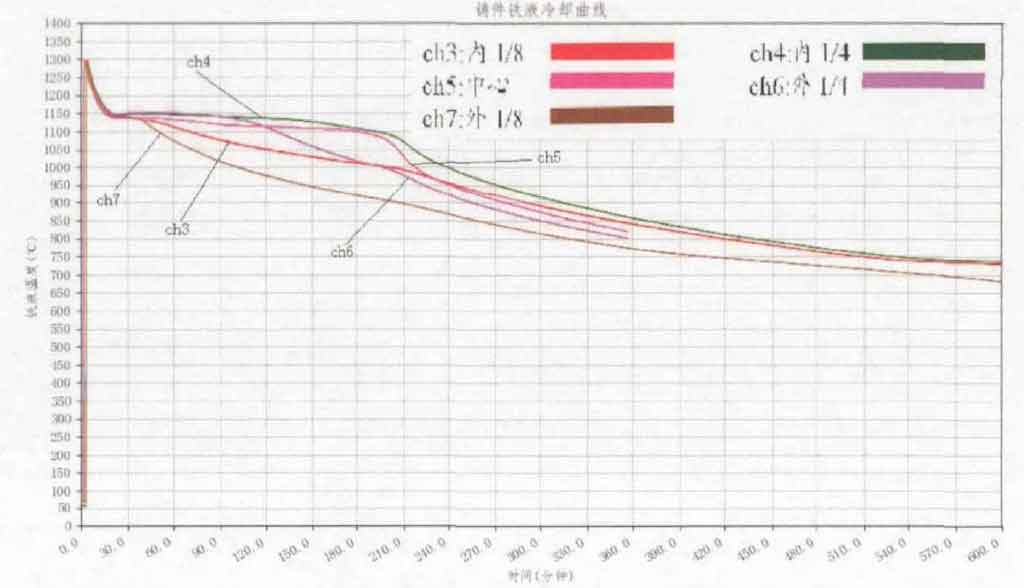

The temperature measurement curves of different positions of 45 ° sector test block are shown in Fig. 1. The cooling conditions and cooling rates at different positions of 45 ° sector test block are different, resulting in different solidification time.

Based on the differential analysis of the cooling curve of the temperature measuring point of the test block, the solidification temperature, solidification time and other parameters of each position of the test block are obtained

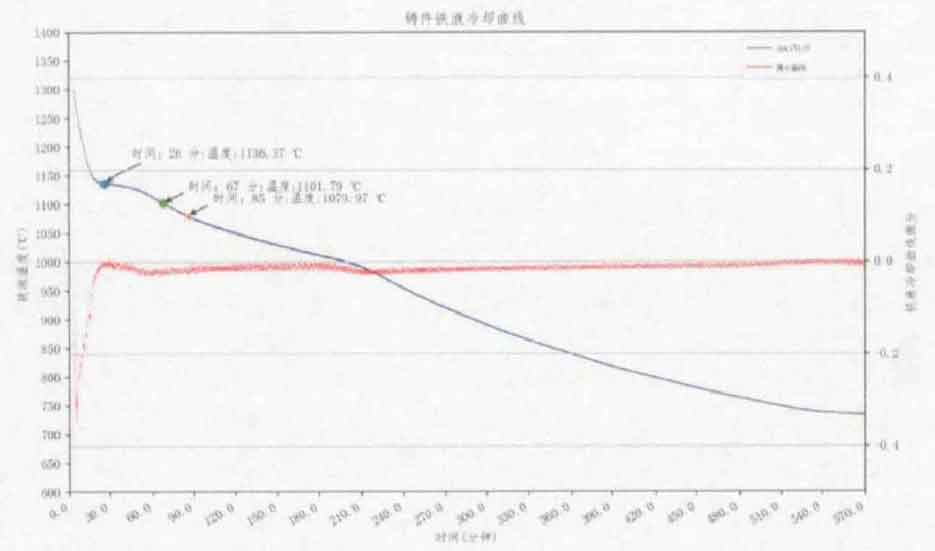

The inner 1 / 8 is close to the chill, and the cooling condition is good. When the molten iron enters the mold cavity, a large amount of supercooling occurs there. The results show that the solidification temperature at the inner 1 / 8 of the steel decreases from the theoretical 1u7 ° C to 1136 ° C. after entering the solidification stage, the release of the latent heat of solidification and the heat conduction of the cold iron reach a balance. With the release of the latent heat of solidification and the rapid rise of the cold iron temperature, the heat dissipation capacity of the cold iron decreases. When the temperature drops to 1080 ° C at 85min, the solidification is completed. The solidification characteristic curve of inner 1 / 8 is shown in Fig. 2.

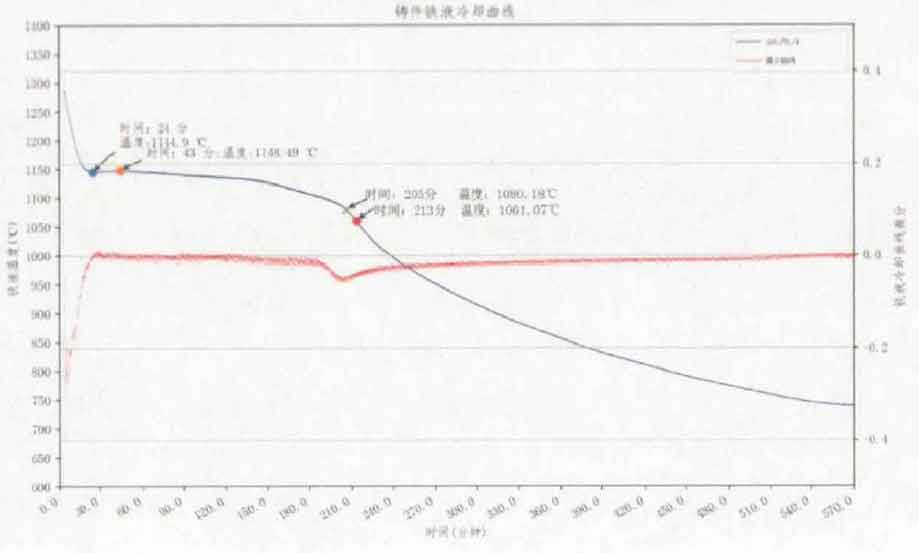

The temperature of the inner quarter drops to 1144.9 ° C in 24min, and then enters the solidification stage. The inner quarter is far away from the chill, and the cooling condition is much worse than that of the inner quarter. As the solidification proceeds, the latent heat of crystallization and the heat dissipation of the mold reach a balance, and the inner quarter solidifies at a constant cooling rate, maintaining the coexistence of solid and liquid for a long time. There is no solidification platform at this place, but it solidifies in a fixed temperature range, and the temperature drops to 1080 ° C in 205min to complete solidification. The solidification characteristics of the inner quarter are shown in Fig. 3.

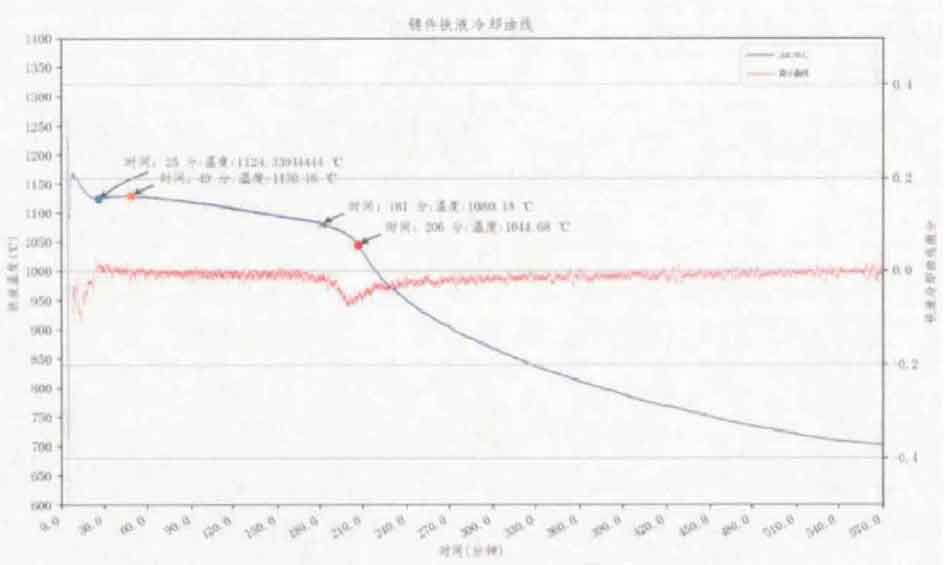

When the center position is 25 min, the temperature of molten iron will drop to 1124 ° C and enter the solidification stage. The solidification curve at the center is similar to that at the inner quarter, and the latent heat can not be effectively transferred. Due to the poor heat dissipation condition at the center, the solid-liquid two-phase coexistence state is maintained for a long time until the temperature drops to 1080 ° C, and the total solidification time is 181min. The solidification characteristic curve at the center is shown in Figure 4.

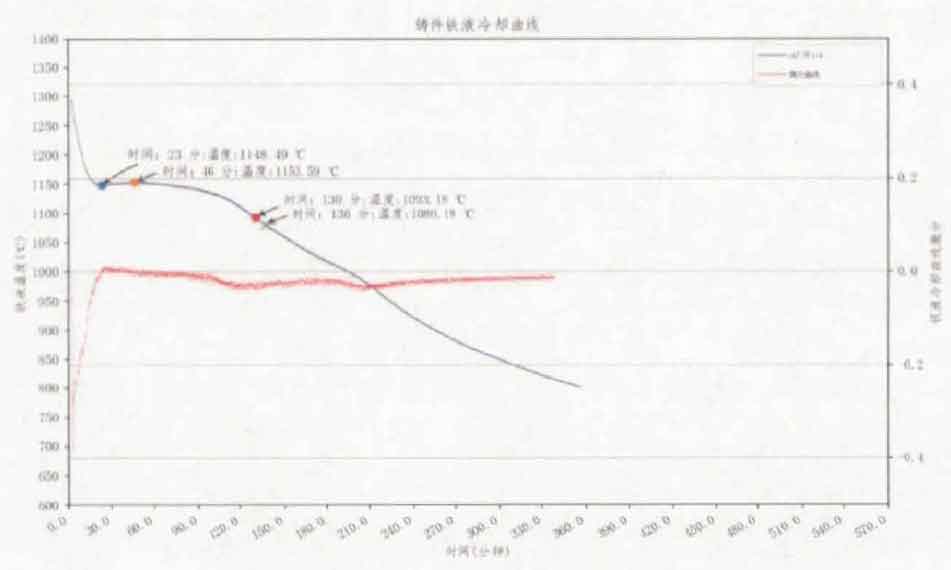

As the temperature measuring point deviates from the center, the heat dissipation capacity increases and the cooling speed increases. The temperature of molten iron drops to 1148.5 ° C at 1 / 4 of 23min, and then it enters the solidification stage. Due to the improvement of cooling conditions, the solidification speed is accelerated and the temperature drops to 1080 ° C in 136min. Compared with the solidification process at the inner quarter, Xibu quarter enters the solidification stage earlier, and the solidification time is shortened by 54%. The solidification characteristics of the outer quarter are shown in Fig. 5.

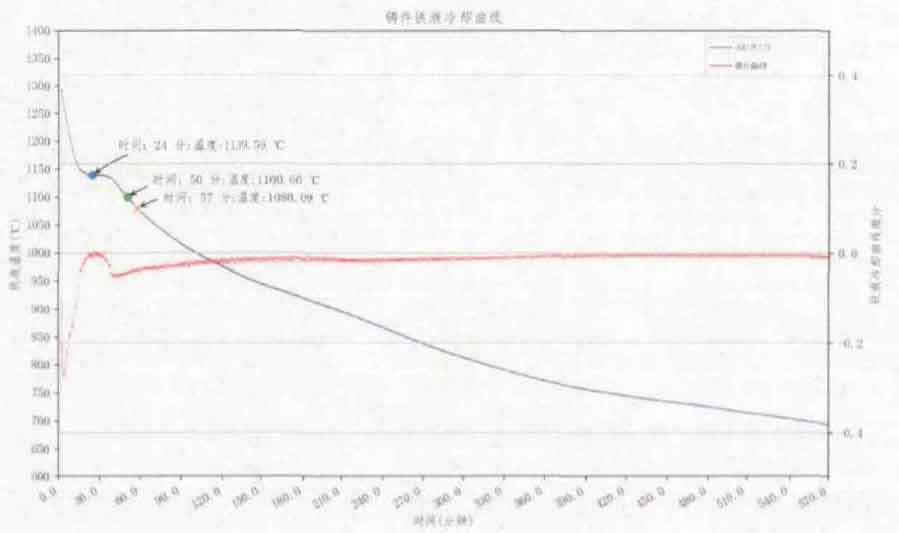

The outer 1 / 8 is close to the metal mold. The good chilling effect and excellent thermal conductivity of the metal mold make the solidification begin at the first place. At 23 min, the temperature of the molten iron decreases to 1139.6 ° C and enters the eutectic stage. Because of the good cooling conditions at Xibu 1 / 8, the latent heat of solidification is released effectively, and the temperature of the outer 1 / 8 in the solidification stage decreases continuously until the end of solidification. When the temperature drops to 1080 ° C, the solidification is completed, and the solidification time of the outer 1 / 8 is shortened to 57 min. Compared with the inner 1 / 8, the solidification is advanced by about 1 / 3 and the solidification time is shortened by about 1 / 3. The outer 1 / 8 temperature measurement curve is shown in Fig. 6.

To sum up, it is concluded that:

(1) With the temperature measuring position close to the inner quarter, the worse the cooling condition, the longer the solidification time;

(2) At the same distance from the center, the cooling condition on the outside of the test block is better than that on the inside;

(3) The solidification time of the inner quarter is the longest, and the final solidification position is not the center of the block, but near the inner quarter;

(4) There is no solidification platform in the solidification process of 45 ° fan-shaped block, and the solidification of each position of the block is carried out in the range of 1147 ° C ~ 1180 ° C;

(5) The order of solidification is: outer 1 / 8, inner 1 / 8, inner 1 / 4, center 1 / 4, inner 1 / 4. The order of solidification time is: 57min, 1.42h (85min), 2.27h (136min), 3.02h (181min), 3.42h (205min).