Spheroidal Graphite Cast Iron (SGCI), also known as ductile iron, and traditional cast iron (often referred to as gray cast iron) are both widely used materials in various industries due to their distinctive properties and cost-effectiveness. Let’s compare these two types of cast iron to understand their differences and typical applications.

Composition

- Spheroidal Graphite Cast Iron: Consists of iron, carbon, and silicon, with the carbon primarily in the form of spherical graphite nodules. It often includes small amounts of additives like magnesium or cerium to promote the spheroidal graphite structure.

- Gray Cast Iron: Also composed of iron, carbon, and silicon, but the carbon is primarily in the form of flake graphite. It doesn’t typically require additives to achieve its graphite structure.

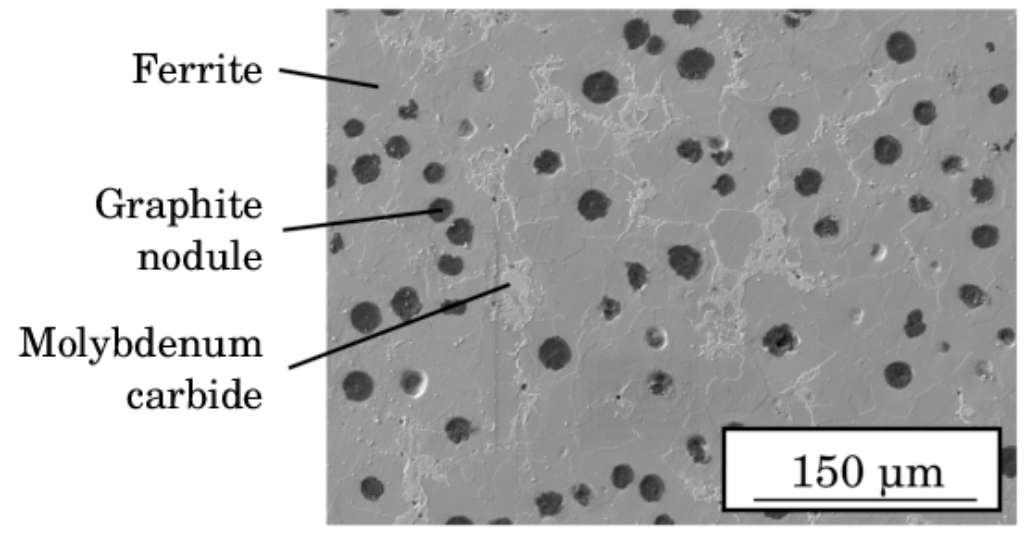

Microstructure

- Spheroidal Graphite Cast Iron: Characterized by its spherical graphite nodules within a ferritic or pearlitic matrix. The round shape of the nodules imparts significant ductility to the material.

- Gray Cast Iron: Contains flake-like graphite structures, which create stress concentration points and result in a more brittle material.

Mechanical Properties

- Strength and Ductility:

- Spheroidal Graphite Cast Iron: Exhibits higher tensile strength and much greater ductility compared to gray cast iron. The ductility resembles that of steel.

- Gray Cast Iron: While it can have high compressive strength, it has low tensile strength and low ductility.

- Toughness:

- Spheroidal Graphite Cast Iron: Generally has better impact and fatigue resistance due to its ductile nature.

- Gray Cast Iron: Less impact and fatigue resistant due to its brittle nature.

- Wear Resistance:

- Both types show good wear resistance, but this can be further enhanced in Spheroidal Graphite Cast Iron through heat treatment.

Machinability

- Spheroidal Graphite Cast Iron: Though tougher and stronger, it is still machinable, but tool wear can be higher than with gray cast iron.

- Gray Cast Iron: Excellent machinability due to the presence of graphite flakes, which act as a lubricant and help in chip breaking.

Applications

- Spheroidal Graphite Cast Iron: Widely used in applications requiring strength and ductility, such as automotive components (engine blocks, gears), pipes, and machinery parts.

- Gray Cast Iron: Common in applications where brittleness is not a major concern, like machine bases, frames, cookware, and decorative castings.

Cost and Manufacturing

- Spheroidal Graphite Cast Iron: Typically more expensive to produce than gray cast iron due to additional processing needed to create spheroidal graphite structures.

- Gray Cast Iron: Less expensive and easier to cast, making it suitable for a wide range of low-cost applications.

Conclusion

Spheroidal Graphite Cast Iron and traditional gray cast iron serve different purposes based on their properties. Spheroidal Graphite Cast Iron is preferable when strength and ductility are crucial, whereas gray cast iron is suitable for applications where compressive strength and machinability are more important than tensile strength and ductility. The choice between the two depends largely on the specific requirements of the application and cost considerations.