During smelting, weigh each raw material according to the weight percentage required by the composition, melt it in the electric arc furnace, tap at about 1620 ° C, add alloy to the smelting furnace for alloying before tapping, desulfurization, deoxidation, detection and adjust the chemical element composition content to qualified; The temperature in the ladle is about 1564 ° C, the ladle is sedated for 7 minutes, the temperature is about 14 ° C, and the pouring temperature is about 1550 ° C.

During pouring, according to the casting process described above, the flow of liquid flow in the pouring system during mold filling shall be as stable as possible to avoid disturbance. A filter is set in the gating system to absorb the inclusions of the steel grade and make the liquid steel fill the mold in the state of laminar flow; Around the injection, go to the cavity to flush argon for about 10 minutes to reduce the oxidation in the cavity. When the teapot ladle is used to replace the simple tilting ladle, the inclusion in the liquid flow must be avoided as far as possible. The grain refinement of bainite steel lining plate will be beneficial to the use of metal mold sand coating and reducing pouring temperature.

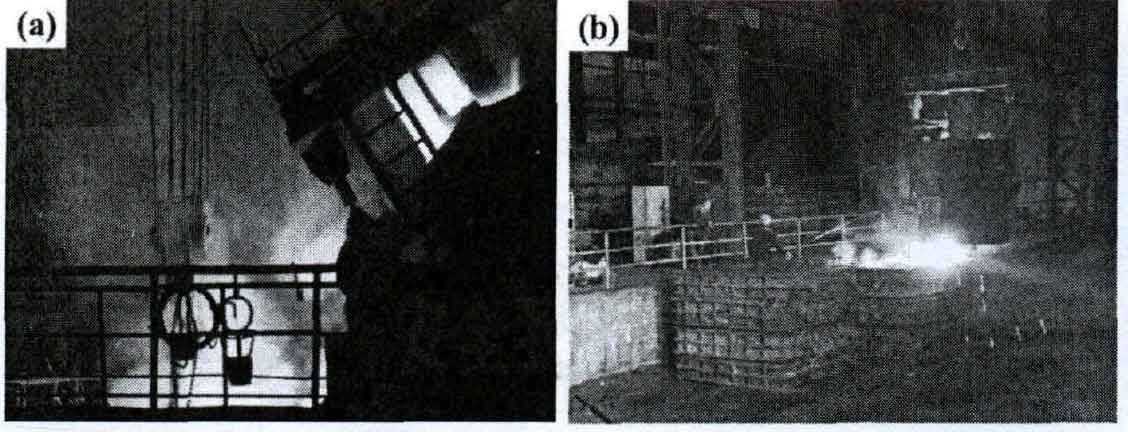

According to the preparation process, a set of shell horse composite wear-resistant cast steel conical crusher lining plate is smelted and cast, as shown in the figure. When casting the lining plate, two test bars are cast at the same time. Test bar 1 is used to obtain the chemical composition of the lining plate and conduct the final heat treatment calibration in the laboratory. Test bar 2 will be heat treated together with the large lining plate, and test bar 2 is used to obtain the mechanical properties of the lining plate material after heat treatment.

The chemical composition results of the bainite Martian multiphase wear-resistant cast steel liner after smelting and casting are obtained from test bar 1. It can be seen that the content of element C in the chemical composition is 0.04% lower than the required lower limit, and the other elements meet the above composition requirements. The deviation here may reduce the strength and hardness of the lining plate, but generally speaking, its composition is basically qualified.