Numerical simulations were conducted on 6082 aluminum alloy automotive flange parts using different extrusion casting process parameters, and the location of shrinkage porosity defects was predicted. The results show that the filling of the automotive flange parts under various parameters is complete, and during the pressure holding process, due to the large wall thickness at the corresponding parts of the three protrusions, they finally solidify; After the pressure holding is completed, the temperature of the pressure bearing part of the mold is significantly higher than other parts, and the temperature distribution shows unevenness. In the actual die-casting process, attention should be paid to protection to avoid mold damage. The shrinkage and loosening positions mainly occur at the thick wall positions corresponding to the three convex platforms, which is consistent with the temperature field results. The forming test obtained excellent castings, indicating that the numerical simulation results are accurate and reliable.

With the rapid development of our country’s economy, cars have become an essential means of transportation in people’s lives. along with It has also brought serious environmental pollution, energy shortage and other problems, and energy conservation and emission reduction are urgent. Lightweight automobiles are an effective way to save energy and reduce emissions, which can be achieved through optimizing the body structure and selecting lightweight alloys. Among them, selecting lightweight alloys is the most direct and effective. In recent years, high-quality materials such as fiber-reinforced composites, engineering plastics, aluminum, magnesium, titanium alloys, etc. have been widely used. Aluminum alloys have attracted widespread attention due to their low density, high strength, strong corrosion resistance, excellent processing performance, easy recycling, high specific strength and stiffness, and heat treatment strengthening. As a green, short process, safe and reliable green near net forming technology, squeeze casting combines the advantages of casting and forging, and is highly favored in industrial production. Compared to liquid and plastic forming, squeeze casting has the advantages of strong process adaptability, simple process, heat treatable production parts, and dense microstructure. Squeeze casting can be divided into direct squeeze casting, indirect squeeze casting, composite liquid forging, and intelligent liquid forging. The materials that can be formed by squeeze casting technology are called squeeze casting materials. The materials used in squeeze casting are mainly cast aluminum alloys, which are also used in forging metal materials such as aluminum alloys, magnesium alloys, copper alloys, zinc alloys, etc. Among them, aluminum alloys are the most widely used.

Setting reasonable process parameters is a key factor in improving the performance of extruded casting parts. Squeeze casting process parameters The number includes pouring temperature, mold preheating temperature, extrusion pressure, holding time, pouring speed, etc. By using numerical simulation technology, it is possible to predict the form of defects in advance, in order to improve the forming process plan, reduce production costs, and shorten the manufacturing cycle.

Temperature Field Analysis of Pressure Holding Solidification Process of Castings

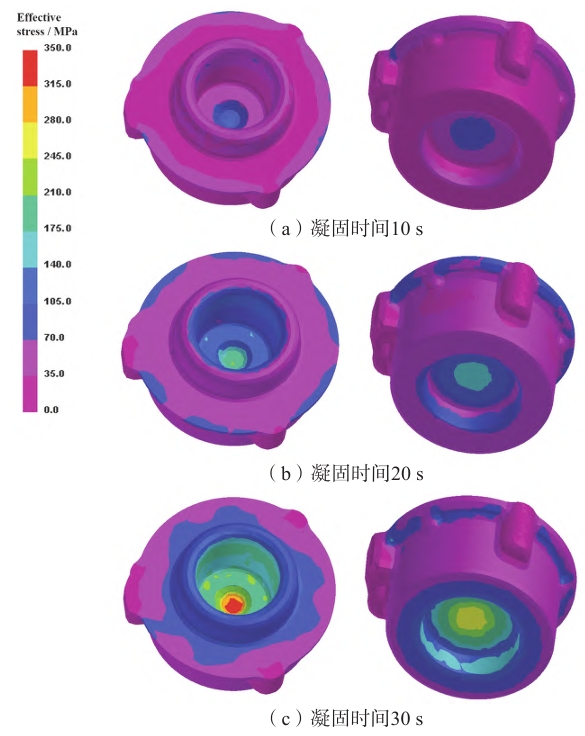

At the beginning stage of solidification and insulation of castings, the temperature on the outer surface of the casting is relatively uniform and varies between 606~633 ℃. The temperature on the outer side of the upper end face of the casting is lower than the temperature at the corner of the inner and outer cylindrical surfaces of the upper flange. This is mainly because the outer side of the upper end face of the casting is the joint between the upper and lower molds, and the gap between the upper and lower molds leads to faster heat conduction during the insulation process. The temperature mainly shows a trend of gradually decreasing from the inside to the surface, because the casting cylinder wall is in direct contact with the mold. According to the preset parameters, the mold temperature is much lower than the pouring temperature of the molten metal, so the temperature of the part in contact with the mold decreases much faster than the inside of the casting. For the side wall of the casting, the increase of three protrusions leads to an increase in wall thickness, which requires longer heat dissipation during the solidification process, and therefore may result in thermal joints in the internal position. Distribution diagram of residual liquid phase during the pressure holding solidification process of castings with solidification fractions of 30%, 60%, and 90%. During the solidification process of molten metal, the inconsistent rate of temperature decrease at different locations may lead to the formation of a solid skeleton inside the molten metal, which will seriously hinder the flow process of the molten metal and weaken the forced shrinkage ability of the casting under extrusion pressure. In the initial stage of the pressure holding process, the upper end of the flange, the upper end face, the side walls, the bottom, and other positions in direct contact with the mold solidify first, and the liquid phase is mainly concentrated and continuously distributed inside the casting. As the pressure is maintained, the metal liquid decreases and continues to concentrate around the center of the upper flange. At this point, the contraction channel has not yet been disconnected, and the pressure transmission is good. As the holding pressure continues, when the solidification state reaches 90%, the remaining liquid phase breaks off and is distributed in the raised position on the side wall and the cylindrical part of the lower body of the casting. The shrinkage channel is closed, becoming an isolated liquid phase zone, which is prone to shrinkage and porosity defects.

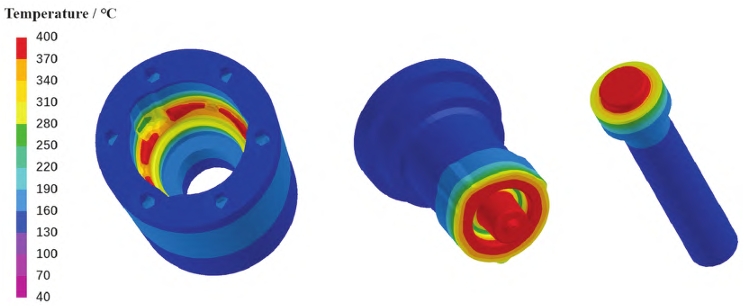

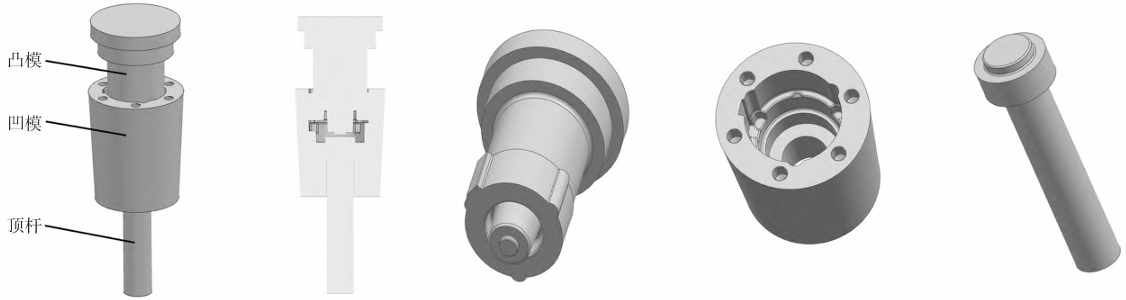

The temperature distribution of the mold after the pressure holding of the casting is completed, and the temperature distribution pattern is basically the same. Taking the results of numerical simulation No. 5 as an example for explanation. After the pressure holding is completed, the temperature field of the mold shows an uneven distribution, with the temperature at the direct contact area with the molten metal being higher than that at the distant contact area, and the temperature change on the outside of the mold is not significant. The temperature field of the concave mold shows a decreasing trend from the center of the casting to both sides in the height direction. The temperature field changes in the parts in contact with the casting are complex, and the temperature of the locally protruding corners exceeds 370 ℃, which is caused by the large temperature difference between the mold and the molten metal. For convex molds and top rods, the temperature of the main pressure bearing parts is higher than that of other parts. In the process of squeeze casting, pressure can improve the efficiency of heat transfer, so during the holding stage, the axial pressure is greater than the pressure in other directions, so the axial center pressure of the punch and top rod is greater than that in other directions. During the protection process of the mold, special attention should be paid to this area to avoid reducing the forming quality due to mold damage.

Squeezing casting test verification

The numerical simulation results can provide guidance for forming experiments, but the reliability of the results still needs to be further verified through forming experiments. Based on the numerical simulation results, select the optimal process plan: pouring temperature of 700 ℃, mold Conduct extrusion casting test verification with a temperature of 220 ℃, holding time of 30 s, and a specific pressure of 147 MPa (maximum value of hydraulic press). It can be seen that the surface quality of the flange parts obtained by extrusion casting is high, without common defects such as insufficient pouring, shrinkage porosity, shrinkage porosity, and macroscopic cracks. Under this parameter, the metal liquid filling is stable and well replenished, which is in good agreement with the numerical simulation results. This also indicates that squeeze casting, as a high-quality forming technology, has significant advantages in welding holes and reducing defects such as shrinkage and porosity.

conclusion

(1) During the pressure holding process, the temperature field shows a gradually decreasing trend from the upper flange core to other parts. The main cylinder at the lower end of the flange with a larger wall thickness finally solidifies. After the pressure maintenance is completed, The temperature of different parts of the mold is inconsistent, manifested by the protruding structure of the concave mold cavity and the significantly higher temperature of the central pressure bearing part of the punch and top rod than other positions. During the forming process, attention should be paid to the protection of the mold.

(2) The defect location predicted by the software is highly consistent with the analysis of the temperature field during the solidification process, that is, the shrinkage and porosity positions are mainly concentrated at the corresponding positions of the three convex platforms on the side, and should be paid attention to during forming.

(3) The results of the forming test indicate that the numerical simulation parameter design is reasonable and the results are accurate and reliable. In actual production, the pouring temperature can be set to 700 ℃, the mold temperature can be set to 220 ℃, and the holding time can be set For 30 seconds, the specific pressure can be set to the maximum specific pressure that the hydraulic press and mold can withstand.