field, The temperature distribution of molten steel in the filling process of sand casting mud pump body is shown in Figure 3. From the simulation results, it can be clearly observed that the temperature of the metal liquid at the bottom of the sand casting mud pump is lower than that of the upper metal liquid when the pump body of the sand casting mud pump is filled with 40%. At this time, the bottom-up temperature gradient distribution has been well formed, which provides a better initial temperature condition for the subsequent solidification process, so that the sand casting can form orderly solidification, Reduce the possibility of shrinkage porosity, shrinkage cavity and other defects in the mud pump body of sand mold casting; The pouring temperature of sand casting mud pump body is 1560 ℃. It can be seen from (I) that when the filling process is basically completed, the temperature of sand casting mud pump body is maintained at about 1510 ℃. During the whole pouring process of sand casting mud pump body, the temperature of molten metal decreases slightly, which further reduces shrinkage At the same time, it can effectively avoid the oxidation of liquid steel in the pouring process of mud pump body of sand casting.