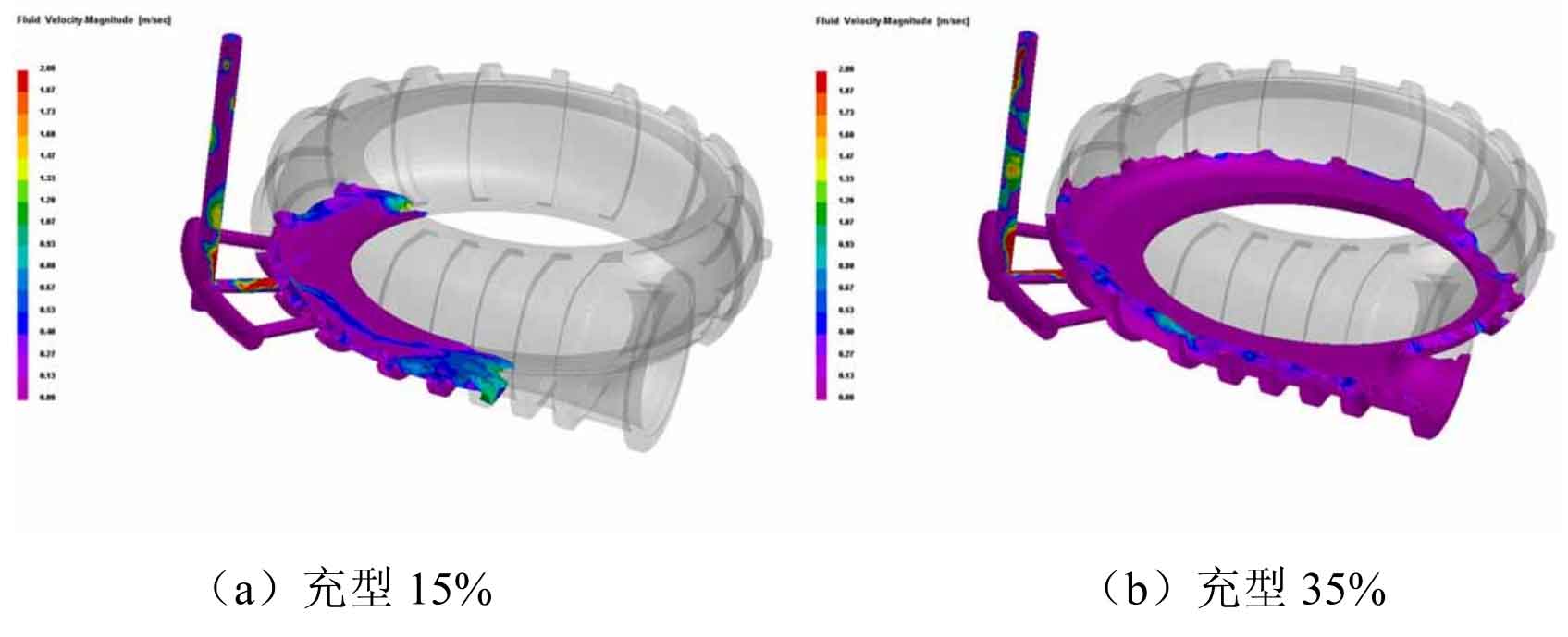

The simulation results of the filling process when the pump body of sand casting mud pump is poured by the gating system are shown in Figure 1. It can be seen from the figure that the liquid metal enters the bottom of the mold cavity after filling the inner sprue. The speed of the liquid metal at the flow front is small, and the filling process is slow. After the liquid metal fills the bottom of the mold cavity, the liquid level gradually rises until the whole mold cavity is filled. The filling process is relatively stable, without air entrainment, air wrapping and other phenomena, and the scouring of liquid metal on the mold wall is small during the filling process.

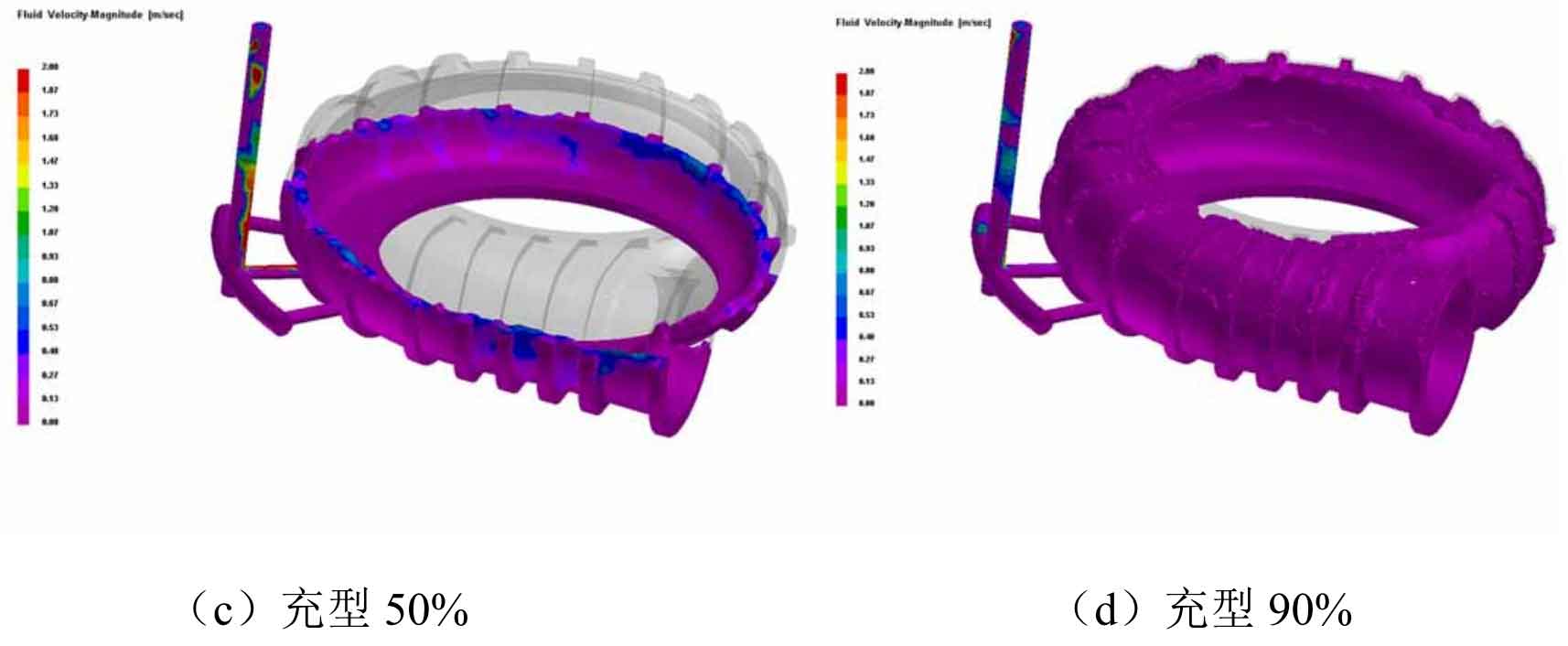

The simulation results of the temperature field during the filling of the mud pump body in sand mold casting are shown in Fig. 2. According to the analysis of the temperature field, the temperature when the molten metal fills the inner sprue and starts to fill the mold cavity is about 1500 ℃, and the temperature at the flow front is maintained at about 1550 ℃; When the molten metal just fills the bottom of the cavity, the temperature of the molten metal has dropped below 1500 ℃, the temperature of the local area is only 1420 ℃, and the temperature of the flow front has dropped to 1530 ℃; When the pouring of the sand casting mud pump body is basically completed, the temperature of the main body of the sand casting mud pump body has dropped to 1480 ℃, while the temperature of the area at the bottom of the sand casting mud pump body away from the inner sprue has dropped below the solidus line and began to solidify.

When pouring the mud pump body of sand casting, the mold filling time is too long, the sand mold is affected by the radiant heat of liquid metal for a long time, and the mold wall surface is easy to crack or fall off to form sand inclusion defects; The metal liquid rising in the mold cavity has a long contact time with the air in the mold cavity, and because ZG35 is easy to be oxidized, the surface of sand casting mud pump body is easy to be oxidized during filling to produce oxide scale; During the pouring process of mud pump body in sand casting, the temperature of liquid metal decreases greatly, which will aggravate the oxidation of liquid metal, but the metal and oxide solidified prematurely on the casting surface form a thin film layer; At the end of filling, the temperature of molten metal drops too much and does not form a good temperature gradient distribution, which will lead to shrinkage and other defects in the pump body of sand casting mud pump during solidification and affect the quality of castings.