1. Increase the gate section size in the gating system

Gate size in main core: changed from 33.5 / 34.6 * 8 to 33.5 / 33.4 * 10, 12 in total; The inner gate of the lower half mold of the appearance is changed from 50.2 / 47.7 * 7.5 to 50.2 / 46.9 * 9.5, a total of 6; On the original resin sand molding mold, increase the cross-sectional area of the inner gate of the main core and the lower half of the inner gate of the outer mold, and change the original closed type to semi closed and semi open type to ensure rapid filling of the mold. The purpose is to reduce a large amount of gas after the sand core is baked by molten iron before the molten iron is poured into the mold cavity. Casting 6T cylinder block by iron mold process is to quickly fill the whole mold cavity with molten iron and gradually solidify rapidly. So as to ensure that the molten iron has solidified before the sand core is heated and gassed, prevent the heated sand core gas from penetrating into the non solidified molten iron, and reduce the casting porosity of the sand core from invading into the casting.

2. Move the exhaust needle, improve and increase the exhaust of casting porosity needle

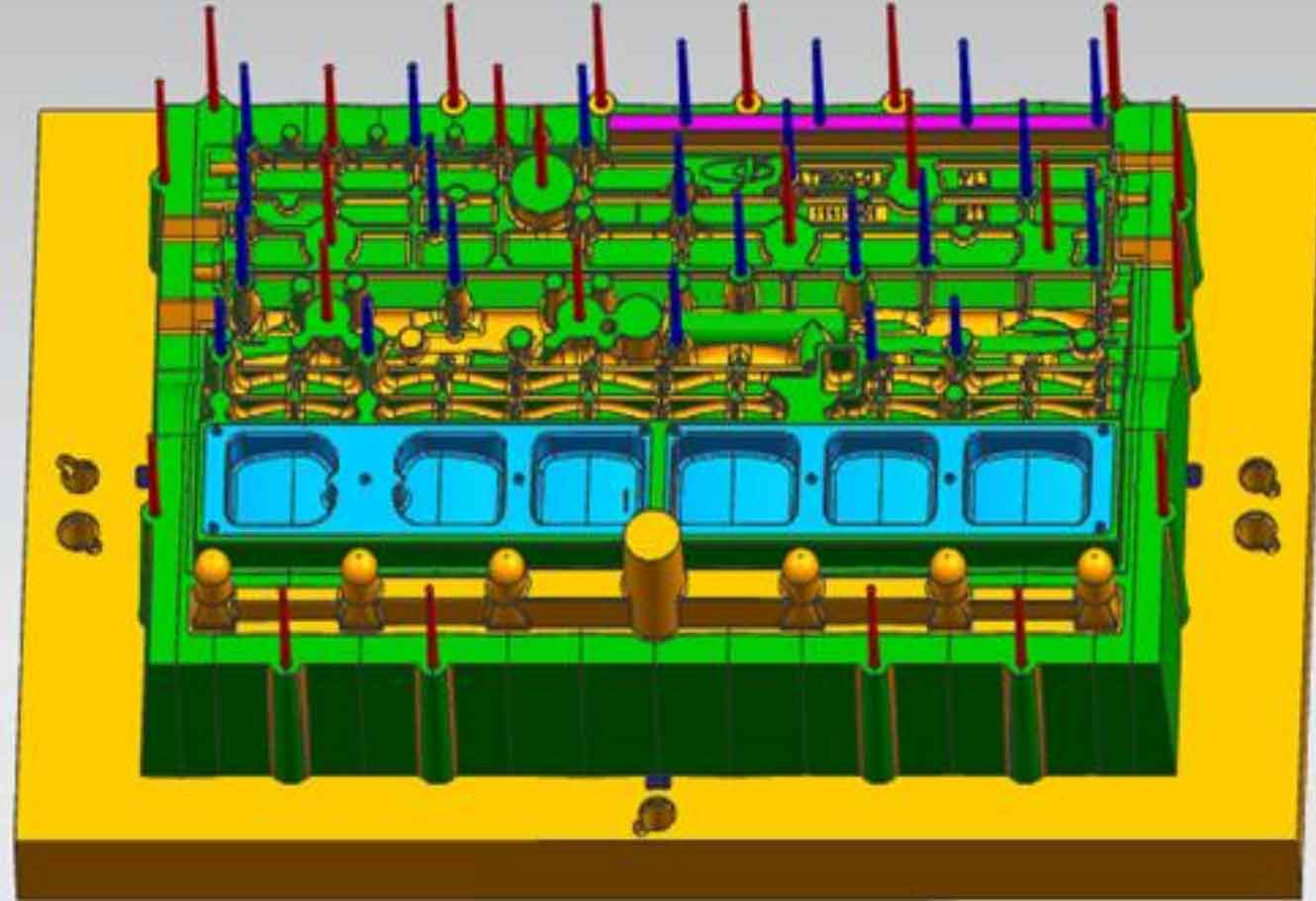

Move the casting porosity needle at the core head of the water jacket sand core that was biased or not, so as to ensure the smooth exhaust of the core head during the pouring of molten iron. The casting porosity needle is evenly distributed on the boss (the highest part) on the upper part of the water jacket surface. If there is no exhaust, the casting porosity needle shall be added, as shown in Figure 1. Stomatal needle is generally Φ 15mm, which is conducive to the discharge of gas in the mold cavity. The new improved iron mold also makes perforation and casting porosity needle displacement and increase improvement at the corresponding position.

Requirements for the height of casting porosity needle: all casting porosity needles at the new core head shall pass through the outside of the box surface. The cavity casting porosity needle communicated with the casting is made into an air needle with a height of 5-7mm from the box surface, which does not pass through the box surface, so as to ensure that the gas in the mold cavity can be discharged during molten iron pouring, and also ensure that the molten iron does not fly out of the iron box surface during pouring.

Casting porosity needles shall be properly arranged around the main core to ensure smooth exhaust of the core around the whole sand core. Casting porosity needle arrangement: generally, 4-5 casting porosity can be arranged on the long side and 2-3 casting porosity can be arranged on the short side. Normally, the casting porosity needle of the peripheral core head is required to pass through the box surface, which is conducive to the smooth exhaust of the core head such as the main core and insert core.

3. Shorten pouring time

Before the improvement of the gating system for 6T cylinder block, under the condition of ensuring the hot metal temperature (1420 ℃), the pouring time is more than 48S, and about 80% of the upper surface of the casting has casting porosity. After increasing the inner gate, the pouring time is controlled below 42s under the condition that the hot metal temperature process remains unchanged, the gate cup is filled, and there are no casting porosity on the upper surface of the casting.

4. Properly add measures (or process) to exhaust on the mold to reduce the problem of casting porosity

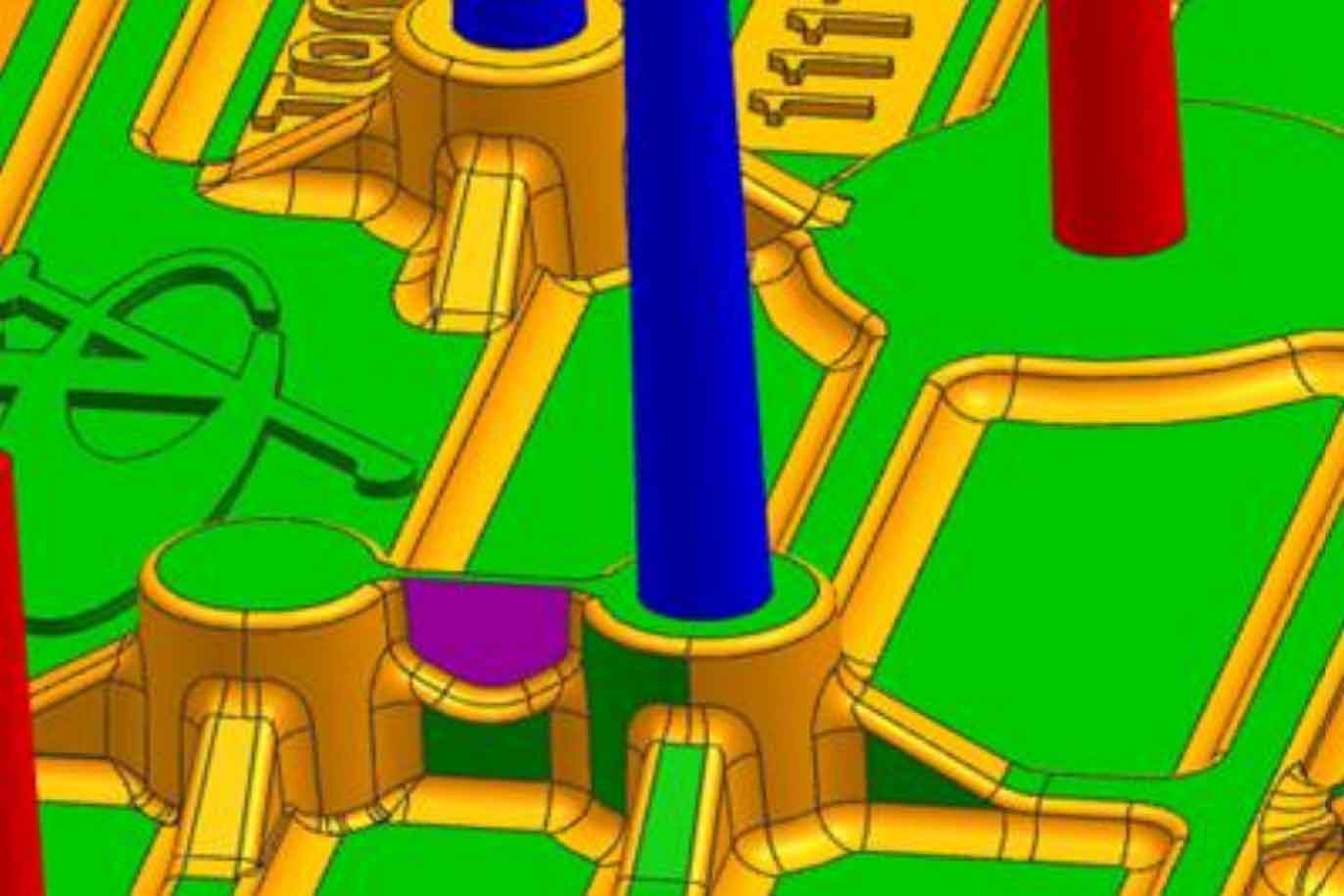

Because the upper surface structure of 6T cylinder block is special, there are two bosses with the same height in one part, and there are often casting porosity in one boss. The reason is that the boss is suffocating and cannot be discharged. To solve this problem, we add a process exhaust slot, as shown in Figure 2 (purple part). Add a process exhaust plate (1.5mm), connect the two bosses, and lead the gas from the common boss to the exhaust needle boss, so as to discharge out of the box. After the process of adding exhaust sheet through the die, the problem of boss casting porosity is solved. New process exhaust fins can be cleaned, polished and trimmed with tools during casting cleaning.

5. Local structure optimization

In the original design, there is no stiffener in the water jacket core. Due to the consideration of casting porosity, the hot metal of the water jacket turns over from the bottom and connects with the hot metal on the other side. The process is long and easy to turbulence, resulting in many casting porosity, suffocation, etc; If it cannot be discharged smoothly, casting porosity or cold shuts will be generated on the upper surface of the casting water jacket sand core.

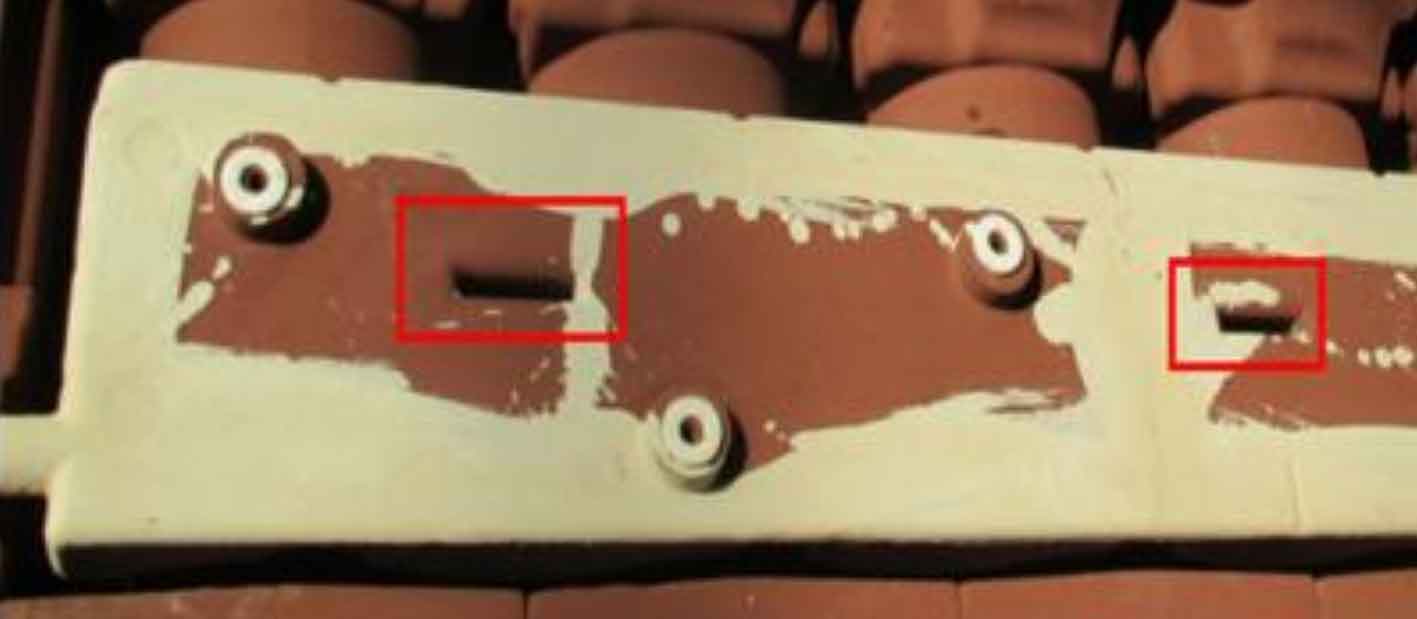

According to the principle of casting porosity formation, we take measures as follows: add ribs in the middle of the water jacket core, as shown in Figure 3. After pouring, some molten iron can emerge from the middle of three water jacket cores to disperse molten iron and reduce the turbulence of molten iron; At the same time, after pouring the molten iron, part of the molten iron in the middle of the water jacket goes up to shorten the filling and flow distance of some molten iron and disperse the gas in the mold cavity; After adding the ribs, it also increases the structural strength between the jacket shell and the main body. After the improvement, the pouring time of molten iron is shortened, and the problems of casting porosity and cold shut-off are solved.

6. Improvement of process operation

In terms of technology, a circle of sealing strip is required to be placed around the main core of the lower half of the box, as shown in Figure 4 below: after installing the main core and accessories, a layer of sealing strip needs to be placed at the core head, as shown in Figure 5. The core head of water jacket sand core shall be drilled and sealed with asbestos ring. The purpose is to prevent molten iron from flowing to the sand core head after molten iron pouring, block and exhaust, and ensure that the gas at the sand core head is unobstructed.

The casting porosity needle at all core heads of the upper half box shall pass through the box surface to ensure smooth exhaust of the sand core after pouring molten iron. As shown in Figure 6.